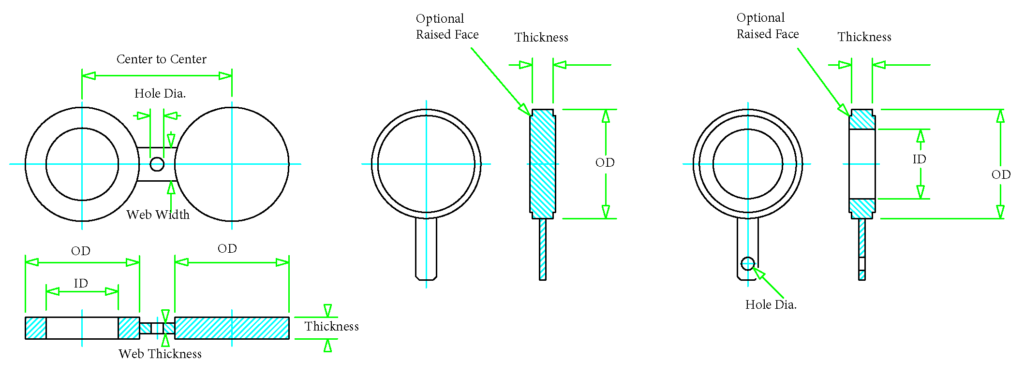

In this article, I have covered the spectacle Blind Dimensions. A spectacle blind is used in piping for positive isolation of the section of a line or equipment during maintenance and shutdown.

ASME B16.48 standard that covers Line Blanks. This standard covers Spectacle Blind, Spades, and Spacers dimensions with pressure class 150, 300, 600, 900, 1500, and 2500 as listed in ASME B16.5.

Spectacle Blind Dimensions

Class 150 Spectacle blind Dimensions

| Size in Inch | Size in MM | Internal Dia. | Outer Dia. | Center to Center | Thick. | Web Width | Web Thick. | Hole Dia | Spec. Blind Weight in Kg | Paddle Blank Weight in kg | Paddle Spacer Blank Weight in kg |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1/2 | 15 | 16 | 45 | 60 | 3 | 38 | 2 | 15.875 | 0.07 | 0.03 | 0.03 |

| 3/4 | 20 | 21 | 54 | 70 | 3 | 38 | 2 | 15.875 | 0.1 | 0.05 | 0.04 |

| 1 | 25 | 27 | 64 | 80 | 3 | 38 | 2 | 15.875 | 0.14 | 0.07 | 0.06 |

| 1 1/4 | 32 | 42 | 73 | 90 | 6.4 | 38 | 4 | 15.875 | 0.35 | 0.21 | 0.14 |

| 1 1/2 | 40 | 48 | 83 | 100 | 6.4 | 38 | 4 | 15.875 | 0.46 | 0.27 | 0.18 |

| 2 | 50 | 61 | 102 | 120 | 6.4 | 51 | 4 | 19.05 | 0.68 | 0.41 | 0.26 |

| 2 1/2 | 65 | 73 | 107 | 140 | 6.4 | 51 | 4 | 19.05 | 0.7 | 0.46 | 0.24 |

| 3 | 80 | 89 | 133 | 150 | 6.4 | 64 | 4 | 19.05 | 1.1 | 0.71 | 0.39 |

| 3 1/2 | 90 | 102 | 159 | 175 | 9.7 | 64 | 5 | 19.05 | 2.44 | 1.54 | 0.9 |

| 4 | 100 | 114 | 172 | 190 | 9.7 | 64 | 5 | 19.05 | 2.81 | 1.8 | 1.01 |

| 5 | 130 | 141 | 194 | 215 | 9.7 | 76 | 5 | 22.225 | 3.37 | 2.29 | 1.08 |

| 6 | 150 | 168 | 219 | 240 | 12.7 | 76 | 7 | 22.225 | 5.39 | 3.82 | 1.57 |

| 8 | 200 | 219 | 276 | 300 | 12.7 | 76 | 10 | 22.225 | 8.32 | 6.07 | 2.25 |

| 10 | 250 | 273 | 337 | 360 | 15.7 | 102 | 12 | 25.4 | 15.04 | 11.19 | 3.84 |

| 12 | 300 | 324 | 406 | 430 | 19.1 | 102 | 15 | 25.4 | 26.95 | 19.77 | 7.18 |

| 14 | 350 | 356 | 448 | 475 | 19.1 | 108 | 15 | 28.575 | 32.94 | 24.07 | 8.87 |

| 16 | 400 | 406 | 511 | 540 | 22.4 | 108 | 17 | 28.575 | 50.27 | 36.73 | 13.54 |

| 18 | 450 | 457 | 546 | 580 | 25.4 | 114 | 20 | 31.75 | 61.79 | 47.55 | 14.23 |

| 20 | 500 | 508 | 603 | 635 | 28.4 | 121 | 22 | 31.75 | 83.67 | 64.85 | 18.82 |

| 24 | 600 | 610 | 714 | 750 | 31.8 | 140 | 24 | 34.925 | 129.3 | 101.8 | 27.49 |

Gasket Quiz – Test yourself, Take This Quiz

Class 300 Spectacle blind Flange Dimensions

| Size in Inch | Size in MM | Internal Dia. | Outer Dia. | Center to Center | Thick. | Web Width | Web Thick. | Hole Dia | Spec. Blind Weight in Kg | Paddle Blank Weight in kg | Paddle Spacer Blank Weight in kg |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1/2 | 15 | 16 | 51 | 65 | 6.4 | 38 | 4 | 15.875 | 0.19 | 0.1 | 0.09 |

| 3/4 | 20 | 21 | 64 | 80 | 6.4 | 38 | 4 | 19.05 | 0.31 | 0.16 | 0.14 |

| 1 | 25 | 27 | 70 | 90 | 6.4 | 38 | 4 | 19.05 | 0.36 | 0.19 | 0.16 |

| 1 1/4 | 32 | 42 | 79 | 100 | 6.4 | 38 | 4 | 19.05 | 0.43 | 0.25 | 0.17 |

| 1 1/2 | 40 | 48 | 92 | 115 | 6.4 | 38 | 4 | 22.225 | 0.58 | 0.34 | 0.24 |

| 2 | 50 | 61 | 108 | 125 | 9.7 | 51 | 5 | 19.05 | 1.19 | 0.71 | 0.48 |

| 2 1/2 | 65 | 73 | 127 | 150 | 9.7 | 51 | 5 | 22.225 | 1.64 | 0.98 | 0.65 |

| 3 | 80 | 89 | 146 | 170 | 9.7 | 64 | 5 | 22.225 | 2.11 | 1.29 | 0.81 |

| 3 1/2 | 90 | 102 | 162 | 185 | 12.7 | 64 | 7 | 22.225 | 3.35 | 2.09 | 1.26 |

| 4 | 100 | 114 | 178 | 200 | 12.7 | 64 | 7 | 22.225 | 4.01 | 2.52 | 1.49 |

| 5 | 130 | 141 | 213 | 235 | 15.7 | 76 | 8 | 22.225 | 6.98 | 4.47 | 2.51 |

| 6 | 150 | 168 | 248 | 270 | 15.7 | 76 | 8 | 22.225 | 9.34 | 6.06 | 3.28 |

| 8 | 200 | 219 | 305 | 330 | 22.4 | 76 | 17 | 25.4 | 19.42 | 13.08 | 6.33 |

| 10 | 250 | 273 | 359 | 385 | 25.4 | 102 | 20 | 28.575 | 29.22 | 20.55 | 8.66 |

| 12 | 300 | 324 | 419 | 450 | 28.4 | 102 | 22 | 31.75 | 43.9 | 31.31 | 12.58 |

| 14 | 350 | 356 | 483 | 515 | 31.8 | 108 | 24 | 31.75 | 67.86 | 46.58 | 21.27 |

| 16 | 400 | 406 | 536 | 570 | 38.1 | 108 | 29 | 34.925 | 98.04 | 68.74 | 29.3 |

| 18 | 450 | 457 | 594 | 630 | 41.1 | 114 | 31 | 34.925 | 128.23 | 91.06 | 37.16 |

| 20 | 500 | 508 | 651 | 685 | 44.5 | 121 | 34 | 34.925 | 164.75 | 118.43 | 46.31 |

| 24 | 600 | 610 | 772 | 810 | 50.8 | 140 | 39 | 41.275 | 261.55 | 190.13 | 71.42 |

Unlock New Skills with Our Best Selling Online Courses

Class 600 Spectacle blind Flange Dimensions

| Size in Inch | Size in MM | Internal Dia. | Outer Dia. | Center to Center | Thick. | Web Width | Web Thick. | Hole Dia | Spec. Blind Weight in Kg | Paddle Blank Weight in kg | Paddle Spacer Blank Weight in kg |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1/2 | 15 | 16 | 51 | 65 | 6.4 | 38 | 4 | 15.875 | 0.19 | 0.1 | 0.09 |

| 3/4 | 20 | 21 | 64 | 80 | 6.4 | 38 | 4 | 19.05 | 0.31 | 0.16 | 0.14 |

| 1 | 25 | 27 | 70 | 90 | 6.4 | 57 | 4 | 19.05 | 0.36 | 0.19 | 0.16 |

| 1 1/4 | 32 | 37 | 79 | 100 | 9.7 | 57 | 5 | 19.05 | 0.67 | 0.38 | 0.29 |

| 1 1/2 | 40 | 43 | 92 | 115 | 9.7 | 67 | 5 | 22.225 | 0.91 | 0.51 | 0.4 |

| 2 | 50 | 55 | 108 | 125 | 9.7 | 57 | 5 | 19.05 | 1.23 | 0.71 | 0.52 |

| 2 1/2 | 65 | 67 | 127 | 150 | 12.7 | 67 | 7 | 22.225 | 2.21 | 1.28 | 0.92 |

| 3 | 80 | 83 | 146 | 170 | 12.7 | 67 | 7 | 22.225 | 2.85 | 1.7 | 1.15 |

| 3 1/2 | 90 | 96 | 159 | 185 | 15.7 | 76 | 8 | 25.4 | 4.07 | 2.49 | 1.58 |

| 4 | 100 | 108 | 191 | 215 | 15.7 | 76 | 8 | 25.4 | 6.04 | 3.59 | 2.44 |

| 5 | 130 | 135 | 238 | 265 | 19.1 | 86 | 10 | 28.575 | 11.4 | 6.79 | 4.6 |

| 6 | 150 | 162 | 264 | 290 | 22.4 | 86 | 12 | 28.575 | 15.91 | 9.8 | 6.11 |

| 8 | 200 | 212 | 318 | 350 | 28.4 | 95 | 22 | 31.75 | 28.05 | 18.03 | 10.01 |

| 10 | 250 | 265 | 397 | 430 | 35.1 | 105 | 27 | 34.925 | 54 | 34.74 | 19.26 |

| 12 | 300 | 315 | 454 | 490 | 41.1 | 105 | 31 | 34.925 | 80.78 | 53.2 | 27.58 |

| 14 | 350 | 346 | 489 | 525 | 44.5 | 114 | 34 | 38.1 | 100.19 | 66.82 | 33.36 |

| 16 | 400 | 397 | 562 | 605 | 50.8 | 124 | 39 | 41.275 | 151.24 | 100.76 | 50.48 |

| 18 | 450 | 448 | 610 | 655 | 53.8 | 133 | 41 | 44.45 | 183.62 | 125.71 | 57.9 |

| 20 | 500 | 497 | 679 | 725 | 63.5 | 133 | 48 | 44.45 | 269.2 | 183.85 | 85.35 |

| 24 | 600 | 597 | 787 | 840 | 73.2 | 152 | 55 | 50.8 | 405.6 | 284.72 | 120.88 |

Class 900 Spectacle blind Flange Dimensions

| Size in Inch | Size in MM | Internal Dia. | Outer Dia. | Center to Center | Thick. | Web Width | Web Thick. | Hole Dia | Spec. Blind Weight in Kg | Paddle Blank Weight in kg | Paddle Spacer Blank Weight in kg |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1/2 | 15 | 16 | 60 | 80 | 6.4 | 38 | 4 | 22.225 | 0.27 | 0.14 | 0.13 |

| 3/4 | 20 | 21 | 67 | 90 | 6.4 | 41 | 4 | 22.225 | 0.34 | 0.18 | 0.16 |

| 1 | 25 | 27 | 76 | 100 | 6.4 | 57 | 4 | 25.4 | 0.43 | 0.23 | 0.2 |

| 1 1/4 | 32 | 37 | 86 | 110 | 9.7 | 57 | 5 | 25.4 | 0.81 | 0.45 | 0.36 |

| 1 1/2 | 40 | 43 | 95 | 125 | 9.7 | 67 | 5 | 28.575 | 0.98 | 0.54 | 0.43 |

| 2 | 50 | 55 | 140 | 165 | 12.7 | 57 | 7 | 25.4 | 2.88 | 1.56 | 1.32 |

| 2 1/2 | 65 | 67 | 162 | 190 | 12.7 | 67 | 7 | 28.575 | 3.82 | 2.09 | 1.73 |

| 3 | 80 | 83 | 165 | 190 | 15.7 | 67 | 8 | 25.4 | 4.68 | 2.68 | 2 |

| 4 | 100 | 108 | 203 | 235 | 19.1 | 76 | 10 | 31.75 | 8.48 | 4.94 | 3.54 |

| 5 | 130 | 135 | 244 | 280 | 22.4 | 86 | 12 | 34.925 | 14.18 | 8.37 | 5.81 |

| 6 | 150 | 162 | 286 | 320 | 25.4 | 86 | 13 | 31.75 | 21.9 | 13.04 | 8.86 |

| 8 | 200 | 212 | 356 | 395 | 35.1 | 95 | 27 | 38.1 | 45.96 | 27.93 | 18.02 |

| 10 | 250 | 265 | 432 | 470 | 41.1 | 105 | 31 | 38.1 | 78.21 | 48.16 | 30.04 |

| 12 | 300 | 315 | 495 | 535 | 47.8 | 105 | 36 | 38.1 | 117.31 | 73.55 | 43.76 |

| 14 | 350 | 346 | 518 | 560 | 53.8 | 114 | 41 | 41.275 | 140.86 | 90.65 | 50.2 |

| 16 | 400 | 397 | 572 | 615 | 60.5 | 124 | 46 | 44.45 | 188.73 | 124.31 | 64.42 |

| 18 | 450 | 448 | 635 | 685 | 66.5 | 133 | 50 | 50.8 | 252.97 | 168.39 | 84.57 |

| 20 | 500 | 497 | 696 | 750 | 73.2 | 133 | 55 | 53.975 | 331.81 | 222.68 | 109.13 |

| 24 | 600 | 597 | 835 | 900 | 88.9 | 152 | 67 | 66.675 | 579.52 | 389.25 | 190.27 |

Unlock New Skills with Our Best Selling Online Courses

Class 1500 Spectacle blind Flange Dimensions

| Size in Inch | Size in MM | Internal Dia. | Outer Dia. | Center to Center | Thick. | Web Width | Web Thick. | Hole Dia | Spec. Blind Weight in Kg | Paddle Blank Weight in kg | Paddle Spacer Blank Weight in kg |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1/2 | 15 | 16 | 61 | 80 | 6.4 | 38 | 4 | 22.225 | 0.28 | 0.14 | 0.13 |

| 3/4 | 20 | 21 | 67 | 90 | 9.7 | 41 | 5 | 22.225 | 0.52 | 0.27 | 0.24 |

| 1 | 25 | 27 | 76 | 100 | 9.7 | 64 | 5 | 25.4 | 0.65 | 0.35 | 0.3 |

| 1 1/4 | 32 | 35 | 86 | 110 | 9.7 | 64 | 5 | 25.4 | 0.82 | 0.45 | 0.37 |

| 1 1/2 | 40 | 41 | 95 | 125 | 12.7 | 70 | 7 | 28.575 | 1.3 | 0.71 | 0.58 |

| 2 | 50 | 53 | 140 | 165 | 12.7 | 70 | 7 | 25.4 | 2.9 | 1.56 | 1.33 |

| 2 1/2 | 65 | 63 | 162 | 190 | 15.7 | 76 | 8 | 28.575 | 4.78 | 2.58 | 2.19 |

| 3 | 80 | 78 | 172 | 205 | 19.1 | 76 | 10 | 31.75 | 6.36 | 3.54 | 2.81 |

| 4 | 100 | 102 | 206 | 240 | 22.4 | 89 | 12 | 34.925 | 10.47 | 5.96 | 4.5 |

| 5 | 130 | 128 | 251 | 290 | 28.4 | 89 | 15 | 41.275 | 19.55 | 11.23 | 8.31 |

| 6 | 150 | 154 | 279 | 320 | 35.1 | 89 | 18 | 38.1 | 29.08 | 17.15 | 11.93 |

| 8 | 200 | 203 | 349 | 395 | 41.1 | 102 | 31 | 44.45 | 52.23 | 31.43 | 20.8 |

| 10 | 250 | 255 | 432 | 480 | 50.8 | 114 | 39 | 50.8 | 98.33 | 59.53 | 38.79 |

| 12 | 300 | 303 | 518 | 570 | 60.5 | 114 | 46 | 53.975 | 169.01 | 101.94 | 67.06 |

| 14 | 350 | 333 | 575 | 635 | 66.5 | 127 | 50 | 60.325 | 229.84 | 138.07 | 91.76 |

| 16 | 400 | 381 | 638 | 705 | 76.2 | 133 | 58 | 66.675 | 320.1 | 194.78 | 125.32 |

| 18 | 450 | 429 | 702 | 775 | 85.9 | 146 | 65 | 73.025 | 432.4 | 265.84 | 166.56 |

| 20 | 500 | 478 | 752 | 830 | 95.3 | 152 | 72 | 79.375 | 540.14 | 338.44 | 201.7 |

| 24 | 600 | 575 | 899 | 990 | 111.3 | 178 | 84 | 92.075 | 898.71 | 564.9 | 333.8 |

Class 2500 Spectacle blind Flange Dimensions

| Size in Inch | Size in MM | Internal Dia. | Outer Dia. | Center to Center | Thick. | Web Width | Web Thick. | Hole Dia | Spec. Blind Weight in Kg | Paddle Blank Weight in kg | Paddle Spacer Blank Weight in kg |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1/2 | 15 | 16 | 67 | 90 | 9.7 | 38 | 5 | 22.225 | 0.53 | 0.27 | 0.25 |

| 3/4 | 20 | 21 | 73 | 95 | 9.7 | 41 | 5 | 22.225 | 0.62 | 0.32 | 0.29 |

| 1 | 25 | 27 | 83 | 110 | 9.7 | 64 | 5 | 25.4 | 0.79 | 0.41 | 0.37 |

| 1 1/4 | 32 | 35 | 102 | 130 | 12.7 | 64 | 7 | 28.575 | 1.56 | 0.82 | 0.73 |

| 1 1/2 | 40 | 41 | 114 | 145 | 15.7 | 70 | 8 | 31.75 | 2.39 | 1.28 | 1.11 |

| 2 | 50 | 53 | 143 | 170 | 15.7 | 70 | 8 | 28.575 | 3.75 | 2.01 | 1.73 |

| 2 1/2 | 65 | 63 | 165 | 195 | 19.1 | 76 | 10 | 31.75 | 6.05 | 3.26 | 2.78 |

| 3 | 80 | 78 | 194 | 230 | 22.4 | 76 | 12 | 34.925 | 9.73 | 5.29 | 4.43 |

| 4 | 100 | 102 | 232 | 275 | 28.4 | 89 | 22 | 41.275 | 17.34 | 9.59 | 7.74 |

| 5 | 130 | 128 | 276 | 325 | 35.1 | 89 | 27 | 47.625 | 29.97 | 16.79 | 13.17 |

| 6 | 150 | 154 | 314 | 370 | 41.1 | 89 | 31 | 53.975 | 44.77 | 25.44 | 19.32 |

| 8 | 200 | 198 | 384 | 440 | 53.8 | 102 | 41 | 53.975 | 86.39 | 49.82 | 36.57 |

| 10 | 250 | 248 | 473 | 540 | 66.5 | 114 | 50 | 66.675 | 161.18 | 93.43 | 67.74 |

| 12 | 300 | 289 | 546 | 620 | 79.2 | 114 | 60 | 73.025 | 255.01 | 148.27 | 106.73 |

Disclaimer – Please check with ASME B16.5 Before using.