In this article, I am going to talk about Pipe Rack. Pipe Racks are also known as pipe bridges, pipe ways, and pipeline corridors. In process plants such as refinery, petrochemical plant, or other facilities such as chemical and power plant, the movement of fluids are critical for the proper function of interconnected equipment and units.

Proper arrangements of these interconnected pipelines are necessary to reduce capital cost and increase plant efficiency to maximize plant profit.

What is a Pipe Rack?

Pipe racks are elevated steel or concrete structures designed to support pipes, electrical and instrument cable trays. Sometimes it supports mechanical equipment, vessels, and valve access platforms also.

The pipe rack supports all main process lines that connect equipment such as pumps, storage tanks, static vessels, and columns. It also connects various relief and blowdown headers. All lines leaving and entering the plant, utility supplying lines such as steam, air, cooling water, inert gas, etc., are routed through a pipeline corridor.

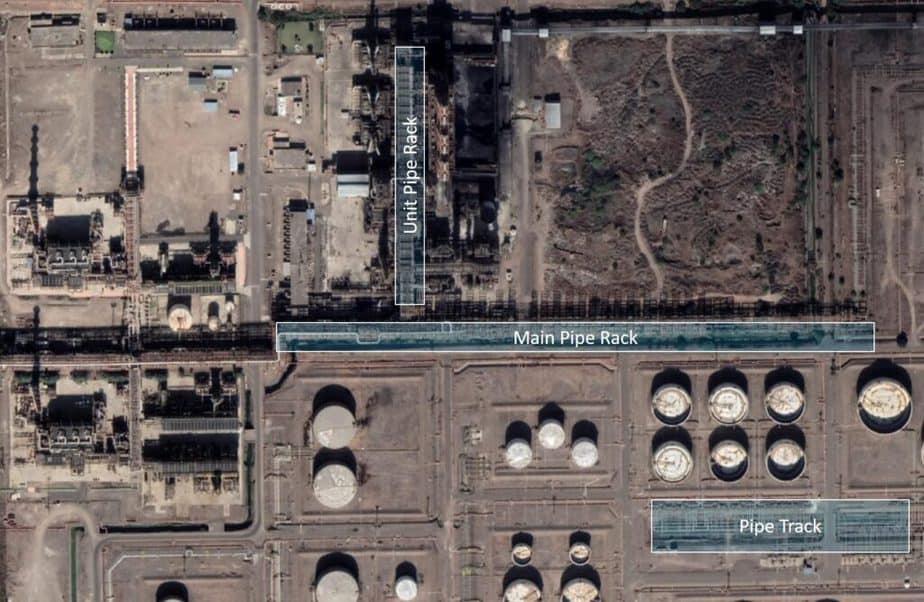

In any Oil and Gas processing facility, the petrochemical facility typically will have a “Main Pipe Rack(s),” which helps transfer material between equipment and storage or utility areas. Unit pipe racks are located within the unit and connect the equipment of the unit.

Refer to the image given here; the main pipe rack and unit pipe rack are shown. I have also shown Pipe Track. Do you know what is the difference between them?

Pipe tracks are grounded pipe support (Sleeper Supported), whereas pipe racks are elevated steel or concrete structures. Refer to this image to see the difference.

Pipe FIttings Quiz – Test yourself, Take This Quiz

Unlock New Skills with Our Best Selling Online Courses

Pipe Rack Types

In the process plant, you can see either of the following types of racks to support piping.

- Steel Structure

- RCC / Pre-cast

In the image here, you can see RCC types. The choice between them depends on cost, schedule, and availability of material and labor.

RCC racks are erected at the site, so it is time-consuming job due to the curing time of concrete. In concrete racks, the reinforcement is provided by the tensile strength of steel bars, and Cement provides compression strength. Nowadays, pre-cast beams and columns are used to construct concrete racks at the site. This will save site construction time and cost. Insert plates are used in columns and beams to weld steel members on them.

Steel racks are made using Beams, Channels, and Angles. It is mostly shop fabricated and either bolted or welded at the site. This will make installation very fast. However, these racks required parodic maintenance, such as painting due to corrosion.

Components of Pipe Rack

Frames

Piperacks are moment-resisting frames in the transverse and longitudinal direction. You can see the continuous beam struts on each side. Proper spacing is provided in the multi-level Piperack between the levels to facilitate any operation and maintenance work.

Vertical bracing in the longitudinal direction is provided to carry the longitudinal forces, transmitted through the beam struts, to the foundation. In the image here, you can see the typical multi-level Piperack.

Transverse and Longitudinal Beam

Transverse and Longitudinal Beams are designed to resist all forces, moments, and shears produced by the load combinations.

Column

Columns are designed to resist all loads, moments, and shears produced by the load combinations. It carries all primary loads.

Vertical Bracing

Vertical bracings are used to transmit the longitudinal forces from the beam struts to the foundations. K-bracing with equidistant between two expansion joints is used for this purpose. In the next article, I will explain to you about pipe rack design criteria.

In the next article, I will explain to you about pipe rack design criteria.

Co-Author with Mr. Nirmal Surendran Menon

Are You Piping Components Master?