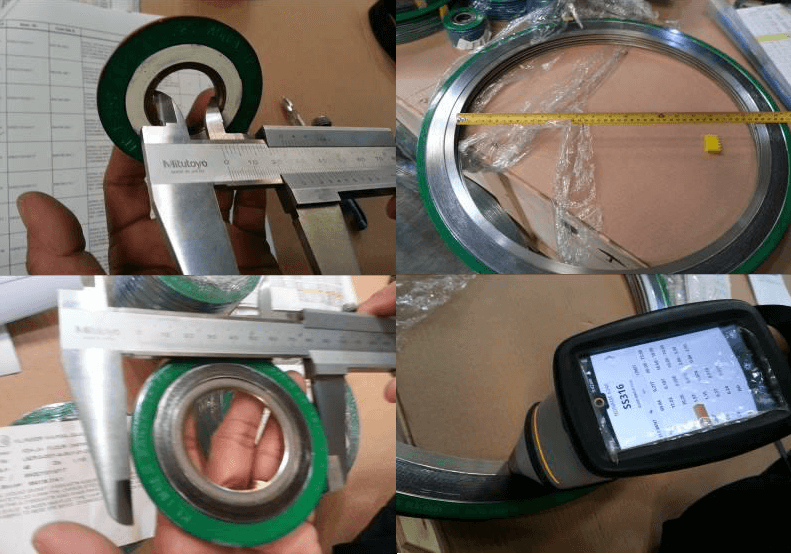

During the inspection of Spiral Wound Gasket Dimensions, you should check for

- Diameter – Inside / Outside

- Thickness

- Centering ring dimensions

- Permissible Variations of Gasket dimensions are covered in

- ASME B16.20– that covered dimensions for Metallic Gaskets such as Ring-Joint, Spiral-Wound, and Jacketed

Spiral Wound Gasket Dimensions Tables

Class 150 and Class 300 Spiral Gasket Dimensions

| NPS) | Classes 150, 300 | Class 150 | Class 300 | Class 150 | Class 300 |

|---|---|---|---|---|---|

| Inch | mm | Inside Diameter | Outside Diameter | ||

| 1⁄2 | 31.8 | 19.1 | 19.1 | 47.8 | 54.1 |

| 3⁄4 | 39.6 | 25.4 | 25.4 | 57.2 | 66.8 |

| 1 | 47.8 | 31.8 | 31.8 | 66.8 | 73.2 |

| 1 1⁄4 | 60.5 | 47.8 | 47.8 | 76.2 | 82.6 |

| 1 1⁄2 | 69.9 | 54.1 | 54.1 | 85.9 | 95.3 |

| 2 | 85.9 | 69.9 | 69.9 | 104.9 | 111.3 |

| 2 1⁄2 | 98.6 | 82.6 | 82.6 | 124 | 130.3 |

| 3 | 120.7 | 101.6 | 101.6 | 136.7 | 149.4 |

| 4 | 149.4 | 127 | 127 | 174.8 | 181.1 |

| 5 | 177.8 | 155.7 | 155.7 | 196.9 | 215.9 |

| 6 | 209.6 | 182.6 | 182.6 | 222.3 | 251 |

| 8 | 263.7 | 233.4 | 233.4 | 279.4 | 308.1 |

| 10 | 317.5 | 287.3 | 287.3 | 339.9 | 362 |

| 12 | 374.7 | 339.9 | 339.9 | 409.7 | 422.4 |

| 14 | 406.4 | 371.6 | 371.6 | 450.9 | 485.9 |

| 16 | 463.6 | 422.4 | 422.4 | 514.4 | 539.8 |

| 18 | 527.1 | 474.7 | 474.7 | 549.4 | 596.9 |

| 20 | 577.9 | 525.5 | 525.5 | 606.6 | 654.1 |

| 24 | 685.8 | 628.7 | 628.7 | 717.6 | 774.7 |

Gasket Quiz – Test yourself, Take This Quiz

Unlock New Skills with Our Best Selling Online Courses

Class 400 and Class 600 Spiral Gasket Dimensions

| (NPS) | Classes 400, 600 | Class 400 | Class 600 | Class 400 | Class 600 |

|---|---|---|---|---|---|

| Inch | mm | Inside Diameter | Outside Diameter | ||

| 1⁄2 | 31.8 | . | 19.1 | . | 54.1 |

| 3⁄4 | 39.6 | . | 25.4 | . | 66.8 |

| 1 | 47.8 | . | 31.8 | . | 73.2 |

| 1 1⁄4 | 60.5 | . | 47.8 | . | 82.6 |

| 1 1⁄2 | 69.9 | . | 54.1 | . | 95.3 |

| 2 | 85.9 | . | 69.9 | . | 111.3 |

| 2 1⁄2 | 98.6 | . | 82.6 | . | 130.3 |

| 3 | 120.7 | . | 101.6 | . | 149.4 |

| 4 | 149.4 | 120.7 | 120.7 | 177.8 | 193.8 |

| 5 | 177.8 | 147.6 | 147.6 | 212.9 | 241.3 |

| 6 | 209.6 | 174.8 | 174.8 | 247.7 | 266.7 |

| 8 | 263.7 | 225.6 | 225.6 | 304.8 | 320.8 |

| 10 | 317.5 | 274.6 | 274.6 | 358.9 | 400.1 |

| 12 | 374.7 | 327.2 | 327.2 | 419.1 | 457.2 |

| 14 | 406.4 | 362 | 362 | 482.6 | 492.3 |

| 16 | 463.6 | 412.8 | 412.8 | 536.7 | 565.2 |

| 18 | 527.1 | 469.9 | 469.9 | 593.9 | 612.9 |

| 20 | 577.9 | 520.7 | 520.7 | 647.7 | 682.8 |

| 24 | 685.8 | 628.7 | 628.7 | 768.4 | 790.7 |

Class 900 and Class 1500 Spiral Wound Gasket Dimensions

| (NPS) | Classes 900, 1500 | Class 900 | Class 1500 | Class 900 | Class 1500 |

|---|---|---|---|---|---|

| Inch | mm | Inside Diameter | Outside Diameter | ||

| 1⁄2 | 31.8 | . | 19.1 | . | 63.5 |

| 3⁄4 | 39.6 | . | 25.4 | . | 69.9 |

| 1 | 47.8 | . | 31.8 | . | 79.5 |

| 1 1⁄4 | 60.5 | . | 39.6 | . | 88.9 |

| 1 1⁄2 | 69.9 | . | 47.8 | . | 98.6 |

| 2 | 85.9 | . | 58.7 | . | 143 |

| 2 1⁄2 | 98.6 | . | 69.9 | . | 165.1 |

| 3 | 120.7 | 95.3 | 92.2 | 168.4 | 174.8 |

| 4 | 149.4 | 120.7 | 117.6 | 206.5 | 209.6 |

| 5 | 177.8 | 147.6 | 143 | 247.7 | 254 |

| 6 | 209.6 | 174.8 | 171.5 | 289.1 | 282.7 |

| 8 | 263.7 | 222.3 | 215.9 | 358.9 | 352.6 |

| 10 | 317.5 | 276.4 | 266.7 | 435.1 | 435.1 |

| 12 | 374.7 | 323.9 | 323.9 | 498.6 | 520.7 |

| 14 | 406.4 | 355.6 | 362 | 520.7 | 577.9 |

| 16 | 463.6 | 412.8 | 406.4 | 574.8 | 641.4 |

| 18 | 527.1 | 463.6 | 463.6 | 638.3 | 704.9 |

| 20 | 577.9 | 520.7 | 514.4 | 698.5 | 755.7 |

| 24 | 685.8 | 628.7 | 616 | 838.2 | 901.7 |

Class 2500 Spiral Wound Gasket Dimensions

| (NPS) | Class 2500 | Class 2500 | Class 2500 | ||

|---|---|---|---|---|---|

| Inch | mm | Inside Diameter | Outside Diameter | ||

| 1⁄2 | 31.8 | 19.1 | 69.9 | ||

| 3⁄4 | 39.6 | 25.4 | 76.2 | ||

| 1 | 47.8 | 31.8 | 85.9 | ||

| 1 1⁄4 | 60.5 | 39.6 | 104.9 | ||

| 1 1⁄2 | 69.9 | 47.8 | 117.6 | ||

| 2 | 85.9 | 58.7 | 146.1 | ||

| 2 1⁄2 | 98.6 | 69.9 | 168.4 | ||

| 3 | 120.7 | 92.2 | 196.9 | ||

| 4 | 149.4 | 117.6 | 235 | ||

| 5 | 177.8 | 143 | 279.4 | ||

| 6 | 209.6 | 171.5 | 317.5 | ||

| 8 | 263.7 | 215.9 | 387.4 | ||

| 10 | 317.5 | 270 | 476.3 | ||

| 12 | 374.7 | 317.5 | 549.4 | ||

All dimensions are in millimeters.

Tolerance in the Dimension of the Spiral Gasket

- Thickness tolerance is ±0.13 mm measured across the metallic portion of the gasket, not including the filler, which may protrude slightly beyond the metal.

- Outside diameter tolerance for NPS 1⁄2 through NPS 8 is ±0.8 mm; for NPS 10 through NPS 24, +1.5 mm, −0.8 mm.

- Inside diameter tolerance for NPS 1⁄2 through NPS 8 is ±0.4 mm; for NPS 10 through NPS 24, ±0.8 mm.

- The centering ring outside diameter tolerance is ±0.8 mm.

Are You Piping Components Master?