Welcome to the hardhatengineer short video. In this video, you will learn about pipe support span. Please do like and share this video, and don’t forget to subscribe.

Let’s start with the video.

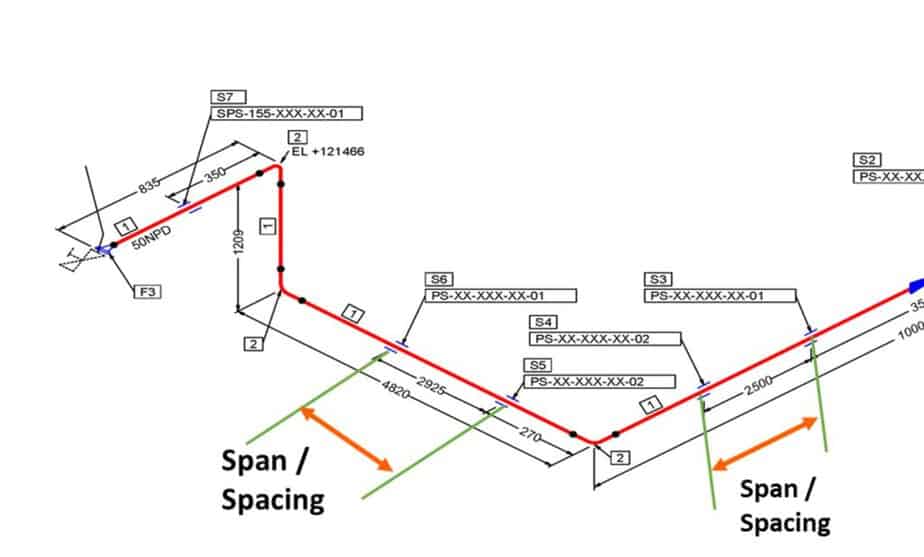

The distance between two consecutive pipe support is called the support span. For example, here in the image, you can see that this line is supported at regular intervals.

Proper pipe support span is as essential as the selection of support. If a pipeline is not supported correctly, it may result in excessive sagging and vibration and may displace from the location. Supports are costly. Overdoing can impact your budget, and underdoing impacts plant safety.

Many factors impact spacing between two Pipe Supports. Let’s see some of them.

The weight of the pipeline is one of the major contributing factors to supporting location selection. Whether the line is carrying Gas or liquid greatly impacts its weight. Similarly, the size and thickness of the pipe also contribute to the overall weight.

Next is material type. Material such as Carbon steel needs fewer supports than Stainless Steel and copper.

Insulation types such as cold or hot, their size and thickness add additional weight to the support, so insulated lines have more supports than non-insulated ones.

Nearby structural support can influence the support span to get the cost advantage of already available support.

P&ID Quiz – Test yourself, Take This Quiz

Point of concentrated loads such as valves and other metering instruments need additional support to prevent large deflection.

Operating conditions such as temperature, duel flow condition, equipment connection such as pump, reciprocating compressor, heater, etc., also required additional consideration while providing support.

A piping configuration such as Unit piping vs. offsite piping is also a factor. For example, pipe support spacing will be more for offsite piping than unit piping as the former has fewer direction changes.

Project specification for maximum allowable defalcation and the support cost are also factors for deciding the proper pipe support span.

This is the end of the video. Please visit my website hardhatengineer.com to learn more on this topic, such as applicable codes and suggested span charts. See you soon with the next short video. Goodbye, take care.

Are You Piping Components Master?