In this video, I am going to teach you about the Elbow manufacturing process. There are four well-known Pipe Elbow Manufacturing Processes.

Mandrel method, Extrusion Method, UO Method, and Hot Forming Method.

Please subscribe to my channel to get regular updates on new videos and also like and share this video with your friends. Please write in the comment box if you have any questions or want to know something different. If you are a first-time visitor, I have a free gift at the end of the video, so please do watch until the end.

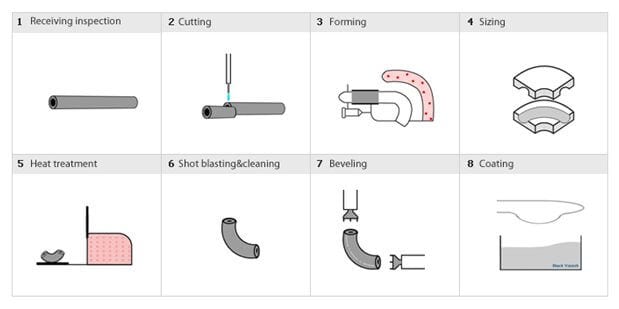

Let’s start with the Mandrel method.

ELBOWS: Mandrel method (Hot Forming)

- One of the most common manufacturing processes for Elbows from the pipe is a mandrel method, a kind of hot forming method.

- In this method, a pipe is cut into pieces and pushed with the help of a hydraulic ram. The induction heating coil heats the pipe and is pushed over a die called a “mandrel,” which allows the pipe to expand and bend simultaneously.

- This method can be used to manufacture a wide range of the diameter of elbows. In these graphics, you can see that pipe is cut into the desired length in the first step. This cut pipe is then set on the mandrel to die. In the next step, with the help of hydraulic rem pipe is pushed on the die, and at the same time induction coil heat the pipe pieces resulting in the elbow. In the next stage, the elbow is sent for heat treatment and machining before its offer for visual and dimension inspection.

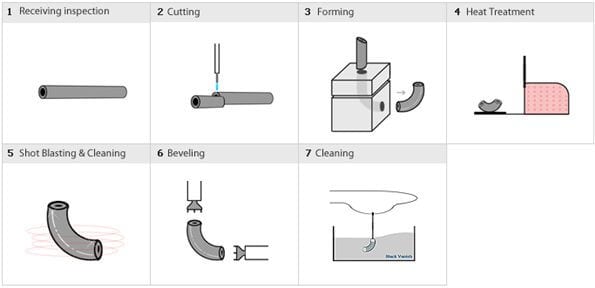

Extrusion Method

In the cold extrusion method, a pipe with the same diameter as a finished product is pushed through a die and formed into its desired shape. Usually applied to stainless steel small to medium sizes elbows.

Here, a cut pipe piece is pushed into the cold bending die. Proper lubrication is required to avoid excessive friction and protect the surface finish of the final elbow. In the next stage, the elbow is sent for heat treatment and machining before its offered for visual and dimension inspection.

Pipe FIttings Quiz – Test yourself, Take This Quiz

Unlock New Skills with Our Best Selling Online Courses

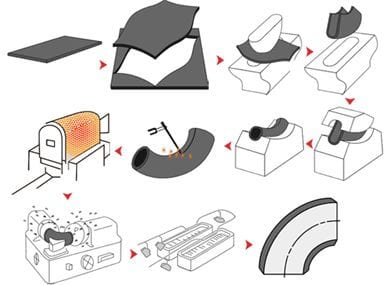

UO Method

UO method is used to manufacture medium size elbows, tee, and reducers. The plate is cut out into a specially designed shape; it is formed first into a U-shape using a die and then into an O-shape or a tubular form using another die; that is why this method is known as the UO method.

Once the fittings are tumbler shaped, they are welded from inside and outside of the closing seam. A very large size elbows are made of two separate pieces of plate. But follow the same process. Here you can see the same. In the next stage, the elbow is sent for heat treatment and machining before its offered for visual and dimension inspection.

Image Source: wermac.org

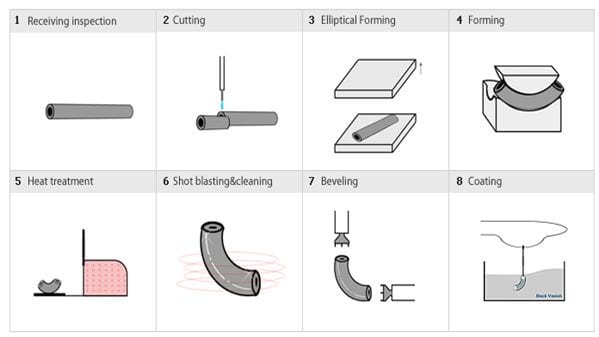

Hot Forming Method

In a Hot Forming Die Bending method, a Pipe is heated to forming temperature & formed in the die with the specific shape; this process may be repeated as needed to obtain the required shape, size, and wall thickness. Usually applied to thick-wall items that cannot be bent on a mandrel die.

Image Source: TK Fittings

Don’t forget to subscribe to my channel to get regular updates on new videos and also like and share my video with your friends. If you want to request a video, please write in the comment below. And don’t forget to check the free piping component guide by visiting my website. See you soon, goodbye, take care.

Are You Piping Components Master?