Welcome to Hardhatengineer.com. I am Varun Patel. In this video, you will learn about the most common questions regarding pipe flanges you may face during the interview.

You will learn about these questions;

- What is the height of the face in the raised face flange?

- What is serration on the flange face?

- What types of serration are used on flange faces?

- What are AARH and RMS?

- How to measure the serration?

So please watch this video till the end. And don’t forget to subscribe to my channel; that way, you will get regular updates on new videos. You can subscribe right now by clicking the subscribe button on your screen. So let’s start with the first question.

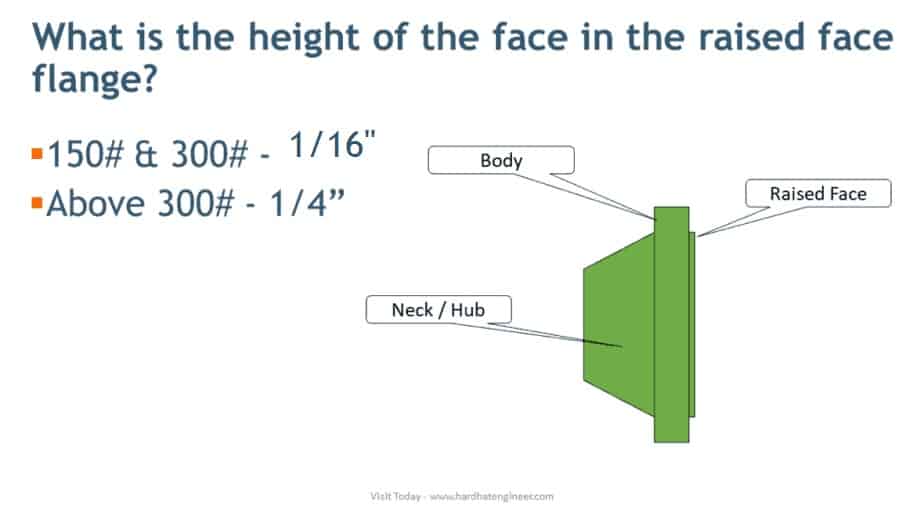

What is the height of the face in the raised face flange?

In the last video, I explained to you about flange faces. Now, look at this image of a flange. You can see the height of the face. It is not random height but based on the flange ratings. For 150# & 300#, the height of the raised face is 1/16”, which is approx. 1.6 mm, and above 300#, it is 1/4”, which is 6.35 mm. Let’s move to the second question.

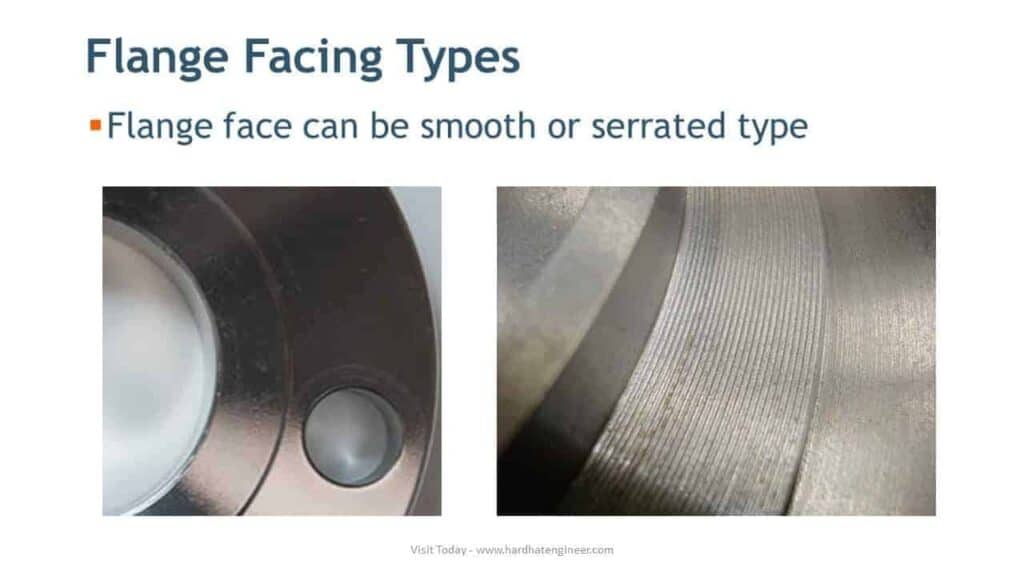

What is serration on the flange face?

Flange faces can be smooth or serrated type. Which type of face to use depends on the type of gasket and the service of the fluid. The flange face with small grooves, as you can see in the image; this machining is known as a serration.

This serration is very critical to prevent the leak from the flange. Even small damage to the face can lead to a plant shutdown. So, if you are working with a flange, you have to take measures to protect the flange while handling it. The next question is;

Flange and Olet Quiz – Test yourself, Take This Quiz

Unlock New Skills with Our Best Selling Online Courses

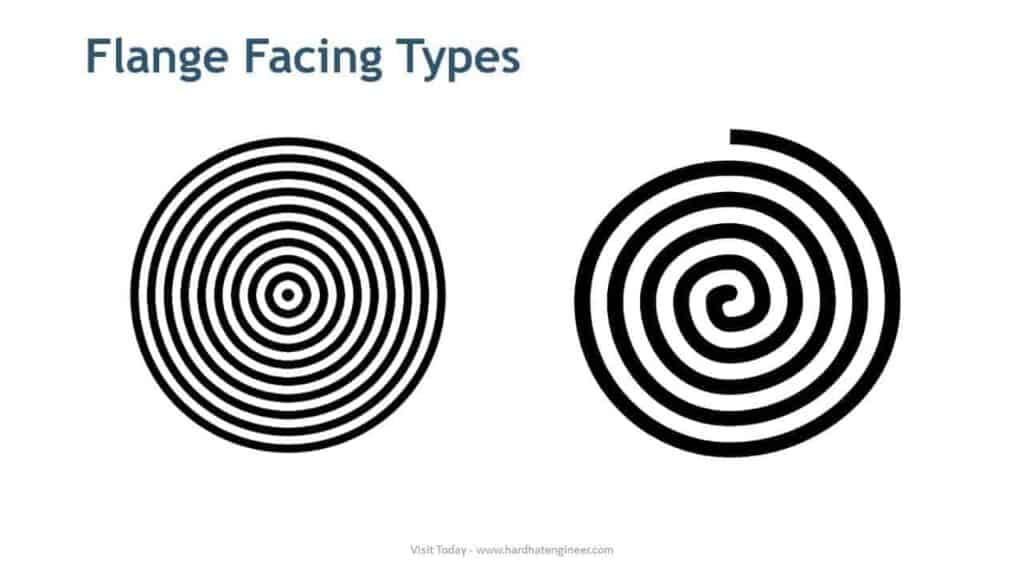

What types of serration are used on flange faces?

Serration can be spiral or concentric rings, as seen in the slide. Concentric ring type finishing is used when fluid is of very low density. If you use a spiral-type finish with very low-density fluid, it may find a leakage path through the spiral cavity.

What are AARH and RMS?

In the previous question, you learn about serration. Now, this machining is not random; it has to be perfect to prevent a leak. Small groves will not let gasket material sit in, and large groves will damage the gasket and increase corrosion of the face. Now the measurement value of the Serration of the flange face is specified in RMS (Root Mean Square) or AARH (Arithmetic Average Rough Height). These two are the units used to measure the roughness of the flange face. The most common value of a serrated face is 120-250 AARH.

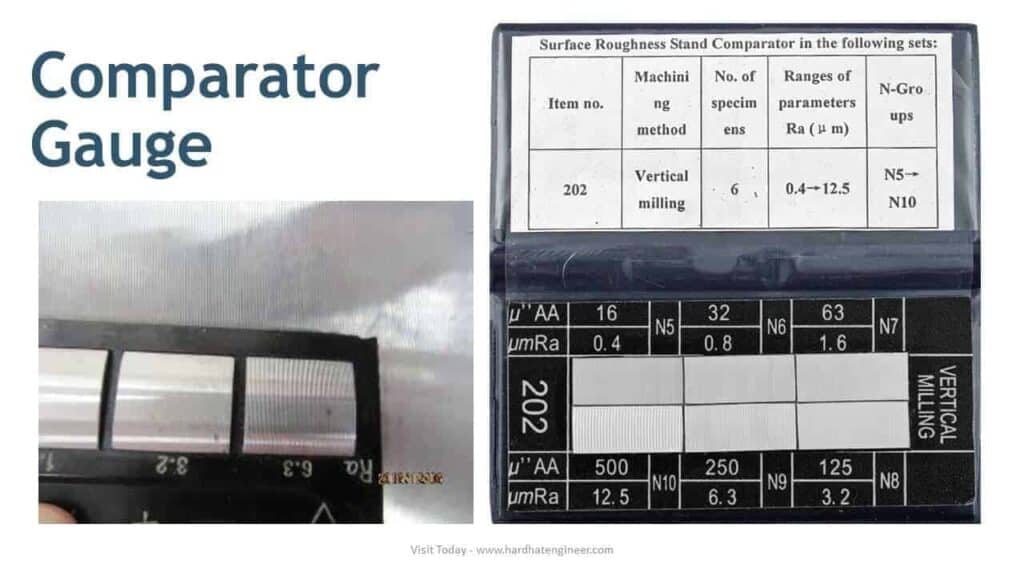

How to measure the serration?

Measuring the serration of the flange required a special gauge. This gauge is known as a comparator gauge. A comparator gauge is used to check the serration of the flange. In the image, you can see how a gauge is used to verify the value of serration.

You can see that gauge has actual machining samples of different values. As the name suggests, you match this sample with your flange machining. This way, you can measure actual value, but it will tell you whether your machining is acceptable or not. To measure the actual value of machining, you can use a roughness gauge.

This is the end of the video. I hope that you have learned from this video. In the next video, I will explain to you gasket-related questions. So keep on checking my youtube channel for new videos.

Visit my website hardhatengineer.com for free study materials, and don’t forget to subscribe to my channel to get regular updates on new videos. Please like and share my video with your friends. If you want to request a video, please write in the comment. See you soon. Goodbye, take care.

Are You Piping Components Master?