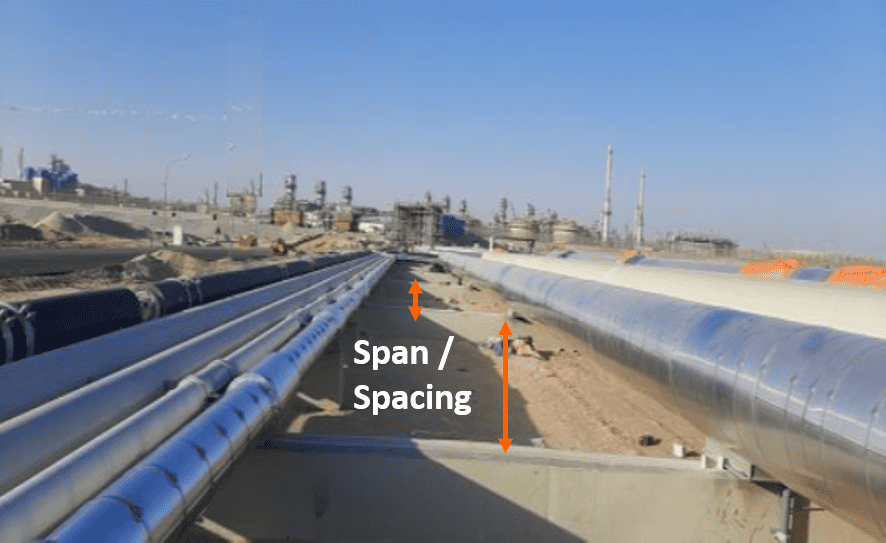

Proper pipe support span is as important as the selection of support. The distance between two consecutive support is defined as the support span. Supports are costly. Overdoing can impact your budget, and underdoing impacts plant safety.

Factor Impacting Pipe Support Span

While deciding on proper pipe support spacing, the following shall be considered.

- Weight – Gas or liquid lines

- Material – CS, SS, Coper etc.

- Insulation – type, size, thickness

- Nearby structural support

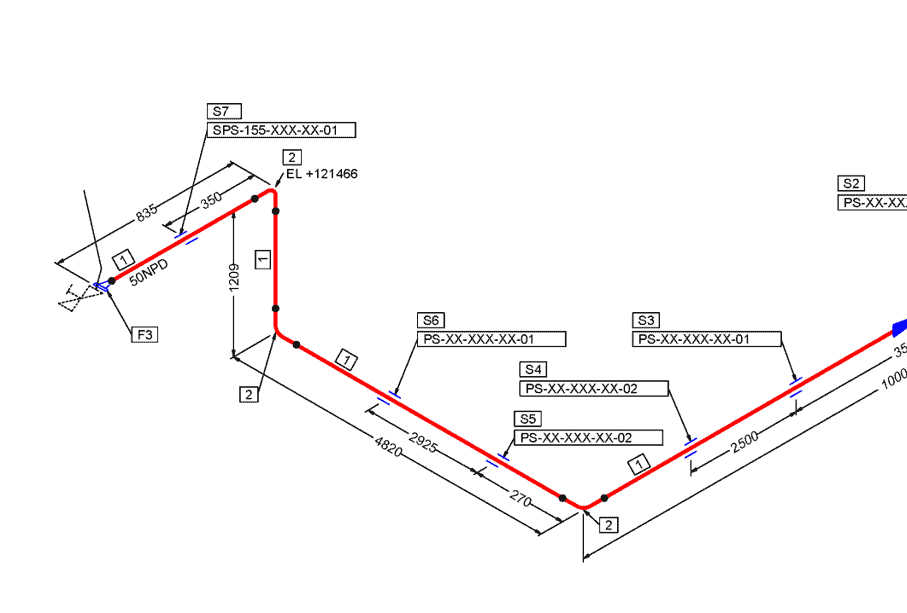

- Point of concentrated load such as valves

- Operating conditions such as temperature, duel flow condition, etc.

- Equipment connections such as pump, reciprocating compressor, heater, etc.

- Piping configuration – Unit piping vs. offsite piping

- Maximum allowable defalcation

- Cost of the support

Standard for Pipe Support Design

Refer to the below-listed standard that provides guidance on pipe support

- MSS SP-58, Materials and Design of Pipe Supports

- MSS SP-69, Selection and Application of Pipe Supports

- MSS SP-89, Fabrication and Installation of Pipe Supports

- ASME B31.1, Power Piping

- ASME B31.3, Process Piping

Pipe Support Span (Spacing) Chart

Project piping specification gives the requirement of pipe support. Depending on the project requirement Pipe Support Span (Spacing) Chart is developed. I have listed a few of them here. This Spacing chart is a kind of general guideline that gives an idea about spacing requirements. ASME B31.1 gives the following guidance for horizontal Straight turn-off standard and heavier steel pipe at a maximum operating temperature of 400 degrees centigrade. Furthermore, this spacing is not valid when a concentrated load is involved, such as a flange or valve. flow meters etc.

ASME B31.3 Span Chart for Pipe Support

| Pipe Support Spacing Chart As per ASME B31.1 | |||||

|---|---|---|---|---|---|

| Nominal Pipe Size | Diameter Nominal | Suggested Max Span for Straight Horizontal Line | |||

| NB | DN | Water Service | Steam, Air, Gas Service | ||

| NPS (Inches) | mm | m | ft | m | ft |

| 1 | 25 | 2.1 | 7 | 2.7 | 9 |

| 2 | 50 | 3 | 10 | 4 | 13 |

| 3 | 80 | 3.7 | 12 | 4.6 | 15 |

| 4 | 100 | 4.3 | 14 | 5.2 | 17 |

| 6 | 150 | 5.2 | 17 | 6.4 | 21 |

| 8 | 200 | 5.8 | 19 | 7.3 | 24 |

| 12 | 300 | 7 | 23 | 9.1 | 30 |

| 16 | 400 | 8.2 | 27 | 10.7 | 35 |

| 20 | 500 | 9.1 | 30 | 11.9 | 39 |

| 24 | 600 | 9.8 | 32 | 12.8 | 42 |

P&ID Quiz – Test yourself, Take This Quiz

Unlock New Skills with Our Best Selling Online Courses

MSS SP-69 Pipe Support Span Chart

| Pipe Support span Chart MSS SP-69 | STD Thickness Steel Pipe | Copper Tube | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Nominal Pipe Size | Diameter Nominal | Water Service | Vapor Service | Water Service | Vapor Service | ||||

| NPS (Inches) | DN (mm) | ft | m | ft | m | ft | m | ft | m |

| 1/4 | 8 | 7 | 2.1 | 8 | 2.4 | 5 | 1.5 | 5 | 1.5 |

| 3/8 | 10 | 7 | 2.1 | 8 | 2.4 | 5 | 1.5 | 6 | 1.8 |

| 1/2 | 15 | 7 | 2.1 | 8 | 2.4 | 5 | 1.5 | 6 | 1.8 |

| 3/4 | 20 | 7 | 2.1 | 9 | 2.7 | 5 | 1.5 | 7 | 2.1 |

| 1 | 25 | 7 | 2.1 | 9 | 2.7 | 6 | 1.8 | 8 | 2.4 |

| 1 ¼ | 32 | 7 | 2.1 | 9 | 2.7 | 7 | 2.1 | 9 | 2.1 |

| 1 ½ | 40 | 9 | 2.7 | 12 | 3.7 | 8 | 2 | 10 | 3 |

| 2 | 50 | 10 | 3 | 13 | 4 | 8 | 2.4 | 11 | 1.4 |

| 2 ½ | 65 | 11 | 3.4 | 14 | 4.3 | 9 | 2.7 | 13 | 4 |

| 3 | 80 | 12 | 3.7 | 15 | 4.6 | 10 | 3 | 14 | 4.3 |

| 3 ½ | 90 | 13 | 4 | 16 | 4.9 | 11 | 3.4 | 15 | 4.6 |

| 4 | 100 | 14 | 4.3 | 17 | 5.2 | 12 | 3.7 | 16 | 4.9 |

| 5 | 125 | 16 | 4.9 | 19 | 5.8 | 13 | 4 | 18 | 5.5 |

| 6 | 150 | 17 | 5.2 | 21 | 6.4 | 14 | 4.3 | 20 | 6.1 |

| 8 | 200 | 19 | 5.8 | 24 | 7.3 | 16 | 4.9 | 23 | 7 |

| 10 | 250 | 22 | 6.1 | 26 | 7.9 | 18 | 5.5 | 25 | 7.6 |

| 12 | 300 | 23 | 7 | 30 | 9.1 | 19 | 5.8 | 28 | 8.5 |

| 14 | 350 | 25 | 7.6 | 32 | 9.8 | ||||

| 16 | 400 | 27 | 8.2 | 35 | 10.7 | ||||

| 18 | 450 | 28 | 8.5 | 37 | 11.3 | ||||

| 20 | 500 | 30 | 9.1 | 39 | 11.9 | ||||

| 24 | 600 | 32 | 9.8 | 42 | 12.8 | ||||

| 30 | 750 | 33 | 10.1 | 44 | 13.4 | ||||

Are You Piping Components Master?