A pipe schedule chart is used to verify the dimension of the carbon steel and stainless steel pipe used in process industries. These charts covered sizes and schedules that give you the thickness of the pipe. ASME B36.10 and ASME B36.19 covered the Carbon steel and Stainless steel pipe dimensions, respectively. But do you know what the Pipe Schedule is?

What is Pipe Schedule?

The pipe schedule is the way pipe wall thickness is mentioned. To simplify the ordering of the pipe ASME committee has developed Schedule Number, which is based on modified Barlow’s wall thickness formula.

Definition of Schedule Number: The schedule number indicates an approximate value of 1000 x P/S where P is the service pressure and S is the allowable stress, expressed in pounds per square inch.

You can see the pipe schedule calculation formula below;

Schedule number = P/S

- P is the service pressure in (psi)

- S is the allowable stress in (psi)

So, what does schedule 40 means?

Schedule 40 is nothing but a pipe thickness designator. In simple words, you can say that for a given material, schedule 40 pipes can withstand a certain amount of pressure.

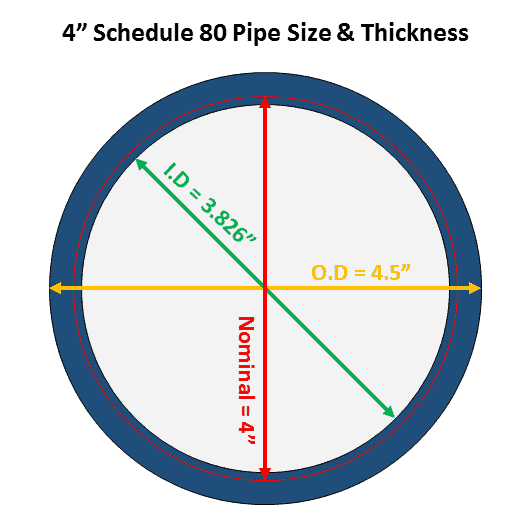

Pipe Schedule Chart for Carbon Steel Pipe in Inches

Schedule 5, Schedule 10 and Schedule 30

| Nominal Pipe Schedule Chart for Sch5, 10 and 30 in Inches | |||||

|---|---|---|---|---|---|

| Nominal Pipe Size in Inch | OD in Inch | 5 | 10 | 20 | 30 |

| 1/8 | 0.405 | 0.049 | |||

| 1/4 | 0.54 | 0.065 | |||

| 3/8 | 0.675 | 0.065 | 0.073 | ||

| 1/2 | 0.84 | 0.065 | 0.083 | 0.095 | |

| 3/4 | 1.05 | 0.065 | 0.083 | 0.095 | |

| 1 | 1.315 | 0.065 | 0.109 | 0.114 | |

| 1 1/4 | 1.66 | 0.065 | 0.109 | 0.117 | |

| 1 1/2 | 1.9 | 0.065 | 0.109 | 0.125 | |

| 2 | 2.375 | 0.065 | 0.109 | 0.125 | |

| 2 1/2 | 2.875 | 0.083 | 0.12 | 0.188 | |

| 3 | 3.5 | 0.083 | 0.12 | 0.188 | |

| 3 1/2 | 4 | 0.083 | 0.12 | 0.188 | |

| 4 | 4.5 | 0.083 | 0.12 | 0.188 | |

| 5 | 5.563 | 0.109 | 0.134 | ||

| 6 | 6.625 | 0.109 | 0.134 | ||

| 8 | 8.625 | 0.109 | 0.148 | 0.25 | 0.277 |

| 10 | 10.75 | 0.134 | 0.165 | 0.25 | 0.307 |

| 12 | 12.75 | 0.156 | 0.18 | 0.25 | 0.33 |

| 14 | 14 | 0.156 | 0.25 | 0.312 | 0.375 |

| 16 | 16 | 0.165 | 0.25 | 0.312 | 0.375 |

| 18 | 18 | 0.165 | 0.25 | 0.312 | 0.438 |

| 20 | 20 | 0.188 | 0.25 | 0.375 | 0.5 |

| 22 | 22 | 0.188 | 0.25 | 0.375 | 0.5 |

| 24 | 24 | 0.218 | 0.25 | 0.375 | 0.562 |

| 26 | 26 | 0.312 | 0.5 | ||

| 28 | 28 | 0.312 | 0.5 | 0.625 | |

| 30 | 30 | 0.25 | 0.312 | 0.5 | 0.625 |

| 32 | 32 | 0.312 | 0.5 | 0.625 | |

| 34 | 34 | 0.312 | 0.5 | 0.625 | |

| 36 | 36 | 0.312 | 0.5 | 0.625 | |

| ASME B36.10M-2015: Welded and Seamless Wrought Steel Pipe | |||||

| Don’t get confused between 3 1/2 inch nominal with 3.5 inch OD, 4″ nominal with 4.000″ OD | |||||

Piping Component Quiz – Test yourself, Take This Quiz

Unlock New Skills with Our Best Selling Online Courses

Schedule 40, Schedule STD, Schedule 60, Schedule 80, and Schedule XS

| Nominal Pipe Schedule Chart for Sch 40, STD, 60, 80 & Xs in Inches | ||||||

|---|---|---|---|---|---|---|

| Nominal Pipe Size in Inch | OD in Inch | 40 | Std | 60 | 80 | XS |

| 1/8 | 0.405 | 0.068 | 0.068 | 0.095 | 0.095 | |

| 1/4 | 0.54 | 0.088 | 0.088 | 0.119 | 0.119 | |

| 3/8 | 0.675 | 0.091 | 0.091 | 0.126 | 0.126 | |

| 1/2 | 0.84 | 0.109 | 0.109 | 0.147 | 0.147 | |

| 3/4 | 1.05 | 0.113 | 0.113 | 0.154 | 0.154 | |

| 1 | 1.315 | 0.133 | 0.133 | 0.179 | 0.179 | |

| 1 1/4 | 1.66 | 0.14 | 0.14 | 0.191 | 0.191 | |

| 1 1/2 | 1.9 | 0.145 | 0.145 | 0.2 | 0.2 | |

| 2 | 2.375 | 0.154 | 0.154 | 0.218 | 0.218 | |

| 2 1/2 | 2.875 | 0.203 | 0.203 | 0.276 | 0.276 | |

| 3 | 3.5 | 0.216 | 0.216 | 0.3 | 0.3 | |

| 3 1/2 | 4 | 0.226 | 0.226 | 0.318 | 0.318 | |

| 4 | 4.5 | 0.237 | 0.237 | 0.337 | 0.337 | |

| 5 | 5.563 | 0.258 | 0.258 | 0.375 | 0.375 | |

| 6 | 6.625 | 0.28 | 0.28 | 0.432 | 0.432 | |

| 8 | 8.625 | 0.322 | 0.322 | 0.406 | 0.5 | 0.5 |

| 10 | 10.75 | 0.365 | 0.365 | 0.5 | 0.594 | 0.5 |

| 12 | 12.75 | 0.406 | 0.375 | 0.562 | 0.688 | 0.5 |

| 14 | 14 | 0.438 | 0.375 | 0.594 | 0.75 | 0.5 |

| 16 | 16 | 0.5 | 0.375 | 0.656 | 0.844 | 0.5 |

| 18 | 18 | 0.562 | 0.375 | 0.75 | 0.938 | 0.5 |

| 20 | 20 | 0.594 | 0.375 | 0.812 | 1.031 | 0.5 |

| 22 | 22 | 0.375 | 0.875 | 1.125 | 0.5 | |

| 24 | 24 | 0.688 | 0.375 | 0.969 | 1.219 | 0.5 |

| 26 | 26 | 0.375 | 0.5 | |||

| 28 | 28 | 0.375 | 0.5 | |||

| 30 | 30 | 0.375 | 0.5 | |||

| 32 | 32 | 0.688 | 0.375 | 0.5 | ||

| 34 | 34 | 0.688 | 0.375 | 0.5 | ||

| 36 | 36 | 0.75 | 0.375 | 0.5 | ||

| ASME B36.10M-2015: Welded and Seamless Wrought Steel Pipe | ||||||

| Don’t get confused between 3 1/2 inch nominal with 3.5 inch OD, 4″ nominal with 4.000″ OD | ||||||

Schedule 100, Schedule 120, Schedule 140, Schedule 160, and Schedule XXS

| Nominal Pipe Schedule Chart for Sch 100, 120,140, 160 & XXS in Inches | ||||||

|---|---|---|---|---|---|---|

| Nominal Pipe Size in Inch | OD in Inch | 100 | 120 | 140 | 160 | XXS |

| 1/2 | 0.84 | 0.188 | 0.294 | |||

| 3/4 | 1.05 | 0.219 | 0.308 | |||

| 1 | 1.315 | 0.25 | 0.358 | |||

| 1 1/4 | 1.66 | 0.25 | 0.382 | |||

| 1 1/2 | 1.9 | 0.281 | 0.4 | |||

| 2 | 2.375 | 0.344 | 0.436 | |||

| 2 1/2 | 2.875 | 0.375 | 0.552 | |||

| 3 | 3.5 | 0.438 | 0.6 | |||

| 3 1/2 | 4 | 0.636 | ||||

| 4 | 4.5 | 0.438 | 0.531 | 0.674 | ||

| 5 | 5.563 | 0.5 | 0.625 | 0.75 | ||

| 6 | 6.625 | 0.562 | 0.719 | 0.864 | ||

| 8 | 8.625 | 0.594 | 0.719 | 0.812 | 0.906 | 0.875 |

| 10 | 10.75 | 0.719 | 0.844 | 1 | 1.125 | 1 |

| 12 | 12.75 | 0.844 | 1 | 1.125 | 1.312 | 1 |

| 14 | 14 | 0.938 | 1.094 | 1.25 | 1.406 | |

| 16 | 16 | 1.031 | 1.219 | 1.438 | 1.594 | |

| 18 | 18 | 1.156 | 1.375 | 1.562 | 1.781 | |

| 20 | 20 | 1.281 | 1.5 | 1.75 | 1.969 | |

| 22 | 22 | 1.375 | 1.625 | 1.875 | 2.125 | |

| 24 | 24 | 1.531 | 1.812 | 2.062 | 2.344 | |

| ASME B36.10M-2015: Welded and Seamless Wrought Steel Pipe | ||||||

| Don’t get confused between 3 1/2 inch nominal with 3.5 inch OD, 4″ nominal with 4.000″ OD | ||||||

Pipe Schedule Chart for Stainless Steel Pipe in Inches

| Nominal Pipe Schedule Chart for SS Pipes with Sch 5s, 10s, 40s and 80s in Inches | |||||

|---|---|---|---|---|---|

| Nominal Pipe Size in Inch | OD in Inch | 5S | 10S | 40S | 80S |

| 1/8 | 0.405 | 0.049 | 0.068 | 0.095 | |

| 1/4 | 0.54 | 0.065 | 0.088 | 0.119 | |

| 3/8 | 0.675 | 0.065 | 0.091 | 0.126 | |

| 1/2 | 0.84 | 0.065 | 0.083 | 0.109 | 0.147 |

| 3/4 | 1.05 | 0.065 | 0.083 | 0.113 | 0.154 |

| 1 | 1.315 | 0.065 | 0.109 | 0.133 | 0.179 |

| 1 1/4 | 1.66 | 0.065 | 0.109 | 0.14 | 0.191 |

| 1 1/2 | 1.9 | 0.065 | 0.109 | 0.145 | 0.2 |

| 2 | 2.375 | 0.065 | 0.109 | 0.154 | 0.218 |

| 2 1/2 | 2.875 | 0.083 | 0.12 | 0.203 | 0.276 |

| 3 | 3.5 | 0.083 | 0.12 | 0.216 | 0.3 |

| 3 1/2 | 4 | 0.083 | 0.12 | 0.226 | 0.318 |

| 4 | 4.5 | 0.083 | 0.12 | 0.237 | 0.337 |

| 5 | 5.563 | 0.109 | 0.134 | 0.258 | 0.375 |

| 6 | 6.625 | 0.109 | 0.134 | 0.28 | 0.432 |

| 8 | 8.625 | 0.109 | 0.148 | 0.322 | 0.5 |

| 10 | 10.75 | 0.134 | 0.165 | 0.365 | 0.5 |

| 12 | 12.75 | 0.156 | 0.18 | 0.375 | 0.5 |

| 14 | 14 | 0.156 | 0.188 | 0.375 | 0.5 |

| 16 | 16 | 0.165 | 0.188 | 0.375 | 0.5 |

| 18 | 18 | 0.165 | 0.188 | 0.375 | 0.5 |

| 20 | 20 | 0.188 | 0.218 | 0.375 | 0.5 |

| 22 | 22 | 0.188 | 0.218 | ||

| 24 | 24 | 0.218 | 0.25 | 0.375 | 0.5 |

| 30 | 30 | 0.25 | 0.312 | ||

| ASME B36.19M-2004: Stainless Steel Pipe (For 5S,10S,40S and 80S) | |||||

| Don’t get confused between 3 1/2 inch nominal with 3.5 inch OD, 4″ nominal with 4.000″ OD | |||||

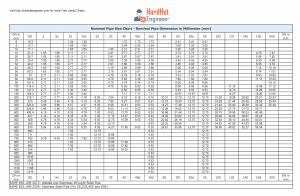

Pipe Schedule Chart for Carbon Steel Pipe in Millimeter

Schedule 5, Schedule 10, and Schedule 30

| Nominal Pipe Schedule Chart for Sch 5, 10, 20 and 30 in Millimeter (mm) | |||||

|---|---|---|---|---|---|

| DN in mm | OD | 5 | 10 | 20 | 30 |

| 6 | 10.3 | 1.24 | |||

| 8 | 13.7 | 1.65 | |||

| 10 | 17.1 | 1.65 | 1.85 | ||

| 15 | 21.3 | 1.65 | 2.11 | 2.41 | |

| 20 | 26.7 | 1.65 | 2.11 | 2.41 | |

| 25 | 33.4 | 1.65 | 2.77 | 2.9 | |

| 32 | 42.2 | 1.65 | 2.77 | 2.97 | |

| 40 | 48.3 | 1.65 | 2.77 | 3.18 | |

| 50 | 60.3 | 1.65 | 2.77 | 3.18 | |

| 65 | 73 | 2.11 | 3.05 | 4.78 | |

| 80 | 88.9 | 2.11 | 3.05 | 4.78 | |

| 90 | 101.6 | 2.11 | 3.05 | 4.78 | |

| 100 | 114.3 | 2.11 | 3.05 | 4.78 | |

| 125 | 141.3 | 2.77 | 3.4 | ||

| 150 | 168.3 | 2.77 | 3.4 | ||

| 200 | 219.1 | 2.77 | 3.76 | 6.35 | 7.04 |

| 250 | 273 | 3.4 | 4.19 | 6.35 | 7.8 |

| 300 | 323.8 | 3.96 | 4.57 | 6.35 | 8.38 |

| 350 | 355.6 | 3.96 | 6.35 | 7.92 | 9.53 |

| 400 | 406.4 | 4.19 | 6.35 | 7.92 | 9.53 |

| 450 | 457 | 4.19 | 6.35 | 7.92 | 11.13 |

| 500 | 508 | 4.78 | 6.35 | 9.53 | 12.7 |

| 550 | 559 | 4.78 | 6.35 | 9.53 | 12.7 |

| 600 | 610 | 5.54 | 6.35 | 9.53 | 14.27 |

| 650 | 660 | 7.92 | 12.7 | ||

| 700 | 711 | 7.92 | 12.7 | 15.88 | |

| 750 | 762 | 6.35 | 7.92 | 12.7 | 15.88 |

| 800 | 813 | 7.92 | 12.7 | 15.88 | |

| 850 | 864 | 7.92 | 12.7 | 15.88 | |

| 900 | 914 | 7.92 | 12.7 | 15.88 | |

| ASME B36.10M-2015: Welded and Seamless Wrought Steel Pipe | |||||

Unlock New Skills with Our Best Selling Online Courses

Schedule 40, Schedule STD, Schedule 60, Schedule 80, and Schedule XS

| Nominal Pipe Schedule Chart for Sch 40, Std, 60, 80 and XS in Millimeter (mm) | ||||||

|---|---|---|---|---|---|---|

| DN in mm | OD | 40 | Std | 60 | 80 | XS |

| 6 | 10.3 | 1.73 | 1.73 | 2.41 | 2.41 | |

| 8 | 13.7 | 2.24 | 2.24 | 3.02 | 3.02 | |

| 10 | 17.1 | 2.31 | 2.31 | 3.2 | 3.2 | |

| 15 | 21.3 | 2.77 | 2.77 | 3.73 | 3.73 | |

| 20 | 26.7 | 2.87 | 2.87 | 3.91 | 3.91 | |

| 25 | 33.4 | 3.38 | 3.38 | 4.55 | 4.55 | |

| 32 | 42.2 | 3.56 | 3.56 | 4.85 | 4.85 | |

| 40 | 48.3 | 3.68 | 3.68 | 5.08 | 5.08 | |

| 50 | 60.3 | 3.91 | 3.91 | 5.54 | 5.54 | |

| 65 | 73 | 5.16 | 5.16 | 7.01 | 7.01 | |

| 80 | 88.9 | 5.49 | 5.49 | 7.62 | 7.62 | |

| 90 | 101.6 | 5.74 | 5.74 | 8.08 | 8.08 | |

| 100 | 114.3 | 6.02 | 6.02 | 8.56 | 8.56 | |

| 125 | 141.3 | 6.55 | 6.55 | 9.53 | 9.53 | |

| 150 | 168.3 | 7.11 | 7.11 | 10.97 | 10.97 | |

| 200 | 219.1 | 8.18 | 8.18 | 10.31 | 12.7 | 12.7 |

| 250 | 273 | 9.27 | 9.27 | 12.7 | 15.09 | 12.7 |

| 300 | 323.8 | 10.31 | 9.53 | 14.27 | 17.48 | 12.7 |

| 350 | 355.6 | 11.13 | 9.53 | 15.09 | 19.05 | 12.7 |

| 400 | 406.4 | 12.7 | 9.53 | 16.66 | 21.44 | 12.7 |

| 450 | 457 | 14.27 | 9.53 | 19.05 | 23.83 | 12.7 |

| 500 | 508 | 15.09 | 9.53 | 20.62 | 26.19 | 12.7 |

| 550 | 559 | 9.53 | 22.23 | 28.58 | 12.7 | |

| 600 | 610 | 17.48 | 9.53 | 24.61 | 30.96 | 12.7 |

| 650 | 660 | 9.53 | 12.7 | |||

| 700 | 711 | 9.53 | 12.7 | |||

| 750 | 762 | 9.53 | 12.7 | |||

| 800 | 813 | 17.48 | 9.53 | 12.7 | ||

| 850 | 864 | 17.48 | 9.53 | 12.7 | ||

| 900 | 914 | 19.05 | 9.53 | 12.7 | ||

| 950 | 965 | 9.53 | 12.7 | |||

| 1000 | 1016 | 9.53 | 12.7 | |||

| 1050 | 1067 | 9.53 | 12.7 | |||

| 1100 | 1118 | 9.53 | 12.7 | |||

| 1150 | 1168 | 9.53 | 12.7 | |||

| 1200 | 1219 | 9.53 | 12.7 | |||

| ASME B36.10M-2015: Welded and Seamless Wrought Steel Pipe | ||||||

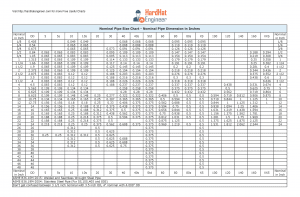

Schedule 100, Schedule 120, Schedule 140, Schedule 160, and Schedule XXS

| Nominal Pipe Schedule Chart for Sch 100, 120, 140, 160 and XXS in Millimeter (mm) | ||||||

|---|---|---|---|---|---|---|

| DN in mm | OD | 100 | 120 | 140 | 160 | XXS |

| 15 | 21.3 | 4.78 | 7.47 | |||

| 20 | 26.7 | 5.56 | 7.82 | |||

| 25 | 33.4 | 6.35 | 9.09 | |||

| 32 | 42.2 | 6.35 | 9.7 | |||

| 40 | 48.3 | 7.14 | 10.16 | |||

| 50 | 60.3 | 8.74 | 11.07 | |||

| 65 | 73 | 9.53 | 14.02 | |||

| 80 | 88.9 | 11.13 | 15.24 | |||

| 90 | 101.6 | 16.15 | ||||

| 100 | 114.3 | 11.13 | 13.49 | 17.12 | ||

| 125 | 141.3 | 12.7 | 15.88 | 19.05 | ||

| 150 | 168.3 | 14.27 | 18.26 | 21.95 | ||

| 200 | 219.1 | 15.09 | 18.26 | 20.62 | 23.01 | 22.23 |

| 250 | 273 | 18.26 | 21.44 | 25.4 | 28.58 | 25.4 |

| 300 | 323.8 | 21.44 | 25.4 | 28.58 | 33.32 | 25.4 |

| 350 | 355.6 | 23.83 | 27.79 | 31.75 | 35.71 | |

| 400 | 406.4 | 26.19 | 30.96 | 36.53 | 40.49 | |

| 450 | 457 | 29.36 | 34.93 | 39.67 | 45.24 | |

| 500 | 508 | 32.54 | 38.1 | 44.45 | 50.01 | |

| 550 | 559 | 34.93 | 41.28 | 47.63 | 53.98 | |

| 600 | 610 | 38.89 | 46.02 | 52.37 | 59.54 | |

| ASME B36.10M-2015: Welded and Seamless Wrought Steel Pipe | ||||||

Pipe Schedule Chart for Stainless Steel Pipe in Millimeter

| Nominal Pipe Schedule Chart for SS Pipe Sch 5s, 10s, 40s and 80s in Millimeter (mm) | |||||

|---|---|---|---|---|---|

| DN in mm | OD | 5s | 10s | 40s | 80s |

| 6 | 10.3 | 1.24 | 1.73 | 2.41 | |

| 8 | 13.7 | 1.65 | 2.24 | 3.02 | |

| 10 | 17.1 | 1.65 | 2.31 | 3.2 | |

| 15 | 21.3 | 1.65 | 2.11 | 2.77 | 3.73 |

| 20 | 26.7 | 1.65 | 2.11 | 2.87 | 3.91 |

| 25 | 33.4 | 1.65 | 2.77 | 3.38 | 4.55 |

| 32 | 42.2 | 1.65 | 2.77 | 3.56 | 4.85 |

| 40 | 48.3 | 1.65 | 2.77 | 3.68 | 5.08 |

| 50 | 60.3 | 1.65 | 2.77 | 3.91 | 5.54 |

| 65 | 73 | 2.11 | 3.05 | 5.16 | 7.01 |

| 80 | 88.9 | 2.11 | 3.05 | 5.49 | 7.62 |

| 90 | 101.6 | 2.11 | 3.05 | 5.74 | 8.08 |

| 100 | 114.3 | 2.11 | 3.05 | 6.02 | 8.56 |

| 125 | 141.3 | 2.77 | 3.4 | 6.55 | 9.53 |

| 150 | 168.3 | 2.77 | 3.4 | 7.11 | 10.97 |

| 200 | 219.1 | 2.77 | 3.76 | 8.18 | 12.7 |

| 250 | 273 | 3.4 | 4.19 | 9.27 | 12.7 |

| 300 | 323.8 | 3.96 | 4.57 | 9.53 | 12.7 |

| 350 | 355.6 | 3.96 | 4.78 | 9.53 | 12.7 |

| 400 | 406.4 | 4.19 | 4.78 | 9.53 | 12.7 |

| 450 | 457 | 4.19 | 4.78 | 9.53 | 12.7 |

| 500 | 508 | 4.78 | 5.54 | 9.53 | 12.7 |

| 550 | 559 | 4.78 | 5.54 | ||

| 600 | 610 | 5.54 | 6.35 | 9.53 | 12.7 |

| 750 | 762 | 6.35 | 7.92 | ||

| ASME B36.19M-2004: Stainless Steel Pipe (For 5S,10S,40S and 80S) | |||||

Are You Piping Components Master?