In this video, you will learn about the fundamentals of pipes used in the process piping of oil and gas industries. You will learn different types of pipes, common materials, and ASTM grades.

You will also learn about NPS & Schedule numbers that are used to define pipe size and thickness.

You will also learn about double random & single random pipe length and what the difference is between a small bore and a large bore pipe.

Please subscribe to my channel to get regular updates on new videos and also like and share my video with your friends. If you have any questions or want to know something different, please write in the comment below. If you are a first-time visitor, I have a gift at the end of the video, so please do watch till finished.

What is Pipe?

The pipe is a straight pressure-tight cylindrical hollow used in the piping system to transport liquid, gas, and sometimes solids.

Different types of pipes are used in different design conditions, considering technical and commercial parameters. For small & medium size requirements, seamless pipes are more popular whereas, for larger diameters, welded pipes are more economical.

Pipes are mainly classified into two main categories seamless and welded. Welded pipes are further classified based on the method of welding. There are two ways to weld pipe 1st with filler metal and 2nd is without filler metal.

SAW process is with filler metal welding, whereas ERW and HFW are no filler welding methods to weld the pipe. EFW pipe can be welded with or without filler material. SAW pipes are further classified as straight seam and spiral seam pipes.

Straight seam pipes are also known as L-SAW or long seam SAW pipes. A medium diameter straight SAW pipe has a single seam, whereas a large diameter pipe has a two weld seam.

ASME B31.3 provides the list of materials that can be used in Process Piping. ASME B31.3 covers Carbon steel, Low alloy steel, Stainless steel, Exotic material, such as Titanium, Copper, Nickel, and its alloy, and Non-metal such as PVC, HDPE, GRE/GRP, etc.

Here in this table, you can see that carbon steel material is used up to 425-degree centigrade, and above that, low alloy steel is used. For corrosive services, stainless steel materials are used.

For low-temperature service, LTCS materials are used. Non-metallic materials such as GRE GRP pipes are used in seawater and other low-pressure but corrosive services.

Lined and Clade Pipe

With the increase in technological advances lined and clade, materials are getting popular in Process industries. When combining two materials, we can get the advantage of the two materials at a low cost.

The lined pipe has a Mechanical bonding between pipe and line material.

By applying lined material to carbon steel pipe, we can get benefit from the anti-corrosion property of lined material and the strength of carbon steel.

Commonly used lined materials are PTFE, Rubber, Glass, and FRP (Fiber-reinforced plastic)

Clade Pipe – as against to mechanical bond between pipe & lined material, a clad pipe has a Metallurgical bond between pipe and cladding material.

The cladding is done by an explosive bonding process or by welding clad material on the pipe, which is also known as overly.

High-strength carbon steel material is clad with high corrosion-resistant stainless still material to achieve cost benefits.

Pipe FIttings Quiz – Test yourself, Take This Quiz

Unlock New Skills with Our Best Selling Online Courses

Pipe Size NPS, NB, and DN

Ok, now let’s discussed pipe size. Pipe size is defined in either NPS, NB, or DN.

NPS – Nominal Pipe Size

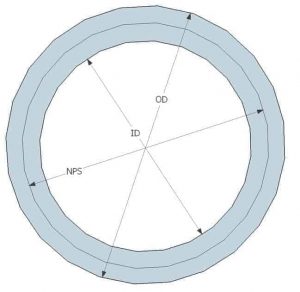

All American standards used NPS designation to define pipe size. This is a modern derivation of earlier IPS – Iron Pipe Size. NPS is not an OD or ID of the pipe it is in-between the outer and the inner diameter of the pipe but not exactly in the middle of it.

For example, NPS 2 size pipe’s outside diameter is 60 mm or 2.375 inches. NPS 12 and the smaller pipe have an outside diameter greater than the designated size, and for NPS 14 and above, the outside diameter is the same as the designated size in inches. That means 16” pipe OD is 16”.

NB – Nominal Bore

This is the European equivalent of NPS. In this standard pipe, sizes are mentioned in millimeters.

DN – Diameter nominal

This is the German equivalent of NPS. In this standard also, pipe sizes are mentioned in millimeters.

Here you can see the Pipe cross-section clarifying ID/OD & NPS. Pipe outside diameter is standardized hence ID will change with changes in Pipe thickness.

Small Vs. Large Bore Pipe

In the project, you will come across terms such as small Bore & large bore. Do you know what is Small Bore and Large Bore Pipe?

In general, Pipes having a size range of ½” – 1 ½ ” is called small-bore. Pipes with a size range 2” & above are called a big bore. This may vary slightly depending on the company to company, but at most, it is the same. As some companies refer up to 2 1/2” small bore and above that large bore.

- Standard carbon and alloy steel pipe dimensions in the range of 1/8” to 80” covers in ASME B36.10.

- The standard stainless steel pipe dimension in the range of 1/8” to 30” covers ASME B36.19.

Pipe length is mentioned in either meter or feet. During production, pipes are not manufactured in the same lengths, and during the construction of the process plants, you require various lengths of pipe. To address this issue, pipe standard has defined pipe lengths in single random and double random categories.

Single Vs. Double Random Pipe

The single random pipe comes in

4.8 m to 6.7 m in lengths, with 5% of lengths in between 3.7 to 4.8 m

The double random pipe has a

a minimum average of 10.7 m and a minimum length of 4.8 m with 5 % of lengths in between 4.8 m to 10.7 m, Maximum size is by default restricted due to transport constraints.

You cannot transport a very long pipe via regular means. However, you can order Fixed length pipe, but it will cost you more.

Based on your construction requirements, you can choose the pipe lengths.

Pipe Thickness and Schedule Number

Pipe Thickness is expressed in Schedule number (common schedule nos. are 5, 10, 20, 30, 40, 60, 80, 100, 120, 140, 160). If you want thicker pipe than Sch 160, you have to mention it in your specification or PO.

Pipe Thickness is also expressed as STD, extra strong-XS, double extra strong-XXS. If you refer to ASME B16.10, which gives a standard dimension for carbon steel pipe, you will find the corresponding schedule no. to this standard schedule no. Higher the schedule no. higher the thickness of the pipe and lower the Insider Diameter.

What is Schedule No?

A schedule number is an approximate value of the equation = 1000 P/S

P is the service pressure in (psi)

S is the allowable stress in (psi)

As said earlier, the outside diameter of each pipe size is standardized. Therefore, the inside diameter depends on the scheduled number of pipes.

ASME B36.10 provides standard dimension requirements for Welded & Seamless wrought iron pipes.

The thickness of the ss pipe is also expressed in Schedule number. However, there are only four scheduled nos. mentioned in ASME B36.19 that is (5S, 10S, 40S, 80S)

Schedule no with S suffix is used for SS pipe as per ASME B36.19,

So, please remember schedules no. 10 and 10S are not the same and have different thicknesses & materials.

Pipe Ends Type

A pipe can be a

Plain end – plain end pipes are used with socket-type weld fittings

Beveled end – this kind of end users when butt-type weld fittings are used

Threaded end pipe used with threaded connections in the piping system

There is Special end such as socket & spigot with O-ring type gaskets are also available

Please subscribe to my channel to get regular updates on new videos and also like and share my video with your friends. If you want to request a video, please write in the comment below. And don’t forget to check the free piping component guide by visiting my website. See you soon, goodbye, take care.

To subscribe to my YouTube Channel, click: https://goo.gl/LSMDCV

Are You Piping Components Master?