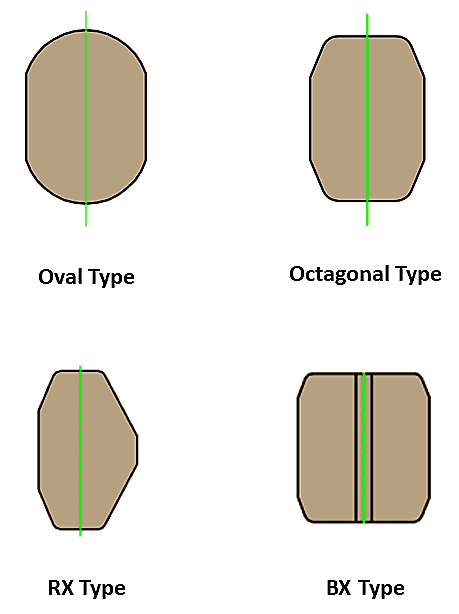

Ring gaskets are also known as RTJ gaskets or O-ring Gaskets. These gaskets are used for high-pressure services. They are solid rings of metal (cut from plate, pipe, or a forged ring) in different cross-sections such as the oval, round, and octagonal.

A special RTJ gasket comes with a hole in the center for pressure equalization in the subsea pipeline application. You can see the different types of RTJ gaskets in the image below.

Ring Joint Gaskets are used with Ring Type Joint (RTJ) flanges. High surface stress is developed between an RTJ gasket and the flange groove when the RTJ gasket is bolted to a flange. This leads to the plastic deformation of this gasket.

Thus, the hardness of the gasket is kept less than the hardness of the flange groove. The only thing you have to take care of is that the hardness of the gasket shall always be less than flange material by at least 50 BHN. For more info, visit –Lamons

RTJ Gasket Materials and Hardness

A list of materials that can be used for metallic gaskets and the maximum acceptable hardness for these materials is given in ASME B16.20. Refer to the below table for more information.

| GASKET MATERIALS | BRINELL HARDNESS NUMBER (max) | ROCKWELL HARDNESS NUMBER -B Scale (max) | IDENTIFICATION |

|---|---|---|---|

| Soft iron | 90 | 56 | D |

| Low carbon steel | 120 | 68 | S |

| 4-6% Chrome 1/2% molybdenum | 130 | 72 | F5 |

| Type 410 Stainless Steel | 170 | 86 | S410 |

| Type 304 Stainless Steel | 160 | 83 | S304 |

| Type 316 Stainless Steel | 160 | 83 | S316 |

| Type 347 Stainless Steel | 160 | 83 | S347 |

| Type 410 Stainless Steel | 170 | 86 | S410 |

Gasket Quiz – Test yourself, Take This Quiz

Unlock New Skills with Our Best Selling Online Courses

RTJ Gasket Dimension Chart

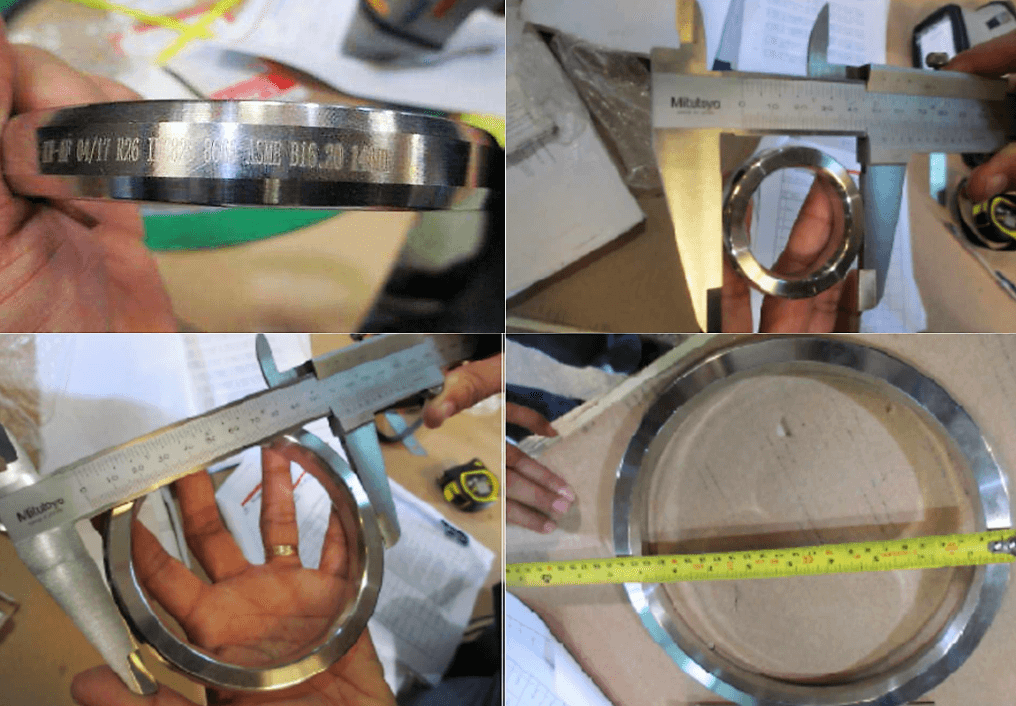

Dimensions of RTJ Ring gaskets are covered in ASME B16.20. You can see the dimension chart below. Please check with the standard before using the chart.

During dimension inspection of the gasket, you should check for

- Diameter – Inside / Outside

- Width / Height

- Thickness

- Centering ring dimensions

- Permissible Variations of Gasket dimensions are covered in ASME B16.20.

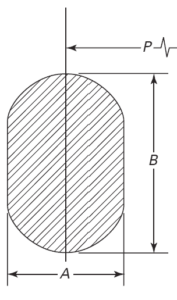

Oval Ring Metal Gasket Dimensions

| R no | P-Pitch Dia | A-Width | B-Height Oval Ring |

|---|---|---|---|

| R-11 | 34.14 | 6.35 | 11.2 |

| R-12 | 39.7 | 7.95 | 14.2 |

| R-13 | 42.88 | 7.95 | 14.2 |

| R-14 | 44.45 | 7.95 | 14.2 |

| R-15 | 47.63 | 7.95 | 14.2 |

| R-16 | 50.8 | 7.95 | 14.2 |

| R-17 | 57.15 | 7.95 | 14.2 |

| R-18 | 60.33 | 7.95 | 14.2 |

| R-19 | 65.1 | 7.95 | 14.2 |

| R-20 | 68.28 | 7.95 | 14.2 |

| R-21 | 72.24 | 11.13 | 17.5 |

| R-22 | 82.55 | 7.95 | 14.2 |

| R-23 | 82.55 | 11.13 | 17.5 |

| R-24 | 95.25 | 11.13 | 17.5 |

| R-25 | 101.6 | 7.95 | 14.2 |

| R-26 | 101.6 | 11.13 | 17.5 |

| R-27 | 107.95 | 11.13 | 17.5 |

| R-28 | 111.13 | 12.7 | 19.1 |

| R-29 | 114.3 | 7.95 | 14.2 |

| R-30 | 117.48 | 11.13 | 17.5 |

| R-31 | 123.83 | 11.13 | 17.5 |

| R-32 | 127 | 12.7 | 19.1 |

| R-33 | 131.78 | 7.95 | 14.2 |

| R-34 | 131.78 | 11.13 | 17.5 |

| R-35 | 136.53 | 11.13 | 17.5 |

| R-36 | 149.23 | 7.95 | 14.2 |

| R-37 | 149.23 | 11.13 | 17.5 |

| R-38 | 157.18 | 15.88 | 22.4 |

| R-39 | 161.93 | 11.13 | 17.5 |

| R-40 | 171.45 | 7.95 | 14.2 |

| R-41 | 180.98 | 11.13 | 17.5 |

| R-42 | 190.5 | 19.05 | 25.4 |

| R-43 | 193.68 | 7.95 | 14.2 |

| R-44 | 193.68 | 11.13 | 17.5 |

| R-45 | 211.15 | 11.13 | 17.5 |

| R-46 | 211.15 | 12.7 | 19.1 |

| R-47 | 228.6 | 19.05 | 25.4 |

| R-48 | 247.65 | 7.95 | 14.2 |

| R-49 | 269.88 | 11.13 | 17.5 |

| R-50 | 269.88 | 15.88 | 22.4 |

| R-51 | 279.4 | 22.23 | 28.7 |

| R-52 | 304.8 | 7.95 | 14.2 |

| R-53 | 323.85 | 11.13 | 17.5 |

| R-54 | 323.85 | 15.88 | 22.4 |

| R-55 | 342.9 | 28.58 | 36.6 |

| R-56 | 381 | 7.95 | 14.2 |

| R-57 | 381 | 11.13 | 17.5 |

| R-58 | 381 | 22.23 | 28.7 |

| R-59 | 396.88 | 7.95 | 14.2 |

| R-60 | 406.4 | 31.75 | 39.6 |

| R-61 | 419.1 | 11.13 | 17.5 |

| R-62 | 419.1 | 15.88 | 22.4 |

| R-63 | 419.1 | 25.4 | 33.3 |

| R-64 | 454.03 | 7.95 | 14.2 |

| R-65 | 469.9 | 11.13 | 17.5 |

| R-66 | 469.9 | 15.88 | 22.4 |

| R-67 | 469.9 | 28.58 | 36.6 |

| R-68 | 517.53 | 7.95 | 14.2 |

| R-69 | 533.4 | 11.13 | 17.5 |

| R-70 | 533.4 | 19.05 | 25.4 |

| R-71 | 533.4 | 28.58 | 36.6 |

| R-72 | 558.8 | 7.95 | 14.2 |

| R-73 | 584.2 | 12.7 | 19.1 |

| R-74 | 584.2 | 19.05 | 25.4 |

| R-75 | 584.2 | 31.75 | 39.6 |

| R-76 | 673.1 | 7.95 | 14.2 |

| R-77 | 692.15 | 15.88 | 22.4 |

| R-78 | 692.15 | 25.4 | 33.3 |

| R-79 | 692.15 | 34.93 | 44.5 |

| R-92 | 228.6 | 11.13 | 17.5 |

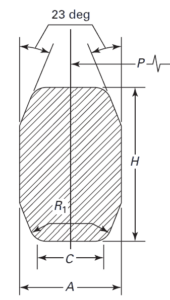

Octagonal Type Metal Gasket Dimensions

| R no | P-Pitch Dia | A-Width | H- Height Octagonal Ring | C- Width of Flat on Octagonal Ring | R1 – Radius Octagonal Ring |

|---|---|---|---|---|---|

| R-11 | 34.14 | 6.35 | 9.7 | 4.32 | 1.5 |

| R-12 | 39.7 | 7.95 | 12.7 | 5.23 | 1.5 |

| R-13 | 42.88 | 7.95 | 12.7 | 5.23 | 1.5 |

| R-14 | 44.45 | 7.95 | 12.7 | 5.23 | 1.5 |

| R-15 | 47.63 | 7.95 | 12.7 | 5.23 | 1.5 |

| R-16 | 50.8 | 7.95 | 12.7 | 5.23 | 1.5 |

| R-17 | 57.15 | 7.95 | 12.7 | 5.23 | 1.5 |

| R-18 | 60.33 | 7.95 | 12.7 | 5.23 | 1.5 |

| R-19 | 65.1 | 7.95 | 12.7 | 5.23 | 1.5 |

| R-20 | 68.28 | 7.95 | 12.7 | 5.23 | 1.5 |

| R-21 | 72.24 | 11.13 | 16 | 7.75 | 1.5 |

| R-22 | 82.55 | 7.95 | 12.7 | 5.23 | 1.5 |

| R-23 | 82.55 | 11.13 | 16 | 7.75 | 1.5 |

| R-24 | 95.25 | 11.13 | 16 | 7.75 | 1.5 |

| R-25 | 101.6 | 7.95 | 12.7 | 5.23 | 1.5 |

| R-26 | 101.6 | 11.13 | 16 | 7.75 | 1.5 |

| R-27 | 107.95 | 11.13 | 16 | 7.75 | 1.5 |

| R-28 | 111.13 | 12.7 | 17.5 | 8.66 | 1.5 |

| R-29 | 114.3 | 7.95 | 12.7 | 5.23 | 1.5 |

| R-30 | 117.48 | 11.13 | 16 | 7.75 | 1.5 |

| R-31 | 123.83 | 11.13 | 16 | 7.75 | 1.5 |

| R-32 | 127 | 12.7 | 17.5 | 8.66 | 1.5 |

| R-33 | 131.78 | 7.95 | 12.7 | 5.23 | 1.5 |

| R-34 | 131.78 | 11.13 | 16 | 7.75 | 1.5 |

| R-35 | 136.53 | 11.13 | 16 | 7.75 | 1.5 |

| R-36 | 149.23 | 7.95 | 12.7 | 5.23 | 1.5 |

| R-37 | 149.23 | 11.13 | 16 | 7.75 | 1.5 |

| R-38 | 157.18 | 15.88 | 20.6 | 10.49 | 1.5 |

| R-39 | 161.93 | 11.13 | 16 | 7.75 | 1.5 |

| R-40 | 171.45 | 7.95 | 12.7 | 5.23 | 1.5 |

| R-41 | 180.98 | 11.13 | 16 | 7.75 | 1.5 |

| R-42 | 190.5 | 19.05 | 23.9 | 12.32 | 1.5 |

| R-43 | 193.68 | 7.95 | 12.7 | 5.23 | 1.5 |

| R-44 | 193.68 | 11.13 | 16 | 7.75 | 1.5 |

| R-45 | 211.15 | 11.13 | 16 | 7.75 | 1.5 |

| R-46 | 211.15 | 12.7 | 17.5 | 8.66 | 1.5 |

| R-47 | 228.6 | 19.05 | 23.9 | 12.32 | 1.5 |

| R-48 | 247.65 | 7.95 | 12.7 | 5.23 | 1.5 |

| R-49 | 269.88 | 11.13 | 16 | 7.75 | 1.5 |

| R-50 | 269.88 | 15.88 | 20.6 | 10.49 | 1.5 |

| R-51 | 279.4 | 22.23 | 26.9 | 14.81 | 1.5 |

| R-52 | 304.8 | 7.95 | 12.7 | 5.23 | 1.5 |

| R-53 | 323.85 | 11.13 | 16 | 7.75 | 1.5 |

| R-54 | 323.85 | 15.88 | 20.6 | 10.49 | 1.5 |

| R-55 | 342.9 | 28.58 | 35.1 | 19.81 | 2.3 |

| R-56 | 381 | 7.95 | 12.7 | 5.23 | 1.5 |

| R-57 | 381 | 11.13 | 16 | 7.75 | 1.5 |

| R-58 | 381 | 22.23 | 26.9 | 14.81 | 1.5 |

| R-59 | 396.88 | 7.95 | 12.7 | 5.23 | 1.5 |

| R-60 | 406.4 | 31.75 | 38.1 | 22.33 | 2.3 |

| R-61 | 419.1 | 11.13 | 16 | 7.75 | 1.5 |

| R-62 | 419.1 | 15.88 | 20.6 | 10.49 | 1.5 |

| R-63 | 419.1 | 25.4 | 31.8 | 17.3 | 2.3 |

| R-64 | 454.03 | 7.95 | 12.7 | 5.23 | 1.5 |

| R-65 | 469.9 | 11.13 | 16 | 7.75 | 1.5 |

| R-66 | 469.9 | 15.88 | 20.6 | 10.49 | 1.5 |

| R-67 | 469.9 | 28.58 | 35.1 | 19.81 | 2.3 |

| R-68 | 517.53 | 7.95 | 12.7 | 5.23 | 1.5 |

| R-69 | 533.4 | 11.13 | 16 | 7.75 | 1.5 |

| R-70 | 533.4 | 19.05 | 23.9 | 12.32 | 1.5 |

| R-71 | 533.4 | 28.58 | 35.1 | 19.81 | 2.3 |

| R-72 | 558.8 | 7.95 | 12.7 | 5.23 | 1.5 |

| R-73 | 584.2 | 12.7 | 17.5 | 8.66 | 1.5 |

| R-74 | 584.2 | 19.05 | 23.9 | 12.32 | 1.5 |

| R-75 | 584.2 | 31.75 | 38.1 | 22.33 | 2.3 |

| R-76 | 673.1 | 7.95 | 12.7 | 5.23 | 1.5 |

| R-77 | 692.15 | 15.88 | 20.6 | 10.49 | 1.5 |

| R-78 | 692.15 | 25.4 | 31.8 | 17.3 | 2.3 |

| R-79 | 692.15 | 34.93 | 41.4 | 24.82 | 2.3 |

| R-80 | 615.95 | 7.95 | 12.7 | 5.23 | 1.5 |

| R-81 | 635 | 14.3 | 19.1 | 9.58 | 1.5 |

| R-82 | 57.15 | 11.13 | 16 | 7.75 | 1.5 |

| R-84 | 63.5 | 11.13 | 16 | 7.75 | 1.5 |

| R-85 | 79.38 | 12.7 | 17.5 | 8.66 | 1.5 |

| R-86 | 90.5 | 15.88 | 20.6 | 10.49 | 1.5 |

| R-87 | 100.03 | 15.88 | 20.6 | 10.49 | 1.5 |

| R-88 | 123.83 | 19.05 | 23.9 | 12.32 | 1.5 |

| R-89 | 114.3 | 19.05 | 23.9 | 12.32 | 1.5 |

| R-90 | 155.58 | 22.23 | 26.9 | 14.81 | 1.5 |

| R-91 | 260.35 | 31.75 | 38.1 | 22.33 | 2.3 |

| R-92 | 228.6 | 11.13 | 16 | 7.75 | 1.5 |

| R-93 | 749.3 | 19.05 | 23.9 | 12.32 | 1.5 |

| R-94 | 800.1 | 19.05 | 23.9 | 12.32 | 1.5 |

| R-95 | 857.25 | 19.05 | 23.9 | 12.32 | 1.5 |

| R-96 | 914.4 | 22.23 | 26.9 | 14.81 | 1.5 |

| R-97 | 965.2 | 22.23 | 26.9 | 14.81 | 1.5 |

| R-98 | 1022.35 | 22.23 | 26.9 | 14.81 | 1.5 |

| R-99 | 234.95 | 11.13 | 16 | 7.75 | 1.5 |

| R-100 | 749.3 | 28.58 | 35.1 | 19.81 | 2.3 |

| R-101 | 800.1 | 31.75 | 38.1 | 22.33 | 2.3 |

| R-102 | 857.25 | 31.75 | 38.1 | 22.33 | 2.3 |

| R-103 | 914.4 | 31.75 | 38.1 | 22.33 | 2.3 |

| R-104 | 965.2 | 34.93 | 41.4 | 24.82 | 2.3 |

| R-105 | 1022.35 | 34.93 | 41.4 | 24.82 | 2.3 |

Tolerances in millimeters

- Width of ring +/- 0.20 mm

- Height of ring +1.3 mm to -0.5 mm

- Width of end flat on octagonal ring +/- 0.20 mm

- Average pith diameter of ring +/- 0.18 mm

- Corner radius on octagonal ring +/- 0.50 mm

- Angle +/- 1/2 degree

- Angle +/- 1/2 degree

Are You Piping Components Master?