What is Weldolet?

Weldolet is a type of self-reinforced branch fitting developed by a Company called Bonney Forge. It is used when branch connections are required in size where reducing tees are not available and/or when the branch connections are smaller than header size or when tee cannot be accommodated in the piping header, weldolets are used.

It comes in full size or reducing size. Full size is when you take a branch of the same size as run pipe size, for example, 3 inches to 3 inches. And reducing size is when branch size is less than run pipe size. For example, 3 inches to 1 inch. Weldolet’s end is suited for the butt welding connection.

Weldolets are available in Standard Weight, Extra Strong, and Double Extra Strong (Schedule 160).

Weldolet® is a Registered Trademark of Bonney Forge.

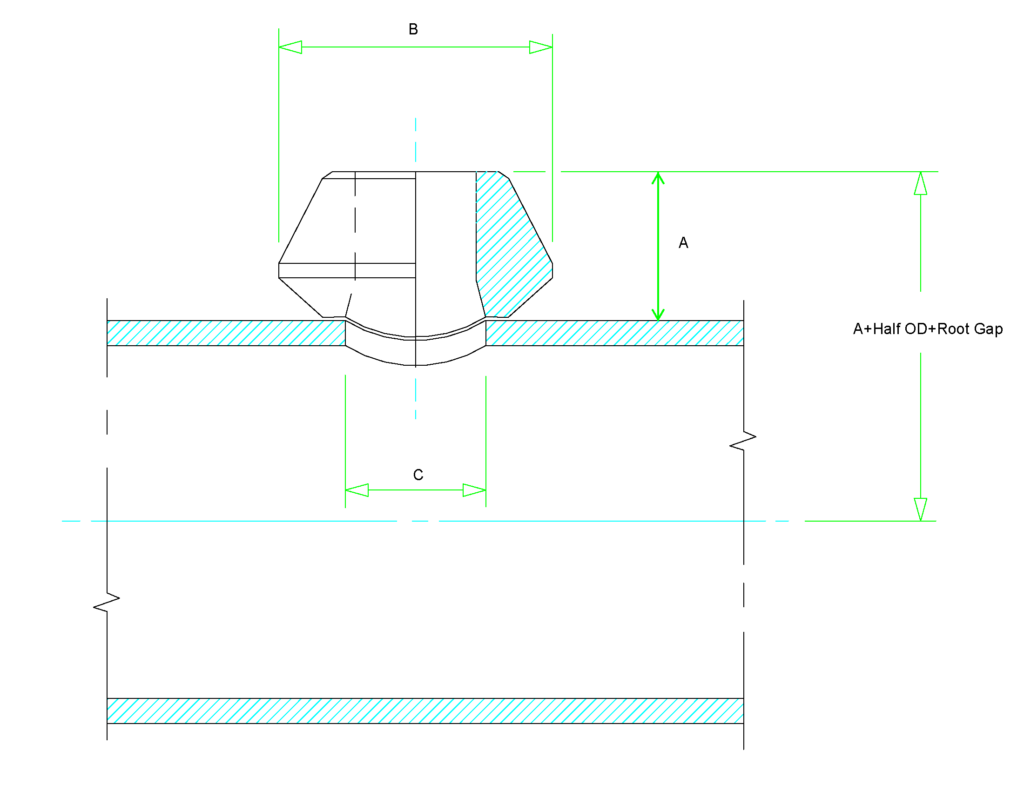

Weldolet Dimensions

During the Dimensional inspection of weldolets, you should check for

- Outer & Inner Diameter of body

- Length of the Hub

- End preparation (Bevel angle)

Olets are designed for specific conditions based on Process piping Code ASME B31.3; hence, Dimension is also specified by the designer. However, MSS-SP-97 provides dimension requirements for standard 90° self-reinforced branch connection with butt, socket, and threaded end types.

Flange and Olet Quiz – Test yourself, Take This Quiz

Unlock New Skills with Our Best Selling Online Courses

Weldolet Dimensions Chart

Schedule STD Weldolet Dimensions

| Size | Size in mm | Height A | OD -B | Hole Dia C | Weight in KG |

|---|---|---|---|---|---|

| 1/4 | 8 | 14.3 | 25.4 | 15.9 | 0.04 |

| 3/8 | 10 | 19.05 | 31.75 | 19.05 | 0.07 |

| 1/2 | 15 | 19.05 | 34.93 | 23.81 | 0.08 |

| 3/4 | 20 | 22.23 | 44.45 | 30.16 | 0.11 |

| 1 | 25 | 26.99 | 53.98 | 36.51 | 0.23 |

| 1 1/4 | 32 | 31.75 | 65.09 | 44.45 | 0.36 |

| 1 1/2 | 40 | 33.34 | 73.03 | 50.8 | 0.45 |

| 2 | 50 | 38.1 | 88.9 | 65.09 | 0.79 |

| 2 1/2 | 65 | 41.28 | 103.19 | 76.2 | 1.13 |

| 3 | 80 | 44.45 | 122.24 | 93.66 | 1.81 |

| 3 1/2 | 90 | 47.63 | 142.88 | 112.71 | 2.5 |

| 4 | 100 | 50.8 | 152.4 | 120.65 | 2.86 |

| 5 | 130 | 57.15 | 179.3 | 141.29 | 4.65 |

| 6 | 150 | 60.33 | 215.9 | 169.86 | 6.44 |

| 8 | 200 | 69.85 | 263.53 | 220.66 | 10.66 |

| 10 | 250 | 77.79 | 322.26 | 274.64 | 17.69 |

| 12 | 300 | 85.73 | 377.83 | 325.44 | 26.76 |

| 14 | 350 | 88.9 | 409.58 | 357.19 | 29.94 |

| 16 | 400 | 93.6 | 463.55 | 407.99 | 34.02 |

| 18 | 450 | 96.84 | 520.7 | 458.79 | 44 |

| 20 | 500 | 101.6 | 571.5 | 508 | 53.52 |

| 24 | 600 | 144.5 | 717.5 | 609.6 | 101 |

| 26 | 650 | 155.6 | 778 | 660.4 | 120 |

| 30 | 750 | 174.6 | 893.6 | 762 | 190 |

| 36 | 900 | 206.4 | 1070 | 914.4 | 310 |

| 40 | 1000 | 225.4 | 1187.6 | 1016 | 435 |

| 42 | 1050 | 235 | 1244.6 | 1066.8 | 540 |

| 48 | 1200 | 241.3 | 1404 | 1219.2 | 750 |

Schedule XS Weldolet Dimensions

| Size | Size in mm | Height – A | OD – B | Hole Dia – C | Weight in KG |

|---|---|---|---|---|---|

| 1/4 | 8 | N/A | 25.4 | 15.88 | 0.05 |

| 3/8 | 10 | N/A | 31.75 | 19.05 | 0.07 |

| 1/2 | 15 | 19.05 | 34.93 | 23.81 | 0.09 |

| 3/4 | 20 | 22.23 | 44.45 | 30.16 | 0.14 |

| 1 | 25 | 26.99 | 53.98 | 36.51 | 0.21 |

| 1 1/4 | 32 | 31.75 | 65.09 | 44.45 | 0.41 |

| 1 1/2 | 40 | 33.34 | 73.03 | 50.8 | 0.5 |

| 2 | 50 | 38.1 | 88.9 | 65.09 | 0.79 |

| 2 1/2 | 65 | 41.28 | 103.19 | 76.2 | 1.18 |

| 3 | 80 | 44.45 | 122.24 | 93.66 | 1.86 |

| 3 1/2 | 90 | 47.63 | 136.53 | 112.71 | 2.54 |

| 4 | 100 | 50.8 | 152.4 | 120.65 | 2.9 |

| 6 | 150 | 77.79 | 225.43 | 169.86 | 10.43 |

| 8 | 200 | 98.43 | 292.1 | 220.66 | 16.78 |

| 10 | 250 | 93.66 | 323.85 | 265.11 | 20.87 |

| 12 | 300 | 103.1 | 379.41 | 317.5 | 27.67 |

| 14 | 350 | 100.01 | 431.8 | 350.84 | 31.75 |

| 16 | 400 | 106.36 | 466.73 | 403.23 | 46.27 |

| 18 | 450 | 111.13 | 523.88 | 455.61 | 58.97 |

| 20 | 500 | 119.06 | 582.61 | 509.59 | 71.67 |

| 24 | 600 | 152.4 | 722.2 | 609.6 | 142 |

| 26 | 650 | 165.1 | 782.6 | 660.4 | 168 |

| 30 | 750 | 181 | 896.8 | 762 | 218 |

| 36 | 900 | 212.7 | 1074.4 | 914.4 | 404 |

| 40 | 1000 | 235 | 1194 | 1016 | 582 |

| 42 | 1050 | 244.5 | 1250.8 | 1066.8 | 590 |

| 48 | 1200 | 273 | 1425.6 | 1219.2 | 910 |

Schedule XXS Weldolet Dimensions

| Size | Size in mm | Height – A | OD – B | Hole Dia – C | Weight in KG |

|---|---|---|---|---|---|

| 1/2 | 15 | 28.58 | 34.93 | 14.29 | 0.11 |

| 3/4 | 20 | 31.75 | 44.45 | 19.05 | 0.32 |

| 1 | 25 | 38.1 | 50.8 | 25.4 | 0.38 |

| 1 1/4 | 32 | 44.45 | 61.91 | 33.34 | 0.57 |

| 1 1/2 | 40 | 50.8 | 69.85 | 38.1 | 0.79 |

| 2 | 50 | 55.56 | 80.96 | 42.86 | 0.97 |

| 2 1/2 | 65 | 61.91 | 96.84 | 53.98 | 1.53 |

| 3 | 80 | 73.03 | 120.65 | 73.03 | 2.87 |

| 4 | 100 | 84.14 | 152.4 | 98.43 | 4.76 |

| 5 | 130 | 93.66 | 187.33 | 122.24 | 6.46 |

| 6 | 150 | 104.78 | 220.66 | 146.05 | 12.7 |

| 8 | 200 | 111.12 | 284.16 | 173.04 | 20.41 |

| 10 | 250 | 125.41 | 312.74 | 215.9 | 38.56 |

Schedule 160 Weldolet Dimensions

| Size | Size in mm | Height – A | OD – B | Hole Dia – C | Weight in KG |

|---|---|---|---|---|---|

| 1/2 | 15 | 28.58 | 34.93 | 14.29 | 0.11 |

| 3/4 | 20 | 31.75 | 44.45 | 19.05 | 0.32 |

| 1 | 25 | 38.1 | 50.8 | 25.4 | 0.38 |

| 1 1/4 | 32 | 44.45 | 61.91 | 33.34 | 0.57 |

| 1 1/2 | 40 | 50.8 | 69.85 | 38.1 | 0.79 |

| 2 | 50 | 55.56 | 80.96 | 42.86 | 0.97 |

| 2 1/2 | 65 | 61.91 | 96.84 | 53.98 | 1.53 |

| 3 | 80 | 73.03 | 120.65 | 73.03 | 2.87 |

| 4 | 100 | 84.14 | 152.4 | 98.43 | 4.76 |

| 5 | 130 | 93.66 | 187.33 | 122.24 | 6.46 |

| 6 | 150 | 104.78 | 220.66 | 146.05 | 12.7 |

| 8 | 200 | 111.12 | 284.16 | 173.04 | 20.41 |

| 10 | 250 | 125.41 | 312.74 | 215.9 | 38.56 |

Are You Piping Components Master?