What is Globe Valve?

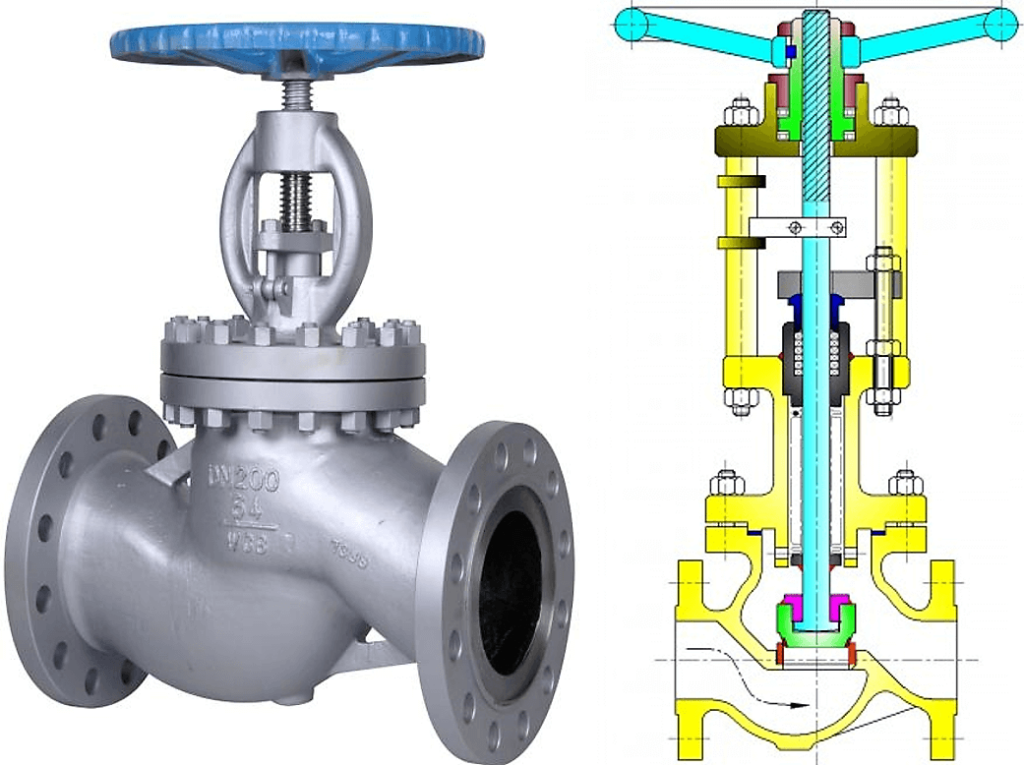

A globe valve is a linear motion valve that stops, starts, and regulates fluid flow. The globe valve disk can be removed entirely from the flow path, or it will completely close the flow path. During the opening and closing of the valve, the disc moves perpendicularly to the seat.

This movement creates the annular space between the disk and seat ring that gradually closes as the valve closes. This characteristic provides the globe valve good throttling ability required for regulating the flow.

Leakage from the globe valve seat is less as compared to the gate valve, mainly due to right-angle contact between the disc and seat ring, which allows a tighter seal between the seat and the disk.

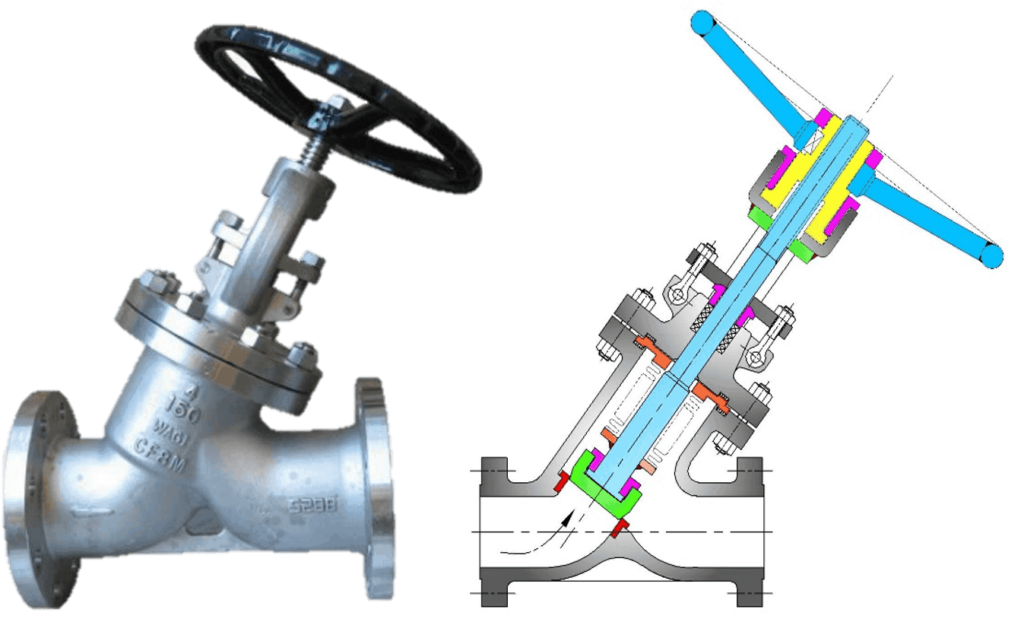

Globe Valve Diagram

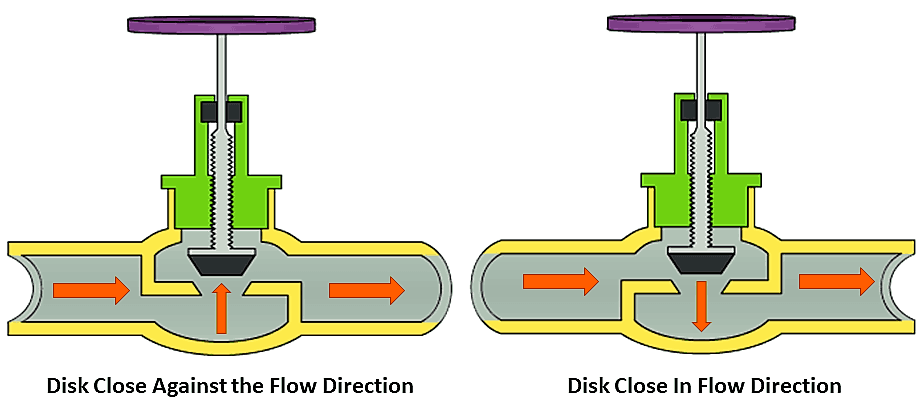

In the below globe valve diagram, you can see how the globe valve functions. The image also shows flow direction.

Unlock New Skills with Our Best Selling Online Courses

Image- By Petteri Aimonen

Globe valves can be arranged in such a way that the disk closes against the flow or in the same direction of flow.

When the disk closes in the flow direction, the fluid’s kinetic energy helps close but obstructs the opening. This characteristic is preferable when a quick-acting stop is required.

When the disk closes against the flow direction, the fluid’s kinetic energy obstructs closing but helps open the valve. This characteristic is preferable when a quick-acting start is required.

Globe Valve Parts

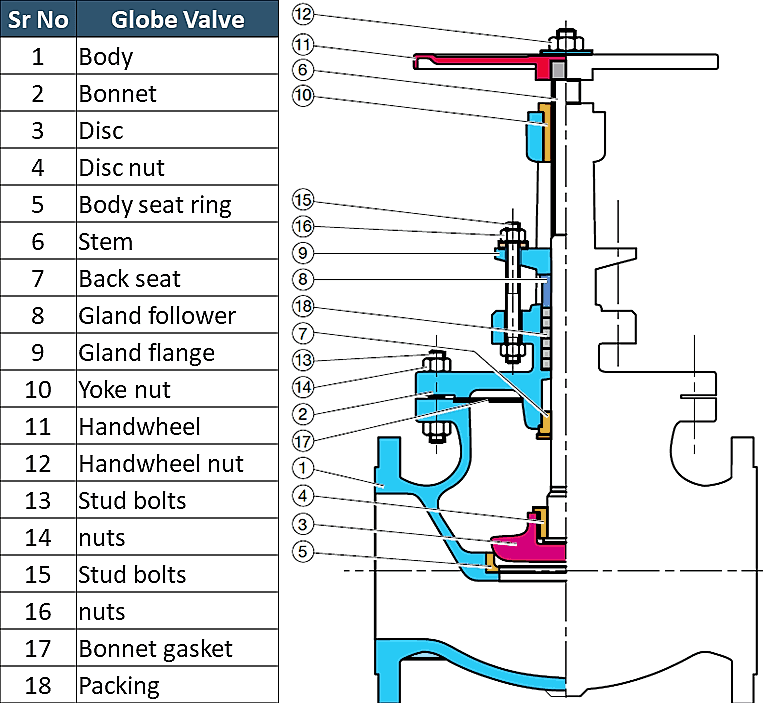

In the image below, you can see the globe valve parts such as Body, Bonnet, Stem, Seat, Disk, etc.

Image- TROUVAY & CAUVIN

Valve Quiz – Test yourself, Take This Quiz

Unlock New Skills with Our Best Selling Online Courses

Globe Valve Disk Types

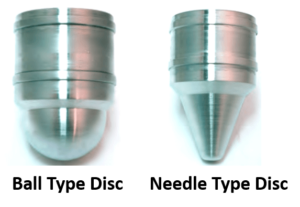

Globe valve is available in many different types of disc arrangement. The most used disk designs are listed below.

- Ball Type

- Needle Type

- Composite type

The ball disk design is used in low-pressure and low-temperature systems. It is capable of throttling flow, but in principle, it is used to stop and start the flow.

Needle disk design provides better throttling as compared to ball or composition disk design. A wide variety of long and tapered plug disks are available to suit different flow conditions.

A composition disk is used to achieve better shutoff. A hard, non-metallic insert ring is used in composition disk design.

Types of Globe Valve

Depending on the type of body, there are three types of globe valves;

- Z types

- Y types

- Angle Types

Z types Globe Valve

The simplest design and most common type is a Z-body. The Z-shaped partition inside the globular body contains the seat. The horizontal seating arrangement of the seat allows the stem and disk to travel perpendicular to the pipe axis resulting in a very high-pressure loss.

The valve seat is easily accessible through the bonnet, which is attached to a large opening at the top of the valve body. The stem passes through the bonnet like a gate valve.

This design simplifies manufacturing, installation, and repair. This type of valve is used where pressure drop is not a concern and throttling is required.

Unlock New Skills with Our Best Selling Online Courses

Y types Globe Valve

The Y-type design is a solution for the high-pressure drop problem in Z-type valves. The seat and stem are angled at approximately 45° to the pipe axis in this type. Y-body valves are used in high pressure and other critical services where pressure drop is concerned.

Angle types Globe Valve

The angle globe valve turns the flow direction by 90 degrees without using an elbow and one extra pipe weld. Disk open against the flow. This type of globe valve can also be used in the fluctuating flow condition, as they can handle the slugging effect.

Globe Valve Types based on Body Bonnet Connection

Screwed bonnet: This is the simplest design available, and it is used for inexpensive valves.

Bolted-bonnet: This is the most popular design and is used in a large number of globe valves. This requires a gasket to seal the joint between the body and the bonnet.

Welded-Bonnet: This is a popular design where disassembly is not required. They are lighter in weight than their bolted-bonnet counterparts.

Pressure-Seal Bonnet: This type is used extensively for high-pressure, high-temperature applications. The higher the body cavity pressure, the greater the force on the gasket in a pressure-seal valve.

Application of Globe valve

Globe Valves are used in systems where flow control is required, and leak tightness is also important.

- It is used in high-point vents and low-point drains when leak tightness and safety are major concerns. Otherwise, you can use a gate valve for the drain and vent.

- It can be used in Feed-water, chemical, air, lube oil, and almost all services where pressure drop is not an issue.

- This valve is also used as an automatic control valve, but in that case, the stem of the valve is a smooth stem rather than threaded and is opened and closed by the lifting action of an actuator assembly.

Advantages

- Better shut off as compared to gate valve.

- Good for frequent operation as no fear of wear of seat and disk

- Easy to repair, as the seat and disk can be accessed from the valve top

- Fast operation compares to gate valve due to shorter stroke length

- Usually operated by an automatic actuator

Disadvantages

- High head loss from two or more right-angle turns of flowing fluid within the valve body.

- Obstructions and discontinuities in the flow path lead to a high head loss.

- In a large high-pressure line, pulsations and impacts can damage internal trim parts.

- A large valve requires considerable power to open and create noise while in operation.

- It is heavier than other valves of the same pressure rating.

- Costlier compared to the gate valve.

Click here to learn about Other Types of Valve

Unlock New Skills with Our Best Selling Online Courses