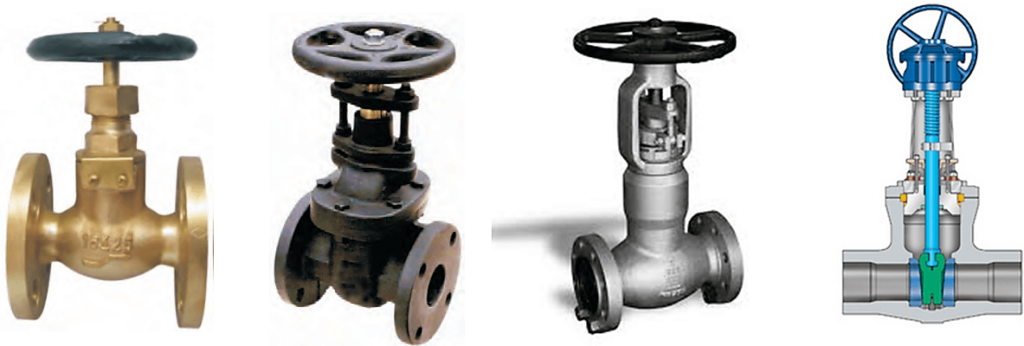

Gate valves are essential components in various process industries, providing efficient control over the flow of fluids and gases. Among the different types of industrial valves, some of the most commonly used variants are covered here. In this article, I have explained different construction, applications, and the advantages they offer.

Table of Contents

What is Gate Valve?

A gate valve can be defined as a type of valve that uses a gate or wedge-type disk, which moves perpendicular to flow to start or stop the fluid flow in piping.

It is the most common type of that used in any process plant. It is a linear motion valve used to start or stop fluid flow. In service, the valve position is either fully open or fully closed gate.

When the gate valve is open fully, the disk is completely removed from the flow. Therefore virtually has no obstruction to flow. Due to this, very little pressure drops across the valve when fluid passes through it.

To achieve proper sealing, 360° surface contact is required between the gate and seats when the valve is fully closed.

It should not be used for regulation or throttling of flow by a partially open gate because accurate control is not possible. The high velocity of the flow in the partially open gate valve may cause erosion of the disc and seating surfaces and also creates vibration and noise.

Unlock New Skills with Our Best Selling Online Courses

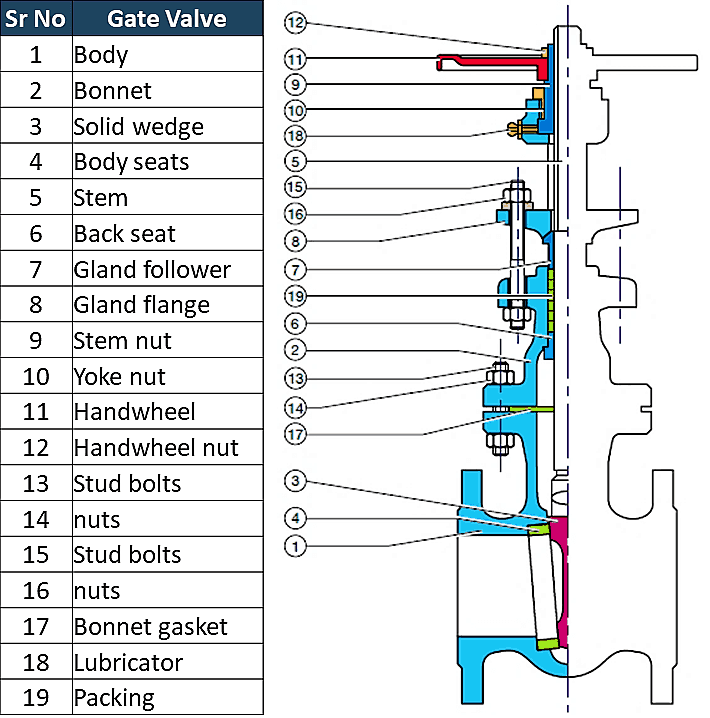

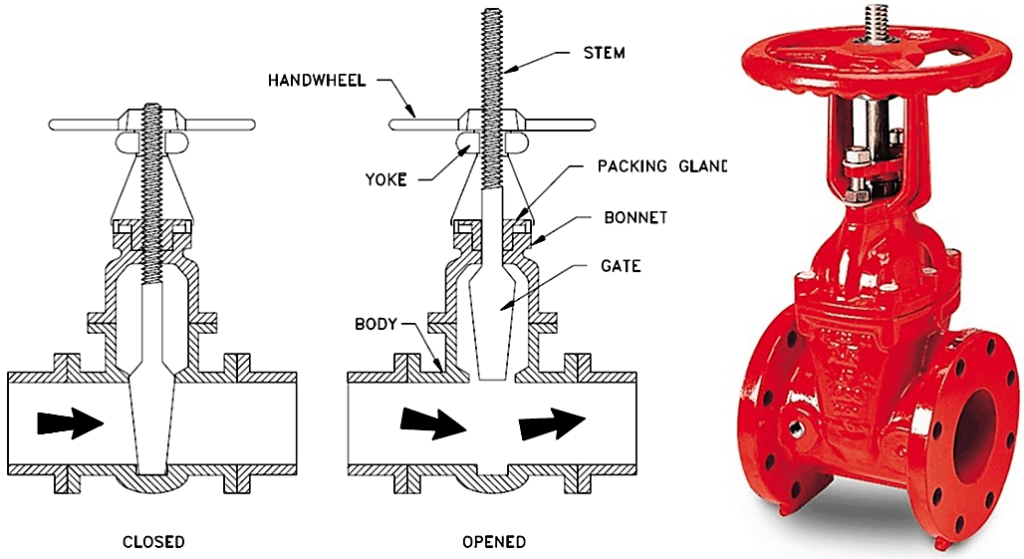

Gate Valve Construction – Body and Valve Trim Parts

Here you can see the main parts of the typical gate valve. The disk of a gate valve is also known as a wedge. Gate valves consist of many parts as listed below. You can learn about each of these parts by visiting this article – Valve Trim and Parts Including API Trim Charts

- Body

- Bonnet

- Solid Wedge

- Body Seat

- Stem

- Back Seat

- Gland Follower

- Gland Flange

- Stem Nut

- Yoke Nut

- Handwheel

- Handwheel Nut

- Stud and Bolts

- Nuts

- Bonnet Gasket

- Lubricator

- Gland Packing

Image- Trouvay & Cauvin

Types of Gate Valves

Gate Valves are typically classified into three ways.

- Types of Disk

- Solid taper wedge

- Flexible wedge

- Split wedge or Parallel disks Valve

- Types of Body Bonnet Joint

- Screwed Bonnet

- Bolted-Bonnet

- Welded-Bonnet

- Pressure-Seal Bonnet

- Types of Stem Movement

- Rising Stem or OS & Y Type (Outside Stem and Screw Type)

- Non-rising Stem type

Valve Quiz – Test yourself, Take This Quiz

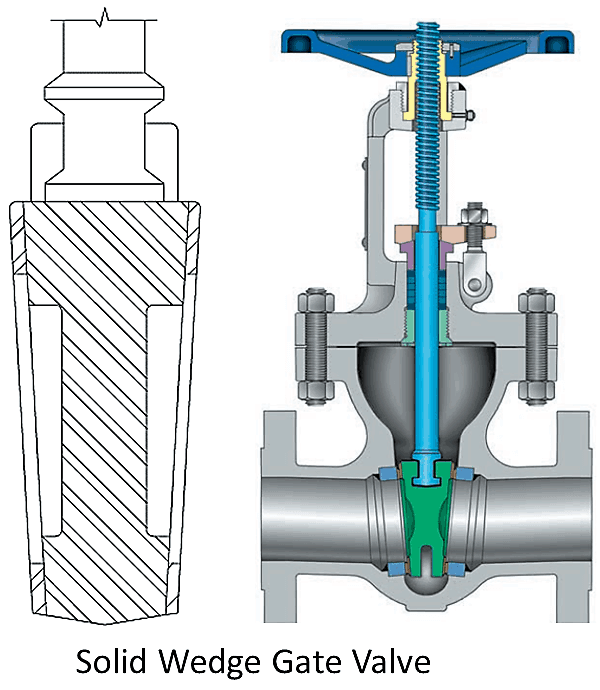

Solid Wedge Shaped Gate Valve

A solid wedge is the most common & widely used disk type because of its simplicity and strength. A valve with this type of disk may be installed in any position, and it is suitable for almost all fluids. It can be used in turbulent flow also.

However, it does not compensate for changes in seat alignment due to pipe loads or thermal expansion. So, this type of disk design is most susceptible to leakage. It is subjected to thermal locking if used in high-temperature service.

Thermal locking is a phenomenon in which a valve gate is stuck between the seats due to the expansion of the metal. Solid-wedge gate valves are generally used in moderate to lower pressure-temperature applications.

It is a typical gate valve with no obstruction in the flow path when the valve is fully opened. The gate, fixed to the valve stem, is either threaded into the gate or connected using other mechanisms. When the valve is closed, the gate is lowered to block the flow of fluid, and when opened, it allows the fluid to pass freely through the valve.

Image – Velan is a global leader in valve supply. Check their website for more product offerings.

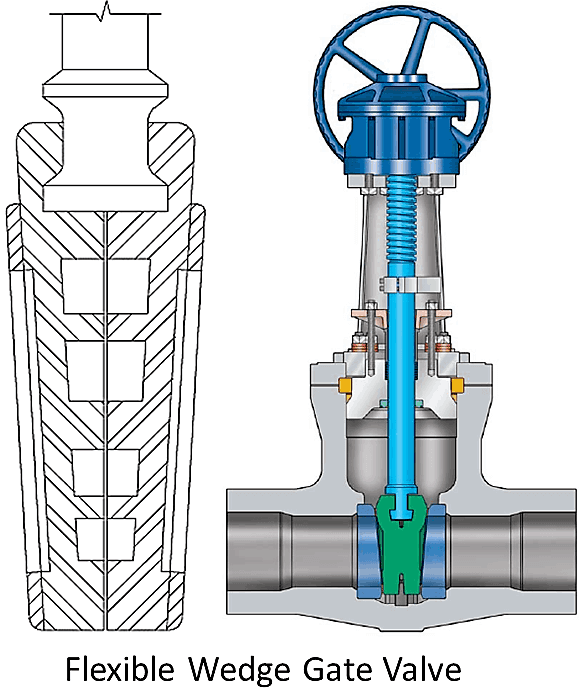

Flexible Wedge Gate Valve

The flexible wedge is a one-piece solid disk with a cut around the perimeter. These cuts vary in size, shape, and depth. A shallow, narrow cut on the wedge perimeter gives less flexibility but retains strength. A cast-in recess or deeper and wider cut on the wedge perimeter gives more flexibility but compromises the strength.

This design improves seat alignment and offers better leak tightness. It also improved performance in situations where thermal binding possible. These types are used in steam systems.

Thermal expansion of the steam line sometime causes distortion of valve bodies which may lead to thermal blinding. The flexible gate allows the gate to flex as the valve seat compresses due to the thermal expansion of the steam pipeline and prevents thermal blinding.

The disadvantage of flexible gates is that line fluid tends to collect in the disk. These may result in corrosion and ultimately weaken the disk.

Unlock New Skills with Our Best Selling Online Courses

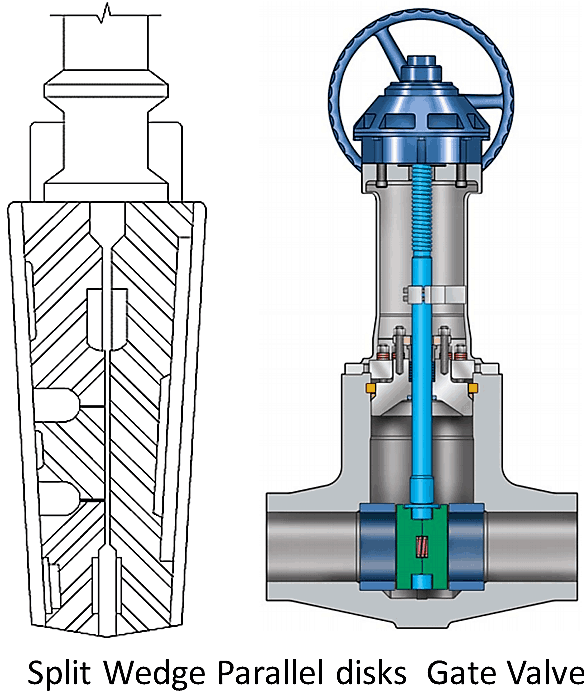

Split wedge or Parallel disks Gate Valve

A split wedge Disk consists of two solid pieces and holds together with the help of a special mechanism. You can see the same in the images. In case one-half of the disk is out of alignment, the disk is free to adjust itself to the seating surface. The split disk can be in a wedge shape or a parallel disk type.

Parallel disks are spring-loaded, so they are always in contact with seats and give bi-directional sealing. The split wedge is suitable for handling noncondensing gasses and liquids at normal and high temperatures.

Freedom of movement of the disk prevents thermal binding even though the valve may have been closed when a line is cold. This means when a line gets heated by fluid and expands, it does not create thermal blinding.

Types of gate valves based on body, bonnet connection

1st is screwed bonnet: This is the simplest design available and it is used for inexpensive valves.

2nd is bolted-bonnet: This is the most popular design and is used in a large number of gate valves. This requires a gasket to seal the joint between the body and the bonnet.

3rd is Welded-Bonnet: This is a popular design where disassembly is not required. They are lighter in weight than their bolted-bonnet counterparts.

4th one is Pressure-Seal Bonnet: This type is used extensively for high-pressure high-temperature applications. The higher the body cavity pressure, the greater the force on the gasket in a pressure-seal valve.

Types of Valves Based on Valve Stem Function

OS & Y Gate Valve or Rising Stem (Outside Stem and Screw Type)

For a rising stem valve, the stem will go up while opening and move down when you close the valve. You can see it in the image. In the inside screw design, the threaded portion of the stem is in contact with the flow medium, and when you open the valve, the handwheel rises with the stem.

Whereas in the case of outside screw design, the only smooth portion is exposed to the flow medium and the stem will rise above the handwheel. This type of valve is also known as OS & Y valve. OS & Y means outside stem and York.

The stem movement will give you a visual indication of valve positions.

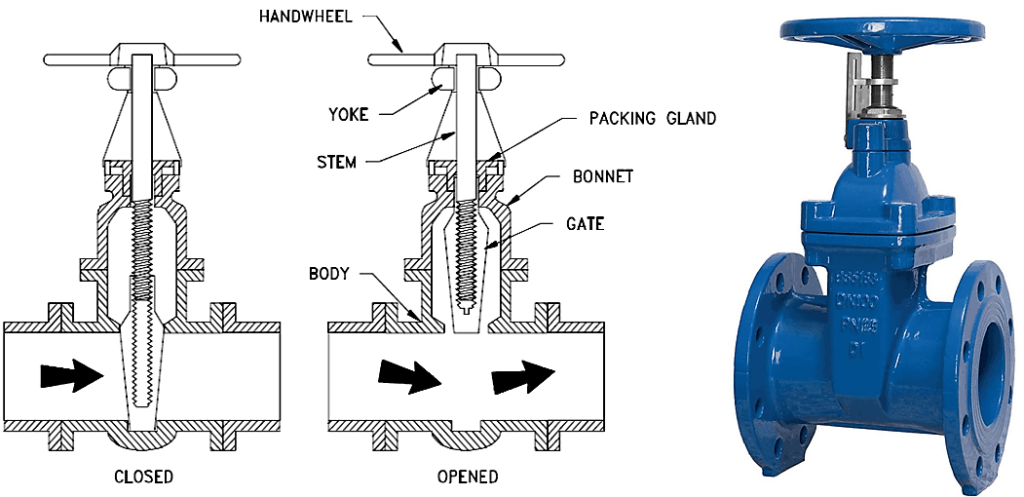

Non-rising Stem Gate Valve or Insider Screw Valve

Unlock New Skills with Our Best Selling Online Courses

There is no upward movement of the stem in a non-rising stem type. The valve disk is threaded internally. This design slide gate along the stem like a nut when the stem is rotated. You can see the image. This type of valve exposes stem threads to the flow medium when the valve is closed.

Therefore, this design is used where space is limited to allow linear stem movement, and the flow medium does not cause erosion, corrosion, or wear and tear to stem material. This type of valve is also known as an insider screw valve.

Knife Gate Valve

A knife gate valve is used in applications where a sharp-edged gate is used to cut through thick fluids, slurries, or powders. This valve is commonly found in the mining, chemical, pulp, and paper industries.

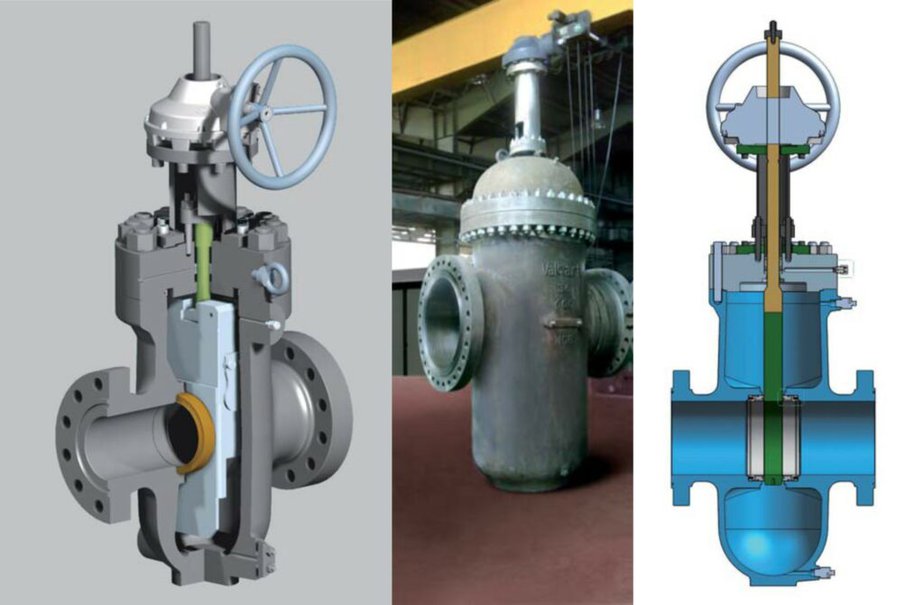

Through-Conduit Gate Valve

Through-conduit gate valves are designed with gates that are fully enclosed within the valve body. This type of valve is commonly used in applications where a full-bore opening is required to allow the passage of pigging devices.

Image Source – www.valbart.com

Gate Valve Used and Applications

- Gate valves are often used in almost all fluid services such as air, fuel gas, feedwater, steam, lube oil, hydrocarbon, and almost any services.

- Some special type is used in slurry and powder product also, such as knife gate valve.

- Metal seated gate valves are commonly used in high temperature applications.

What is the advantage of gate valve?

- The gate valve is designed to provide good shutoff

- The gate valve has no obstruction so the pressure in the valve doesn’t drop during operation and the loss is very minimal.

- Most of the gate valves can be used as bi-directional

- They are suitable for high pressure and temperature application and require less maintenance

What is the disadvantage of gate valve?

- It cannot be used to control the flow like globe valve and butterfly valve.

- It is slow in operation. Opening and closing take time which is good also as it reduces the chance of hammering.

- When partially open, it creates vibration and noise.

- Repairs, such as lapping and grinding of seats are more difficult due to limited access.

These valves are versatile devices that find applications in a wide range of industries. The use of a specific type depends on the requirements of the application, the fluid or gas being controlled, and the operating conditions.

Click here to learn about Other Types of Valve

Unlock New Skills with Our Best Selling Online Courses