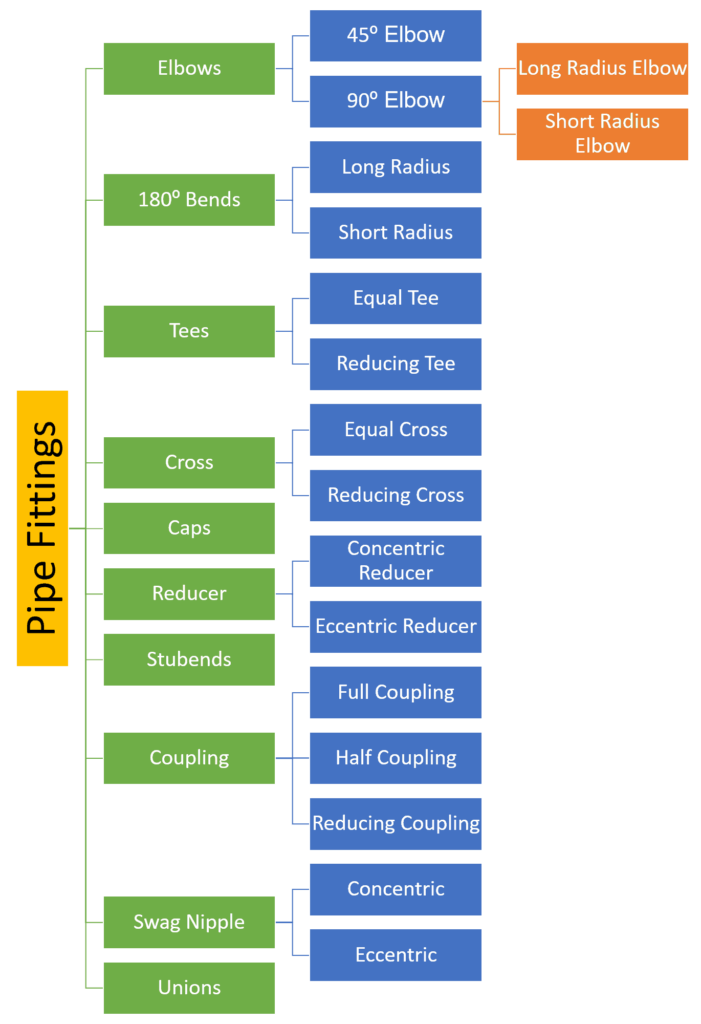

What are Pipe Fittings?

Pipe Fittings are a Piping component that helps in changing the direction of the flow, such as elbows and tees. Changes the size of the pipe, such as reducers, and reducing tees. Connect different components such as couplings and stop the flows such as Caps.

There are different types of pipe fitting used in piping. Pipe Fittings used in piping work are listed below.

- Elbow

- Tee

- Reducer

- Union

- Coupling

- Adapters

- Olet (Weldolet, Sockolet, Elbowlet, Thredolet, Nipolet, Letrolet, Swepolet)

- Valve

- Cross

- Cap

- Swage Nipple

- Plug

- Bush

- Expansion Joint

- Steam Traps

- Long Radius Bend

- Flanges

You can see the chart above that lists the most widely used standard pipe fittings. These standard fittings are either forging or wrought. Only seamless pipes are used to produce wrought fittings. Large diameter welded fittings are manufactured from the plate.

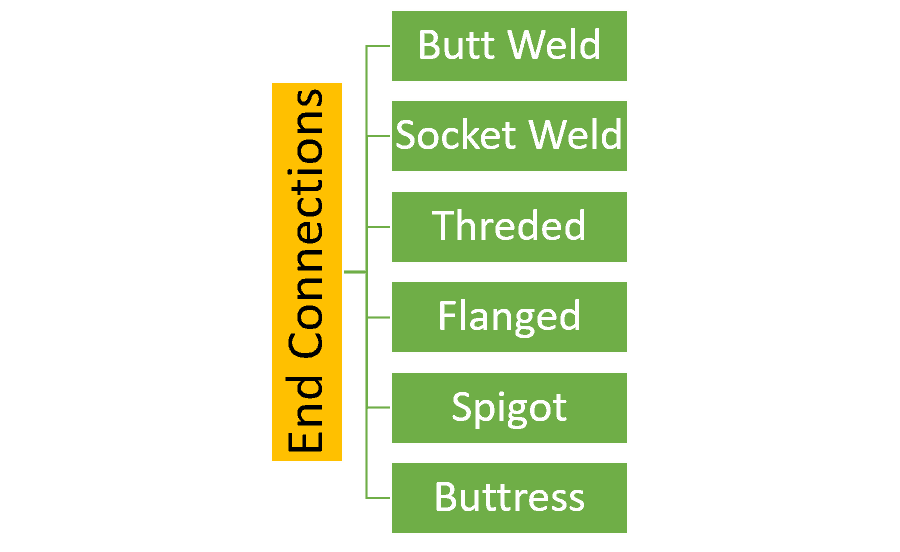

These Fittings are available in different types of end connections.

Pipe Elbow

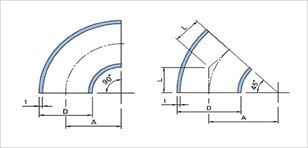

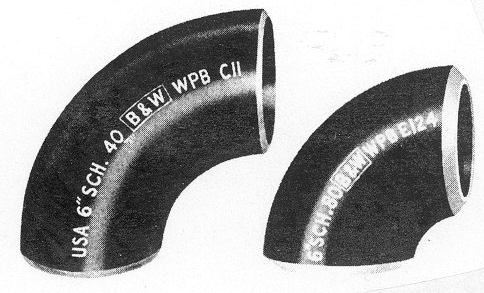

The Elbow is used more than any other pipe fittings. It provides flexibility to change the pipe direction. Elbow is mainly available in two standard types 90° and 45°. However, it Can be cut to any other degree. Elbows are available in two radius types, Short radius (1D) and Long Radius (1.5D).

Pipe FIttings Quiz – Test yourself, Take This Quiz

90 Degree Elbow

90 Degree elbow is installed between the pipe to change the direction of the pipe by 90 Degree. Available in long and short radius form.

45 Degree Elbow

45 Degree elbow is installed between the pipe to change the direction of the pipe by 45 Degree.

Long Radius Elbow

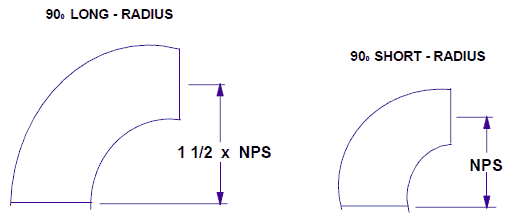

In a long radius elbow, the centreline radius is 1.5 times the nominal size of the pipe or you can say 1.5 times the diameter of the pipe. Normally long radius elbows are used in piping as pressure loss is less as compared to short radius elbows. It required more space than a short radius elbow.

Short Radius Elbow

In a short radius elbow, the centreline radius is the same as the nominal size of the pipe, or you can say one times the diameter of the pipe. Short radius elbows are used under limited space applications. However, it has a high-pressure drop due to a sudden change in the direction of flow.

Reducing Elbow

The 90 reducing elbows is designed to change direction and reduce the pipe size within a piping system. The reducing elbow eliminates one pipe fitting and reduces the welding by more than one-third. Also, the gradual reduction in diameter throughout the arc of the reducing elbow provides lower resistance to flow and reduces the effect of stream turbulence and potential internal erosion. These features prevent sizeable pressure drops in the line.

Pipe Bend

Long radius pipeline bends are used in fluid transportation lines which require pigging. Due to their long radius and smooth change of direction, the pipe bend has very less pressure drop, and a smooth flow of fluid & pig is possible. 3D and 5D Pipe bends are commonly available. Here, D is the pipe size.

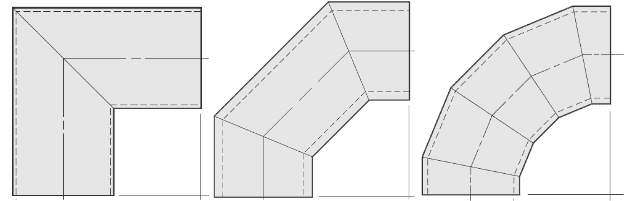

Miter Bend

Miter bends are not standard pipe fittings they are fabricated from pipes. Usually, they are preferred for sizes 10” & above because large size elbow is expensive. The use of miter bend is restricted to the low-pressure water line. Miter bend can be fabricated in 2, 3, & 5 pieces.

Returns – 180 Degree Elbow

Returning elbows are used to make a 180º change in direction. Available in short & long patterns. Returns are used in the heating coil, heat exchanger, tank vent, etc.

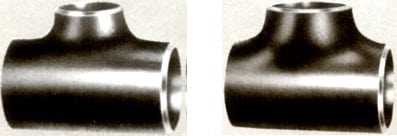

Pipe Tee

A pipe tee is used for distributing or collecting the fluid from the run pipe. It is a short piece of pipe with a 90-degree branch at the center. Two types of Tee are used in piping: Equal / Straight Tee and Reducing / Unequal Tee.

Straight Tee

In straight tee, the diameter of the branch is the same as the diameter of the Run (Header) Pipe.

Reducing Tee

In reducing tee, the diameter of the branch size is smaller than the diameter of the Run (Header) Pipe

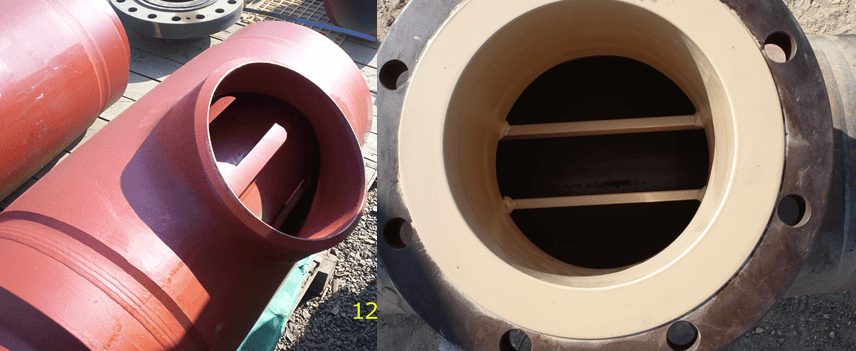

Barred Tee

A barred tee, also known as a scrapper tee, is used in pigged pipelines. The tee branch has a restriction bar welded internally to prevent the pig or scrapper from entering the branch. The bars are welded in the branch in a way that it will allow restriction-free passage of the pig from the run pipe.

Wye Tee / Lateral

It is a type of Tee that has a branch at a 45° angle or an angle other than 90°. Wye tee allows one pipe to be joined to another at a 45° angle. This type of tee reduces friction and turbulence that could hamper the flow. Wye tee is also known as a lateral.

Cross

Cross is also known as four-way pipe fitting. A cross has one inlet and three outlets (or vice versa). Generally, crosses are not used in process piping to transport fluid. But forged crosses are common in the firewater sprinkler line.

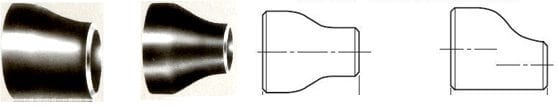

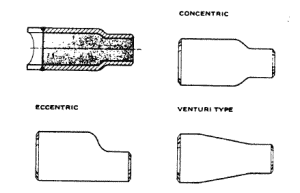

Pipe Reducers

A pipe reducer changes the size of the pipe. There are two types of reducers used in piping Concentric & Eccentric.

Concentric Pipe Reducer or Conical Reducer

In a Concentric reducer, also known as a conical reducer, the center of both ends is on the same axis. It maintains the centerline elevation of the pipeline. When the center lines of the larger and smaller pipe are to be maintained the same, concentric reducers are used.

Eccentric Reducer

In the Eccentric reducer, the center of both ends is on a different axis, as shown in the image. It maintains the BOP (bottom of pipe) elevation of the pipeline. When one of the outside surfaces of the pipeline is to be maintained the same, eccentric reducers are required.

Offset = ( Larger ID – Smaller ID) / 2

Swage Reducer

The swage is like reducers but small in size and used to connect pipes to smaller screwed or socket welded pipes. Like reducers, they are also available in concentric & eccentric types. Swages are available in different end types. Such as both plain ends or one plain and one threaded end.

Pipe Caps

The cap covers the end of a pipe. Pipe caps are used at the dead end of the piping system. It is also used in piping headers for future connections.

Stub Ends

Stub ends are used with a lap joint flange. In this type of flange, the stub is butt welded to the pipe, whereas the flange is freely moved over the stub end. It is basically a flange part but covered under ASME B16.9, which is why it is considered pipe fittings.

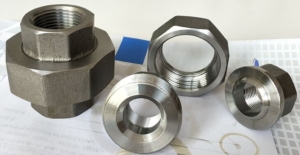

Piping Union

Unions are used as an alternative to flanges connection in low-pressure small bore piping where the dismantling of the pipe is required more often. Unions can be threaded ends, or socket weld ends. There are three pieces in a union, a nut, a female end, and a male end. When the female and male ends are joined, the nuts provide the necessary pressure to seal the joint.

Pipe Coupling

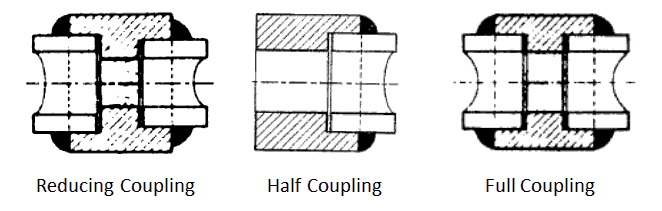

There are three types of coupling available;

- Full Coupling

- Half Coupling

- Reducing Coupling

Full Coupling

Full Coupling is used for connecting small bore pipes. It is used to connect pipe to pipe or pipe to swage or nipple. It can be threaded or socket ends types.

Half Coupling

Half Coupling is used for small bore branching from a vessel or large pipe. It can be threaded or socket type. It has a socket or thread end on only one side.

Reducing Coupling

Reducing coupling is used to connect two different sizes of pipe. It is like a concentric reducer that maintains a centerline of the pipe but is small in size.

Pipe Nipple

The nipple is a short pipe stub with a male pipe thread at each end or at one end. It is used for connecting two other fittings. Nipples are used for connecting pipes, hoses, and valves. Pipe nipples are used in low-pressure piping.

Socket weld and Threaded Pipe Fittings

Socket weld and Threaded Pipe Fittings are forged products and classified based on their pressure-temperature rating. They are available from NPS 1/8” to 4”. These fittings are available in four pressure-temperature rating classes.

- 2000 class fittings are available only in threaded type.

- 3000 & 6000 class fittings are available in both Threaded and Socket Weld types.

- 9000 class fittings are available in only the socket weld type.

These fittings are used for small bore and low-pressure piping.

Socket Weld Elbow

Tee and Cross Socket Weld Type

Threaded Pipe Fittings

Pipe Fittings dimensions of the fittings must meet the requirements of the standard,

- For Wrought Product (WP) Dimension is covered in

- ASME B16.9- which is standard for Factory-made Wrought Butt-welding Fittings for size NPS 1⁄₂ to NPS 48” and

- And B16.28- which is standard for Wrought Steel Butt-Welding Short Radius Elbows and Returns for size NPS 1⁄₂ to NPS 24”

- For Forged Fittings, Dimensions are covered in,

- ASME B16.11- a standard for Forged Steel Fittings that covers Socket Welding and Threaded fittings

Special Thanks to Sophie Shi & Mr. Tom for providing Images. You can visit their website for further product inquiries.

Sophie Shi – www.lianfachina.com

Mr. Tom – http://sinopipefittings.com

Are You Piping Components Master?