In this article, you will learn about Spiral Wound Gasket. You will learn the following;

- Definition of the SWG

- Components of gasket

- Marking of gasket

- Color Coding of spiral wound gasket

- Dimensions of the SWG gasket

Knowing color coding is extremely important if you are working in the field, as a small mistake in selecting the wrong gasket can result in a loss of time and money, which no one likes. Watch the video until the end to avoid reading this article.

What is Spiral Wound Gasket?

Why did we call it SWG? SWG is a short form of Spiral Wound Gasket.

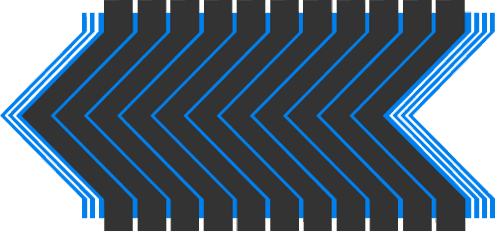

These gaskets are fabricated from thin metal strips sandwiched between layers of non-metallic filler. SWG has alternative spiral layers of thin metal sheet and filler material, as shown in the image. Here in the cross-section, the blue layers are of metal, and the black layers are of filler material. As these layers are wounded in continuous spiral forms, these types of gaskets are known as spiral wound gaskets.

Image Source: apollon-indutec

These gaskets are extremely popular due to the wide variety of available styles and sizes.

SWG can be fabricated of any metal available in thin strips and welded; therefore, they can be used against virtually any corrosive medium.

They can be used over the complete temperature range from cryogenic to approximately 1093ºC. This type of gasket can be used in all pressures from vacuum to the standard 2500 pressure class flange ratings.

Relatively low-density Spiral wound gaskets are used in vacuum service, whereas extremely high-density Spiral wound gaskets are used in high-pressure service. The density of the gasket is nothing but a number of layers of filler and metal strips in the given width of the gasket.

Components of Spiral Gasket

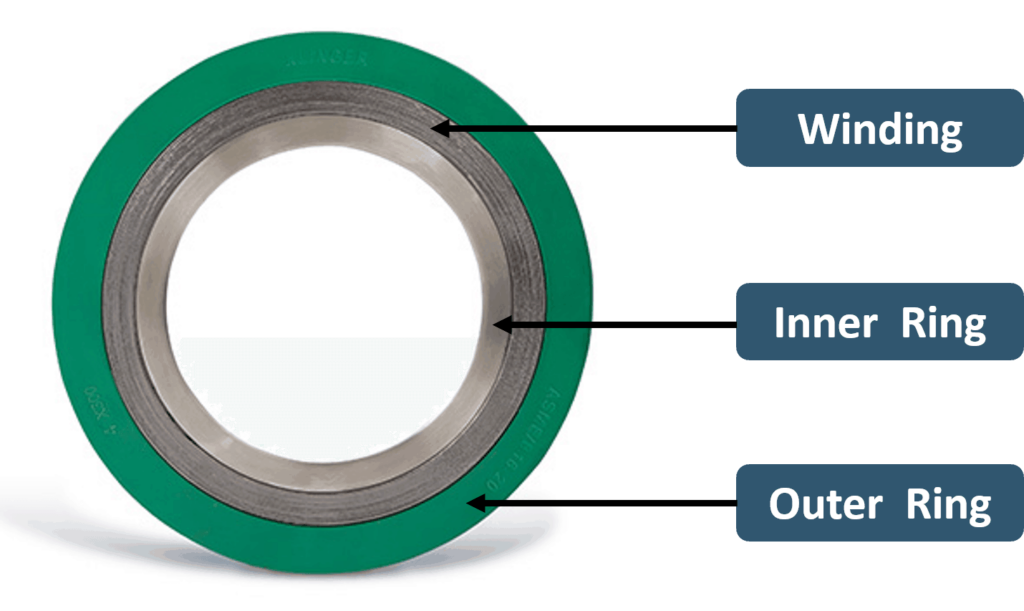

There are three components in the spiral wound gasket.

- Outer Ring

- Winding Material (Filler & Metal Strip)

- Inner Ring

Gasket Quiz – Test yourself, Take This Quiz

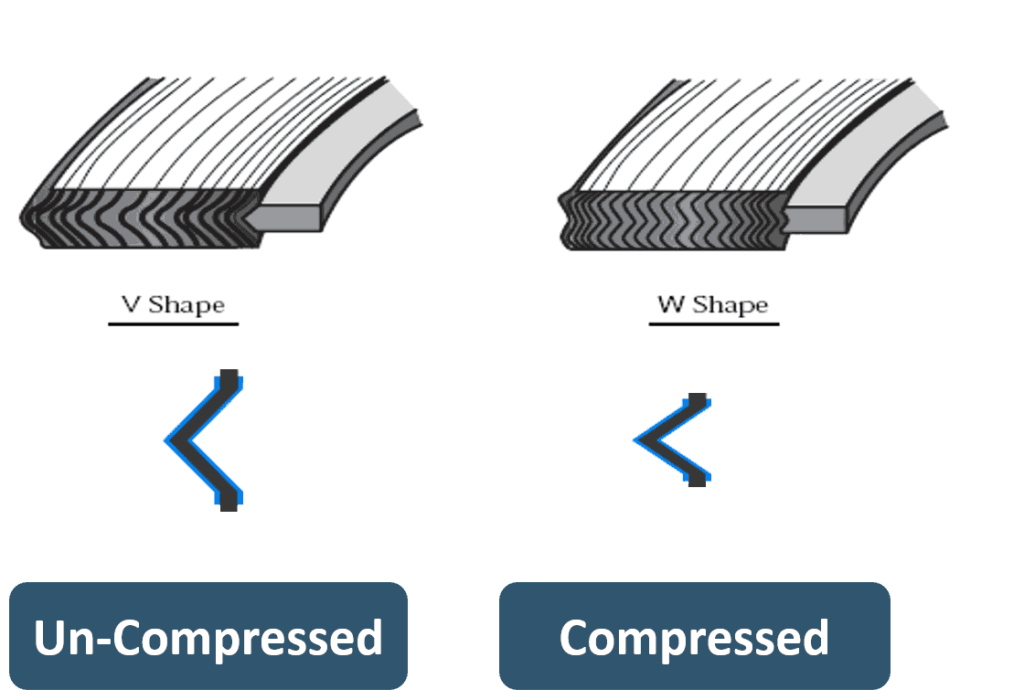

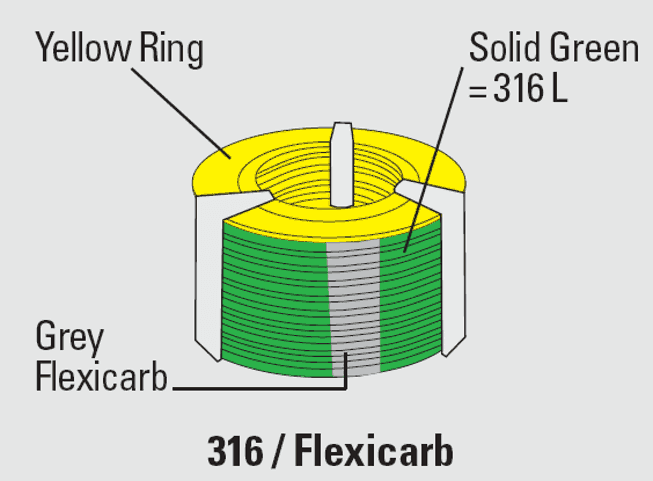

You can see in the image a spiral wound gasket. As said, the winding is an alternative layer of filler material and winding material. Winding can be a V-type or W-type. These V or W shape, under pressure it presses against the flange face and compresses the filling material to provide leak-proof joining.

The filler material can be graphite, PTFE, ceramic, or other material, depending on the service of the fluid. Spot welding normally secures the inner and outer ends of the strip that wraps the filler material; the gasket is contained loosely in an outer backing ring.

For applications involving raised face flanges, the spiral wound gasket is supplied with an outer ring made from Carbon steel, Stainless steel, or other materials such as Monel or Nickel. The outer ring provides the centering capability of the gasket as well as the blow-out resistance of the windings and acts as a compression stop.

Many SW gaskets for critical applications also include an inner guide ring, which gives the gasket a greater resistance to thermal shock, and in the case of vacuum service, it prevents the filler material from being sucked inside the pipe. Inner rings should be used with spiral wound gaskets on male-and-female flanges, such as those found in heat-exchanger, shell, channel, and cover-flange joints.

Spiral wound ring gaskets are also used in tongue-and-groove flanges. When used in this flange type, there will be no inner and outer metal rings as the gasket fit inside the groove.

Gasket Marking

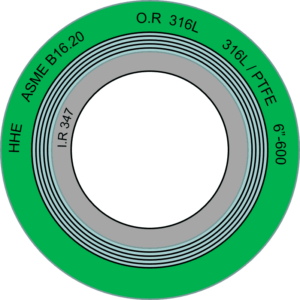

Knowing the marking of a gasket is very important while selecting a proper gasket. Each gasket shall be marked with

- Manufacturer logo

- Manufacturing standard

- Size and Pressure Class

- Type of Filler Material

- Type of Winding Material

- Inner and Outer Ring material

You can see the sample marking in the image.

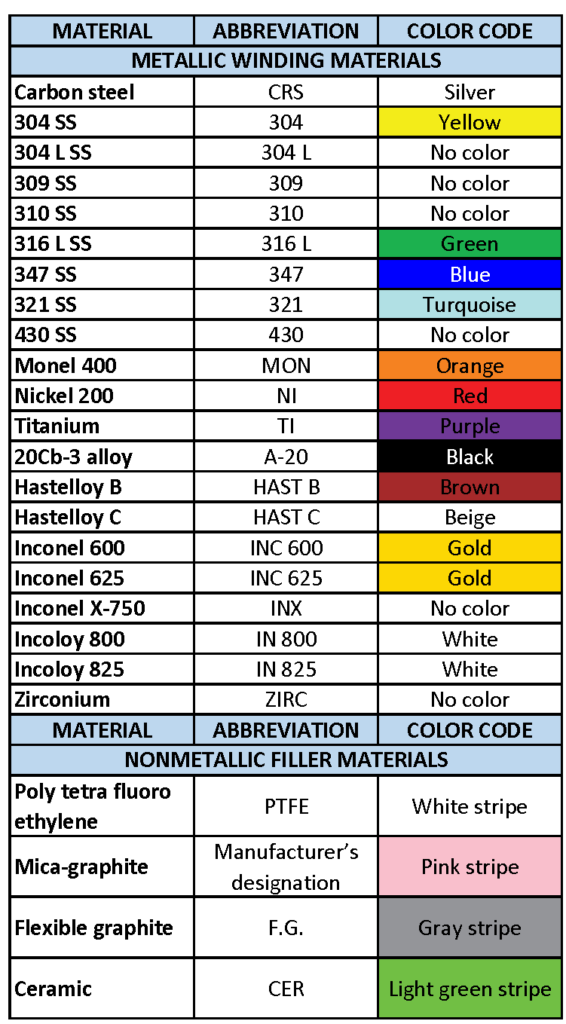

Color Coding of Spiral Wound Gasket

Spiral Wound Gaskets are painted in accordance with ASME B16.20 for easy identification. Refer to the image given below for the standard marking on gaskets.

Image Source: Flexitallic Visit for more info on SWG

The image below shows the color codes for winding and filler materials.

Are You Piping Components Master?