In this video, you will learn about pipe fitting hydro-testing requirements and proof tests, also known as burst tests.

Hydrotest for Pipe Fittings

- Hydrostatic Test or hydro test is not required for pipe fittings unless specifically requested by the purchaser. Code mandates that fittings be able to withstand the pressure required by the applicable Piping Code. But all manufacturer has to prove their design that fittings can withstand rated pressure by the proof test. I will explain to you the proof test in a minute.

- I have seen that most purchasers mandate that a hydro-tested pipe shall be used to manufacture fittings, and the weld seam is subjected to 100% radiography to ensure the soundness of the weld and, therefore, no lake from the weld in the future.

Pipe FIttings Quiz – Test yourself, Take This Quiz

Unlock New Skills with Our Best Selling Online Courses

What is the Proof Test?

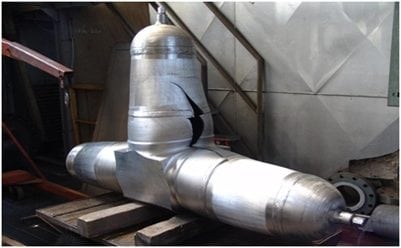

To qualify the design of the pipe fitting, the manufacturer performed various tests, including a burst test, to ensure that the design would meet all the standard & code requirements. In this test, a pipe & fittings are welded, and a dummy pipe spool is prepared.

This pipe spool is then pressurized to pre-define calculated burst test pressure. and in some cases, they keep pressurizing the fitting till it actually bursts. But it is very dangerous, so nowadays, they use a finite element method or similar computerized program to establish the design.

If the fittings withstand the test, all future products manufactured using that design will consider safe to use.

Lap joint stubs are exempt from the proof test because they are used with flange assembly and design, considering applicable pressure-temperature ratings used to design flanges.

I hope you have enjoyed the video. Don’t forget to subscribe to my channel to get regular updates on new videos and also like and share my video with your friends. If you want to request a video, please write in the comment below. And don’t forget to check the free piping component guide by visiting my website. See you soon, goodbye, take care.

Are You Piping Components Master?