Welcome to Hardhatengineer.com. I am Varun Patel. In this video, you will learn about the most common questions regarding gasket that you may face during the interview.

You will learn about these questions;

- How many types of gaskets are used in piping?

- What is the most commonly used gasket material for temporary piping?

- Which is the most commonly used gasket type for process piping?

- Which type of gasket is used for high-pressure piping?

- What are the criteria for the selection of Gasket?

So please watch this video till the end. And don’t forget to subscribe to my channel; that way, you will get regular updates on a new videos. You can subscribe right now by just clicking subscribe button on your screen. So let’s start with the first question.

How many types of gaskets are used in piping?

A gasket can be broadly classified into three categories.

- Non-Metallic

- Metallic

- Composite

- You can see the table in which I have listed the most commonly used gasket against each category.

| Non-Metallic | Metallic – Ring Gasket | Composite |

|---|---|---|

| Compressed Non-Asbestos Fibre Gasket (CNAF) | Oval Ring Gasket | Spiral Wound Gaskets |

| PTFE Gasket | Octagonal Ring Gasket | Camprofile Gaskets |

| Rubber Gasket | Metal Jacketed Exchanger |

Compressed Non-Asbestos Fibre Gasket is known as a CNAF gasket, PTFE gasket, and rubber gasket are non-metallic type gaskets. These gaskets are used in a non-critical application where pressure and temperature are not involved.

CNAF and rubber gasket are used on an application such as utility water, or temporary line, whereas PTFE gasket is used for corrosive services where metal gasket cannot be used.

Metal gaskets are manufactured from a material such as Soft iron, Low Carbon steel, Stainless Steel, Monel, and Inconel. These gaskets are Also known as ring gaskets or RTJ gaskets. A metallic gasket is used in high-pressure class flanges, normally above 900 Class; they can also be used in high-pressure-temperature services.

Composite gaskets are a combination of metal and non-metal materials. Different types of combinations of materials are possible based on service requirements. Spiral wounds, Metal Jacketed, and camprofile gaskets are well known in the composite gasket category.

They can be used in a wide range of pressure and temperature. Composite gaskets are Cost-effective with compare to metal gaskets, but Careful handling is required.

What is the most commonly used gasket material for temporary piping?

Now you should be able to answer this question as I have already explained to you about different types of gaskets. CNAF is Compressed Non-Asbestos Fibre Gasket is the most commonly used gasket material for temporary piping that handles non-hazardous material.

Please note that in most refinery and petrochemical plants where hydrocarbon and other such hazardous material is involved, the use of a CNAF gasket is not allowed.

Gasket Quiz – Test yourself, Take This Quiz

Unlock New Skills with Our Best Selling Online Courses

Which are the most commonly used gasket types for process piping?

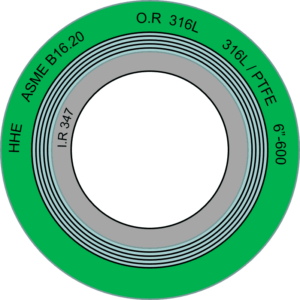

A spiral wound gasket is the most commonly used gasket type for the process piping. I have a video on the spiral wound gasket. You can watch the same if you want to learn more about the same. The link is given in the description.

Which type of gasket is used for high-pressure piping?

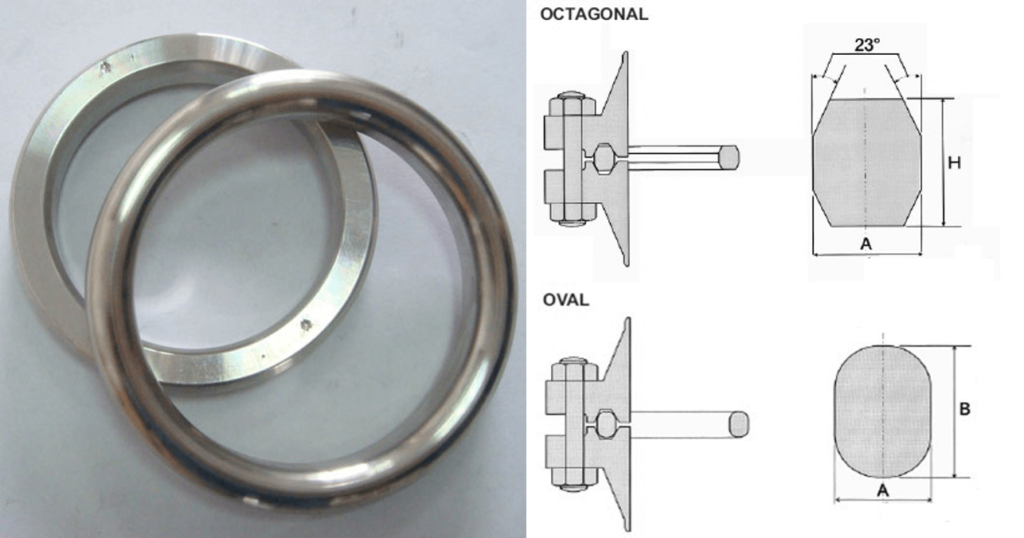

To answer this question, you should know the type of flange used in high-pressure piping. RTJ face flanges are used for high-pressure-temperature applications. With the RTJ flange, you have to use a Ring gasket. Here you can see the metallic ring-type gasket.

Two types of the metallic gasket are used with RTJ flange. The first is Octagonal, and the second is Oval. You can see the difference in their cross-section view.

What are the criteria for the selection of Gasket?

Proper selection of gasket depends upon the following factors.

- Compatibility of the gasket material with the fluid.

- Ability to withstand the pressure temperature of the system.

- The service life of the gasket.

Now, these three points are self-explanatory. When working with corrosive fluid, you need gasket material that can withstand in a corrosive environment. Similarly, for high-pressure applications, you cannot use non-metallic material.

Whether your gasket is used in temporary service or a service that is going to remain in operation for years before plan maintenance, your selection will get changed.

This is the end of the video. I hope that you have learned from this video. In the next video, I will explain to you a few more gaskets related questions. So keep on checking my youtube channel for a new videos.

Visit my website hardhatengineer.com for free study materials, and don’t forget to subscribe to my channel to get regular updates on new videos. Please like and share my video with your friends. If you want to request a video, please write in the comment. See you soon; goodbye, take care.

Are You Piping Components Master?