In this blog, you will learn about the Rising Stem and the Non-Rising Stem Gate Valve. You’ll have a clear understanding of the differences between these two types of valves, how they work, and where they are used.

Table of Contents

Rising Stem Gate Valve / OS & Y Gate Valve

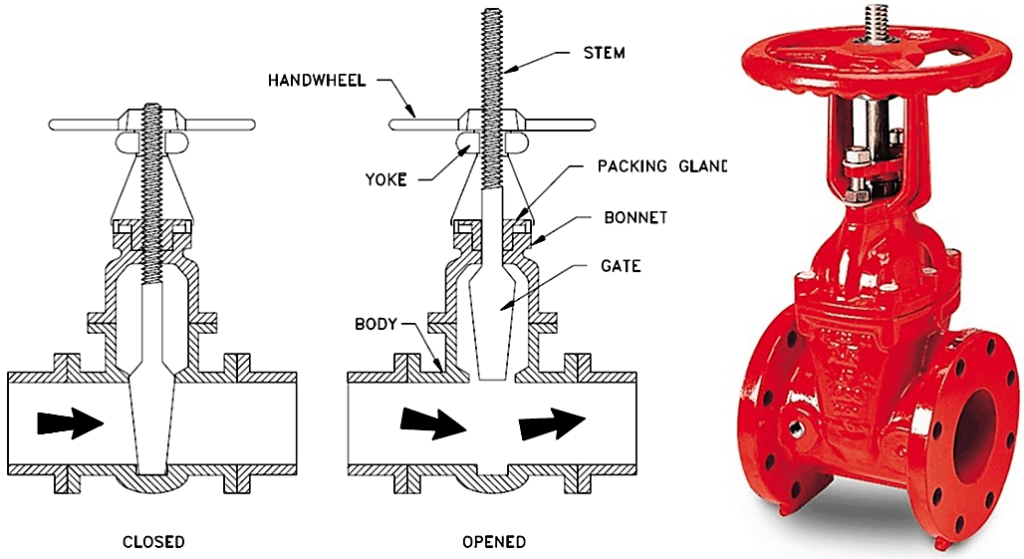

Now, I assume that you are aware of the gate valve as shown here. It uses a gate or wedge-shaped disc to stop the flow of fluid. It’s commonly used in various process industries including oil and gas.

The type of gate valve you are looking at is the Rising Stem Gate Valve, also known as the OS & Y Gate Valve. ‘OS & Y’ stands for Outside Stem and Yoke.

In a rising stem valve, the stem moves up and down as you open and close the valve. This upward and downward movement is quite visible, and that’s one of the main advantages of this design.

It gives you a clear visual indication of whether the valve is open, or closed.

In this type of design, the threaded portion of the stem is outside the valve body, which means it’s not in contact with the fluid medium. This design helps protect the stem from corrosion and wear if the fluid is corrosive.

The stem is attached to the valve disc and rises above when the handwheel moved, giving that clear visual indication of valve position.

Advantages of OS & Y Gate Valve are

- Clear visual indication of valve position

- Easier maintenance and inspection

- Suitable for corrosive or erosive environments because of outside screw design

Hey there! If you want to learn about 18 types of valves, their sub types and testing, you can check my full course on Piping Valves. It is extremely affordable with lifetime access and comes with a 30 days no question asked money back guarantee. So, don’t forget to check.

Unlock New Skills with Our Best Selling Online Courses

Valve Quiz – Test yourself, Take This Quiz

Non-Rising Stem Gate Valve / Inside Screw Valve

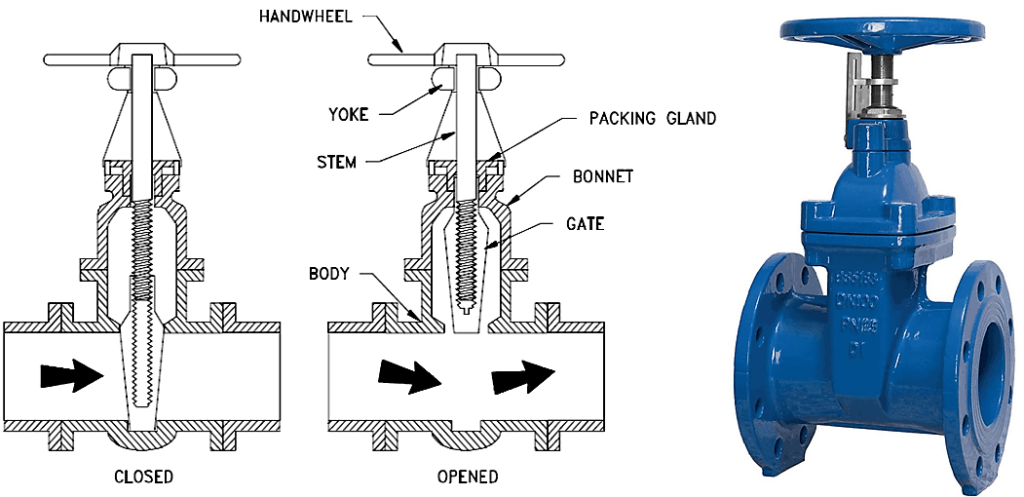

Next, let’s look at the Non-Rising Stem Gate Valve, also known as the Inside Screw Valve. Unlike the rising stem type, there is no upward movement of the stem here.

The stem is threaded internally into the valve disc. As the handwheel is turned, the disc moves up and down along the stem like a nut on a bolt, without the stem moving up or down.

This design is compact, making it ideal for situations where space is limited. Since the stem does not rise, these valves are often used in underground applications or where headroom is restricted.

However, because the stem threads are exposed to the fluid medium, this type of valve is more susceptible to corrosion and wear, especially if the medium is erosive or contains particulates.

Advantages and Disadvantages of Non-rising Stem Gate Valve

Advantage of the non-Rising Stem Gate Valve is that it is a Space-saving design, suitable for limited headroom or underground installations.

The disadvantage of this valve is that the stem threads are exposed to the medium, which can lead to faster wear in corrosive environments.

Use of Rising Stem Gate Valve versus a Non-Rising Stem Gate Valve

So, when should you use a Rising Stem Gate Valve versus a Non-Rising Stem Gate Valve? It really depends on your specific application needs.

For environments where you need a clear indication of whether the valve is open or closed, or where the fluid medium is corrosive, a Rising Stem Gate Valve is generally the better choice.

On the other hand, if you are dealing with space constraints, such as in underground pipelines or tight installations, or where the fluid is clean and non-corrosive, a Non-Rising Stem Gate Valve might be more suitable.