Welcome to Hardhatengineer.com. I am Varun Patel. In this video, you will learn about the most common questions regarding pipe flanges that you may face during the interview.

You will learn about these questions;

- What is the difference between the flange pressure class and schedule? Flange Class Vs. Flange Schedule

- Types of flange used in piping?

- What is the difference between a raised face and a flat face flange?

So please watch this video till the end. And don’t forget to subscribe to my channel; that way, you will get regular updates on a new videos. You can subscribe right now by just clicking the subscribe button on your screen. So let’s start with the first question.

What is the difference between the flange pressure class and schedule? Flange Class Vs. Flange Schedule

To answer this question, you should know about the flange rating. You must have heard about 150 class flanges or 300 class or 600 class flanges. What is this class? Flange class is a combination of pressure-temperature ratings that defines the flange’s maximum allowable working gauge pressure. Here the pressure is in a bar & the temperatures in degrees Celsius.

Based on this calculation, flanges are available in 150#, 300#, 400#, 600#, 900#, 1500#, and 2500#. Large diameter flanges that are 24” to 60” are available up to 900# class. In simple terms, you can know that the higher the rating, the heavier the flange, and it can withstand higher pressure and temperature.

Look at this image for your easy understanding. Here I have shown you class 150 flange and class 900 flange of the same size. You can see the difference in size.

Now you know what flange class is. But what about the flange schedule? Many people have asked me this question whether the same class flange can have a different schedule. The answer is yes. Now, look at this flange image.

This is a weld neck flange. This is a neck where a pipe is going to weld. If your pipe is having schedule 40, then your flange must have the same schedule so that there will be no miss-match in the internal diameter of the flange and pipe.

Now, if the same rating flange is used with schedule 80 pipe, your flange schedule will also change to 80. So, now you know that the flange class and schedule are two different things. Let’s move to the next question.

Types of flange used in piping?

The flange is the second most used joining method after welding. Flanges are used when joints need dismantling. Provides flexibility for maintenance.

Flange Connects the pipe with various equipment and valves. For this reason, different flanges are used depending on the pressure-temperature requirements. Here is the list.

- Weldneck flange

- Threaded Flanges

- Socket-Weld Flanges

- Slip-On Flanges

- Lap Joint Flanges

- Blind Flanges

If you want to learn more about these flanges, you can check my video on flange types. Let’s move to the next question.

Flange and Olet Quiz – Test yourself, Take This Quiz

Unlock New Skills with Our Best Selling Online Courses

What is the difference between a raised face and a flat face flange?

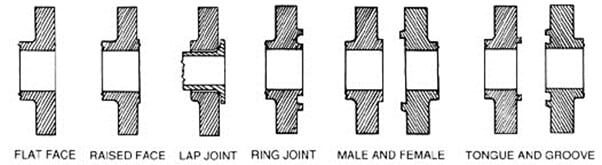

To answer this question, you must learn about different flange faces. In the image, you can see the different flange faces.

- Flat Face (FF)

- Raised Face (RF)

- Lap Joint

- Ring Joint (RTJ)

- Male and Female types

- And Tongue and groove (T&G)

Now out of these types, flat face, raised face, and RTJ face is regularly used in piping. Let’s learn about them. Check the image; you can see these three types of faces.

Flat Face

As the name suggests, a flat face flange has a flat face. Flat face flanges are used when the counter flange has a flat face. This condition occurs mainly in connection to Cast Iron equipment, valves, and specialties. A full-face non-metallic gasket is used when a flat face flange is used. This type of flange is not used in high pressure and temperature application.

Raised Face

Raised face flange has a small portion around the bore that is raised from the face. The gasket seat on this raised face. The height of the raised face depends on the flange pressure-temperature rating, which is known as a class of the flange. This type of flange is used in high pressure and temperature application.

RTJ Face

Ring joint type face flange has a specially designed grove in which metal gasket seats. This type of flange is used in very high pressure and temperature services.

This is the end of the video. I hope that you have learned from this video. In the next video, I will explain to you more flange-related questions. So keep on checking my youtube channel for a new videos.

Visit my website hardhatengineer.com for free study materials, and don’t forget to subscribe to my channel to get regular updates on new videos. Please like and share my video with your friends. If you want to request a video, please write in the comment. See you soon. Goodbye, take care.

Are You Piping Components Master?