Pipe Schedule Number is the standard method to define the thickness of the pipes used in Process Plants.

Standardization of wrought steel Pipe schedule and pipe sizes began with the mass production era. At that time, pipes were available in only three sizes standard weight (STD), extra-strong (XS), and double extra-strong (XXS), based on the iron pipe size (IPS) system.

With the modernizing of various industries and the use of pipes in different pressure and temperature conditions, three sizes are insufficient to meet the requirement. This will result in the concept of the schedule number that combines wall thickness and diameter of the pipe.

In current practice, pipe size defines by two sets of number

- Pipe bore/nominal diameter

- The pipe schedule is nothing but the wall thickness of the pipe.

What is Nominal Pipe Size?

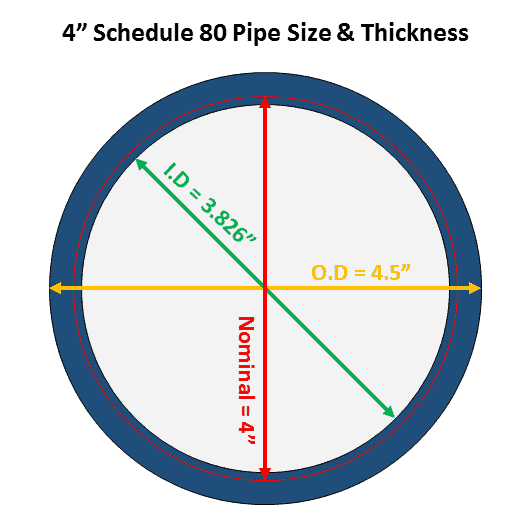

Nominal pipe size (NPS) is the number that defines the size of the pipe. For example, when you say 6” pipe, the 6” is the nominal size of that pipe. However, for the pipe sizes, NPS 14 and above Outside Diameter is the same as NPS. To understand this concept, you have to learn the way pipes are manufactured.

Manufacturing of NPS ⅛ (DN 6) to NPS 12 (DN 300) pipe is based on fixed outside diameter (OD). So, with any increase in wall thickness, the pipe’s inside diameter (ID) decreases. So the NPS will be somewhere in-between OD & ID of the pipe.

Manufacturing of NPS 14 (DN350) and above pipe OD is corresponding to the Nominal Size of a pipe. With the below example, you have more clarity of the concept.

| OD in Inch | OD in mm | Thickness in Inch | Thickness in mm | ID in Inch | ID in mm |

|---|---|---|---|---|---|

| For NPS 2 Schedule 40 pipe | |||||

| 2.375 | 60.3 | 0.154 | 3.91 | 2.067 | 52.5 |

| For NPS 14 Schedule 40 pipe | |||||

| 14 | 350 | 0.438 | 11.13 | 13.124 | 333.3 |

From the above table, you can see that for NPS 2, Pipe ID is near to pipe NPS, and for NPS 14, pipe OD is the same as NPS.

You can easily convert inch dimension to mm by multiplying it by 25.4 and rounding as follow;

- Outside diameter above 16 inches rounded to nearest 1 mm

- Outside diameter 16 inches and below rounded to nearest 0.1 mm

- Pipe wall thickness is rounded to the nearest 0.01 mm

What is Pipe NB (Nominal Bore)?

NPS is frequently referred as an NB (Nominal Bore). As such, there is no difference between NB and NPS. NB is also an American way to refer to pipe dimensions. I have also seen that when pipe dimensions are shown in mm (DN) people refer to pipe sizes in NB. So when someone says 25nb pipe or 50nb pipe, basically they are talking about DN.

What is DN (Diameter Nominal) Pipe Size?

DN or Diameter Nominal is an International designation (SI or Matric Designator) and a European NPS equivalent to show pipe sizes. Here, you have to note that DN shows pipe sizes differently than NPS.

2” pipe is simply mentioned as DN 50. You can get any NPS to DN by multiplying it by 25. Check the below table for easy understanding. There is no change in other dimensions when you use DN.

| Nominal Pipe Size | Diameter Nominal | Nominal Pipe Size | Diameter Nominal |

|---|---|---|---|

| NPS (inches) | DN (mm) | NPS (inches) | DN (mm) |

| 1/8 | 6 | 20 | 500 |

| 1/4 | 8 | 22 | 550 |

| 3/8 | 10 | 24 | 600 |

| 1/2 | 15 | 26 | 650 |

| 3/4 | 20 | 28 | 700 |

| 1 | 25 | 30 | 750 |

| 1 ¼ | 32 | 32 | 800 |

| 1 ½ | 40 | 36 | 900 |

| 2 | 50 | 40 | 1000 |

| 2 ½ | 65 | 42 | 1050 |

| 3 | 80 | 44 | 1100 |

| 3 ½ | 90 | 48 | 1200 |

| 4 | 100 | 52 | 1300 |

| 5 | 125 | 56 | 1400 |

| 6 | 150 | 60 | 1500 |

| 8 | 200 | 64 | 1600 |

| 10 | 250 | 68 | 1700 |

| 12 | 300 | 72 | 1800 |

| 14 | 350 | 76 | 1900 |

| 16 | 400 | 80 | 2000 |

| 18 | 450 | Based on ASME B36.10 | |

From this table, you can see that initially pipe size increases by ¼ than ½ and then by 1”. From 6” to 42”, it increases by 2” step and after that in 4”.

What is Pipe Schedule?

The pipe schedule is the way pipe wall thickness is mentioned. To simplify the ordering of the pipe ASME committee has developed Schedule Number, which is based on modified Barlow’s wall thickness formula.

Definition of Schedule Number: The schedule number indicates an approximate value of the expression 1000 x P/S where P is the service pressure and S is the allowable stress, both expressed in pounds per square inch.

You can see the pipe schedule calculation formula below;

Schedule number = P/S

- P is the service pressure in (psi)

- S is the allowable stress in (psi)

So, what does schedule 40 means?

Schedule 40 is nothing but a pipe thickness designator. In simple words, you can say that for a given material, schedule 40 pipes can withstand a certain amount of pressure.

Now, can you tell me which is thicker, schedule 40 or 80 pipes?

Schedule 80 pipe is thicker than schedule 40 pipe. Look at the above formula of schedule number; allowable stress for material at a given temperature is fixed. That means with an increase in service pressure schedule number will increase, which is a pipe wall thickness designator.

Piping Component Quiz – Test yourself, Take This Quiz

Unlock New Skills with Our Best Selling Online Courses

Pipe Schedule for Stainless Steel Pipe

The cost of stainless steel pipe is much higher than carbon steel pipe. Due to corrosion resistance properties of stainless steel, advancement of high alloy stainless steel, and fusion welding, less thickness pipe can work satisfactorily without fear of early failure.

To reduce material costs, ASME has introduced different schedule numbers for stainless steel pipes and fittings. Under ASME B36.19 Schedule no. with the “S” suffix is introduced for SS pipe. Example- 10S

Standard Pipe Schedule as per ASME B36.10 and B36.19

Refer to the table given below that summarizes the available schedule numbers for carbon steel and stainless steel pipe based on ASME B36.10 and B36.19.

| For Carbon Steel and Wrought iron Pipe as per ASME B36.10 | 5, 10, 20, 30, 40, 60, 80, 100, 120, 140, 160, STD, XS, XXS |

|---|---|

| For Stainless Steel Pipe as per ASME B36.19 | 5S, 10S, 40S, 80S |

Please note the following;

- STD (Standard) and Schedule 40 have the same thickness up to NPS 10 (DN 250)

- Above NPS 10 STD has a wall thickness of 3/8 in. (9.53 mm)

- XS has the same thickness as Schedule 80 for up to NPS 8 (DN 200)

- Above NPS 8 XS has a wall thickness of ½ in. (12.5 mm)

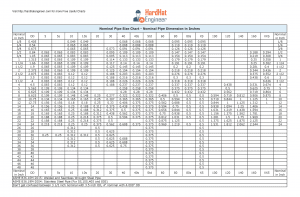

NPS Pipe Size Chart in Inch

| Nominal Pipe Size Chart – In Inches | ||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Size in Inch | OD | 5 | 5s | 10 | 10s | 20 | 30 | 40 | 40s | Std | 60 | 80 | 80s | XS | 100 | 120 | 140 | 160 | XXS | Size in Inch |

| 1/8 | 0.405 | 0.049 | 0.049 | 0.068 | 0.068 | 0.068 | 0.095 | 0.095 | 0.095 | 1/8 | ||||||||||

| 1/4 | 0.54 | 0.065 | 0.065 | 0.088 | 0.088 | 0.088 | 0.119 | 0.119 | 0.119 | 1/4 | ||||||||||

| 3/8 | 0.675 | 0.065 | 0.065 | 0.073 | 0.091 | 0.091 | 0.091 | 0.126 | 0.126 | 0.126 | 3/8 | |||||||||

| 1/2 | 0.84 | 0.065 | 0.065 | 0.083 | 0.083 | 0.095 | 0.109 | 0.109 | 0.109 | 0.147 | 0.147 | 0.147 | 0.188 | 0.294 | 1/2 | |||||

| 3/4 | 1.05 | 0.065 | 0.065 | 0.083 | 0.083 | 0.095 | 0.113 | 0.113 | 0.113 | 0.154 | 0.154 | 0.154 | 0.219 | 0.308 | 3/4 | |||||

| 1 | 1.315 | 0.065 | 0.065 | 0.109 | 0.109 | 0.114 | 0.133 | 0.133 | 0.133 | 0.179 | 0.179 | 0.179 | 0.25 | 0.358 | 1 | |||||

| 1 1/4 | 1.66 | 0.065 | 0.065 | 0.109 | 0.109 | 0.117 | 0.14 | 0.14 | 0.14 | 0.191 | 0.191 | 0.191 | 0.25 | 0.382 | 1 1/4 | |||||

| 1 1/2 | 1.9 | 0.065 | 0.065 | 0.109 | 0.109 | 0.125 | 0.145 | 0.145 | 0.145 | 0.2 | 0.2 | 0.2 | 0.281 | 0.4 | 1 1/2 | |||||

| 2 | 2.375 | 0.065 | 0.065 | 0.109 | 0.109 | 0.125 | 0.154 | 0.154 | 0.154 | 0.218 | 0.218 | 0.218 | 0.344 | 0.436 | 2 | |||||

| 2 1/2 | 2.875 | 0.083 | 0.083 | 0.12 | 0.12 | 0.188 | 0.203 | 0.203 | 0.203 | 0.276 | 0.276 | 0.276 | 0.375 | 0.552 | 2 1/2 | |||||

| 3 | 3.5 | 0.083 | 0.083 | 0.12 | 0.12 | 0.188 | 0.216 | 0.216 | 0.216 | 0.3 | 0.3 | 0.3 | 0.438 | 0.6 | 3 | |||||

| 3 1/2 | 4 | 0.083 | 0.083 | 0.12 | 0.12 | 0.188 | 0.226 | 0.226 | 0.226 | 0.318 | 0.318 | 0.318 | 0.636 | 3 1/2 | ||||||

| 4 | 4.5 | 0.083 | 0.083 | 0.12 | 0.12 | 0.188 | 0.237 | 0.237 | 0.237 | 0.337 | 0.337 | 0.337 | 0.438 | 0.531 | 0.674 | 4 | ||||

| 5 | 5.563 | 0.109 | 0.109 | 0.134 | 0.134 | 0.258 | 0.258 | 0.258 | 0.375 | 0.375 | 0.375 | 0.5 | 0.625 | 0.75 | 5 | |||||

| 6 | 6.625 | 0.109 | 0.109 | 0.134 | 0.134 | 0.28 | 0.28 | 0.28 | 0.432 | 0.432 | 0.432 | 0.562 | 0.719 | 0.864 | 6 | |||||

| 8 | 8.625 | 0.109 | 0.109 | 0.148 | 0.148 | 0.25 | 0.277 | 0.322 | 0.322 | 0.322 | 0.406 | 0.5 | 0.5 | 0.5 | 0.594 | 0.719 | 0.812 | 0.906 | 0.875 | 8 |

| 10 | 10.75 | 0.134 | 0.134 | 0.165 | 0.165 | 0.25 | 0.307 | 0.365 | 0.365 | 0.365 | 0.5 | 0.594 | 0.5 | 0.5 | 0.719 | 0.844 | 1 | 1.125 | 1 | 10 |

| 12 | 12.75 | 0.156 | 0.156 | 0.18 | 0.18 | 0.25 | 0.33 | 0.406 | 0.375 | 0.375 | 0.562 | 0.688 | 0.5 | 0.5 | 0.844 | 1 | 1.125 | 1.312 | 1 | 12 |

| 14 | 14 | 0.156 | 0.156 | 0.25 | 0.188 | 0.312 | 0.375 | 0.438 | 0.375 | 0.375 | 0.594 | 0.75 | 0.5 | 0.5 | 0.938 | 1.094 | 1.25 | 1.406 | 14 | |

| 16 | 16 | 0.165 | 0.165 | 0.25 | 0.188 | 0.312 | 0.375 | 0.5 | 0.375 | 0.375 | 0.656 | 0.844 | 0.5 | 0.5 | 1.031 | 1.219 | 1.438 | 1.594 | 16 | |

| 18 | 18 | 0.165 | 0.165 | 0.25 | 0.188 | 0.312 | 0.438 | 0.562 | 0.375 | 0.375 | 0.75 | 0.938 | 0.5 | 0.5 | 1.156 | 1.375 | 1.562 | 1.781 | 18 | |

| 20 | 20 | 0.188 | 0.188 | 0.25 | 0.218 | 0.375 | 0.5 | 0.594 | 0.375 | 0.375 | 0.812 | 1.031 | 0.5 | 0.5 | 1.281 | 1.5 | 1.75 | 1.969 | 20 | |

| 22 | 22 | 0.188 | 0.188 | 0.25 | 0.218 | 0.375 | 0.5 | 0.375 | 0.875 | 1.125 | 0.5 | 1.375 | 1.625 | 1.875 | 2.125 | 22 | ||||

| 24 | 24 | 0.218 | 0.218 | 0.25 | 0.25 | 0.375 | 0.562 | 0.688 | 0.375 | 0.375 | 0.969 | 1.219 | 0.5 | 0.5 | 1.531 | 1.812 | 2.062 | 2.344 | 24 | |

| 26 | 26 | 0.312 | 0.5 | 0.375 | 0.5 | |||||||||||||||

| 28 | 28 | 0.312 | 0.5 | 0.625 | 0.375 | 0.5 | ||||||||||||||

| 30 | 30 | 0.25 | 0.25 | 0.312 | 0.312 | 0.5 | 0.625 | 0.375 | 0.5 | |||||||||||

| 32 | 32 | 0.312 | 0.5 | 0.625 | 0.688 | 0.375 | 0.5 | |||||||||||||

| 34 | 34 | 0.312 | 0.5 | 0.625 | 0.688 | 0.375 | 0.5 | |||||||||||||

| 36 | 36 | 0.312 | 0.5 | 0.625 | 0.75 | 0.375 | 0.5 | |||||||||||||

| 38 | 38 | 0.375 | 0.5 | |||||||||||||||||

| 40 | 40 | 0.375 | 0.5 | |||||||||||||||||

| 42 | 42 | 0.375 | 0.5 | |||||||||||||||||

| 44 | 44 | 0.375 | 0.5 | |||||||||||||||||

| 46 | 46 | 0.375 | 0.5 | |||||||||||||||||

| 48 | 48 | 0.375 | 0.5 | |||||||||||||||||

| Size in Inch | OD | 5 | 5s | 10 | 10s | 20 | 30 | 40 | 40s | Std | 60 | 80 | 80s | XS | 100 | 120 | 140 | 160 | XXS | Size in Inch |

| ASME B36.10M-2015: Welded and Seamless Wrought Steel Pipe | ||||||||||||||||||||

| ASME B36.19M-2004: Stainless Steel Pipe (For 5S,10S,40S and 80S) | ||||||||||||||||||||

| Don’t get confused between 3 1/2 inch nominal with 3.5 inch OD, 4″ nominal with 4.000″ OD | ||||||||||||||||||||

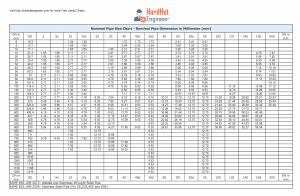

NPS Pipe Size Chart in MM

| Nominal Pipe Size Chart – Nominal Pipe Dimension in Millimeter (mm) | ||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DN in mm | OD | 5 | 5s | 10 | 10s | 20 | 30 | 40 | 40s | Std | 60 | 80 | 80s | XS | 100 | 120 | 140 | 160 | XXS | DN in mm |

| 6 | 10.3 | 1.24 | 1.24 | 1.73 | 1.73 | 1.73 | 2.41 | 2.41 | 2.41 | |||||||||||

| 8 | 13.7 | 1.65 | 1.65 | 2.24 | 2.24 | 2.24 | 3.02 | 3.02 | 3.02 | |||||||||||

| 10 | 17.1 | 1.65 | 1.65 | 1.85 | 2.31 | 2.31 | 2.31 | 3.2 | 3.2 | 3.2 | ||||||||||

| 15 | 21.3 | 1.65 | 1.65 | 2.11 | 2.11 | 2.41 | 2.77 | 2.77 | 2.77 | 3.73 | 3.73 | 3.73 | 4.78 | 7.47 | ||||||

| 20 | 26.7 | 1.65 | 1.65 | 2.11 | 2.11 | 2.41 | 2.87 | 2.87 | 2.87 | 3.91 | 3.91 | 3.91 | 5.56 | 7.82 | ||||||

| 25 | 33.4 | 1.65 | 1.65 | 2.77 | 2.77 | 2.9 | 3.38 | 3.38 | 3.38 | 4.55 | 4.55 | 4.55 | 6.35 | 9.09 | ||||||

| 32 | 42.2 | 1.65 | 1.65 | 2.77 | 2.77 | 2.97 | 3.56 | 3.56 | 3.56 | 4.85 | 4.85 | 4.85 | 6.35 | 9.7 | ||||||

| 40 | 48.3 | 1.65 | 1.65 | 2.77 | 2.77 | 3.18 | 3.68 | 3.68 | 3.68 | 5.08 | 5.08 | 5.08 | 7.14 | 10.16 | ||||||

| 50 | 60.3 | 1.65 | 1.65 | 2.77 | 2.77 | 3.18 | 3.91 | 3.91 | 3.91 | 5.54 | 5.54 | 5.54 | 8.74 | 11.07 | ||||||

| 65 | 73 | 2.11 | 2.11 | 3.05 | 3.05 | 4.78 | 5.16 | 5.16 | 5.16 | 7.01 | 7.01 | 7.01 | 9.53 | 14.02 | ||||||

| 80 | 88.9 | 2.11 | 2.11 | 3.05 | 3.05 | 4.78 | 5.49 | 5.49 | 5.49 | 7.62 | 7.62 | 7.62 | 11.13 | 15.24 | ||||||

| 90 | 101.6 | 2.11 | 2.11 | 3.05 | 3.05 | 4.78 | 5.74 | 5.74 | 5.74 | 8.08 | 8.08 | 8.08 | 16.15 | |||||||

| 100 | 114.3 | 2.11 | 2.11 | 3.05 | 3.05 | 4.78 | 6.02 | 6.02 | 6.02 | 8.56 | 8.56 | 8.56 | 11.13 | 13.49 | 17.12 | |||||

| 125 | 141.3 | 2.77 | 2.77 | 3.4 | 3.4 | 6.55 | 6.55 | 6.55 | 9.53 | 9.53 | 9.53 | 12.7 | 15.88 | 19.05 | ||||||

| 150 | 168.3 | 2.77 | 2.77 | 3.4 | 3.4 | 7.11 | 7.11 | 7.11 | 10.97 | 10.97 | 10.97 | 14.27 | 18.26 | 21.95 | ||||||

| 200 | 219.1 | 2.77 | 2.77 | 3.76 | 3.76 | 6.35 | 7.04 | 8.18 | 8.18 | 8.18 | 10.31 | 12.7 | 12.7 | 12.7 | 15.09 | 18.26 | 20.62 | 23.01 | 22.23 | |

| 250 | 273 | 3.4 | 3.4 | 4.19 | 4.19 | 6.35 | 7.8 | 9.27 | 9.27 | 9.27 | 12.7 | 15.09 | 12.7 | 12.7 | 18.26 | 21.44 | 25.4 | 28.58 | 25.4 | |

| 300 | 323.8 | 3.96 | 3.96 | 4.57 | 4.57 | 6.35 | 8.38 | 10.31 | 9.53 | 9.53 | 14.27 | 17.48 | 12.7 | 12.7 | 21.44 | 25.4 | 28.58 | 33.32 | 25.4 | |

| 350 | 355.6 | 3.96 | 3.96 | 6.35 | 4.78 | 7.92 | 9.53 | 11.13 | 9.53 | 9.53 | 15.09 | 19.05 | 12.7 | 12.7 | 23.83 | 27.79 | 31.75 | 35.71 | ||

| 400 | 406.4 | 4.19 | 4.19 | 6.35 | 4.78 | 7.92 | 9.53 | 12.7 | 9.53 | 9.53 | 16.66 | 21.44 | 12.7 | 12.7 | 26.19 | 30.96 | 36.53 | 40.49 | ||

| 450 | 457 | 4.19 | 4.19 | 6.35 | 4.78 | 7.92 | 11.13 | 14.27 | 9.53 | 9.53 | 19.05 | 23.83 | 12.7 | 12.7 | 29.36 | 34.93 | 39.67 | 45.24 | ||

| 500 | 508 | 4.78 | 4.78 | 6.35 | 5.54 | 9.53 | 12.7 | 15.09 | 9.53 | 9.53 | 20.62 | 26.19 | 12.7 | 12.7 | 32.54 | 38.1 | 44.45 | 50.01 | ||

| 550 | 559 | 4.78 | 4.78 | 6.35 | 5.54 | 9.53 | 12.7 | 9.53 | 22.23 | 28.58 | 12.7 | 34.93 | 41.28 | 47.63 | 53.98 | |||||

| 600 | 610 | 5.54 | 5.54 | 6.35 | 6.35 | 9.53 | 14.27 | 17.48 | 9.53 | 9.53 | 24.61 | 30.96 | 12.7 | 12.7 | 38.89 | 46.02 | 52.37 | 59.54 | ||

| 650 | 660 | 7.92 | 12.7 | 9.53 | 12.7 | |||||||||||||||

| 700 | 711 | 7.92 | 12.7 | 15.88 | 9.53 | 12.7 | ||||||||||||||

| 750 | 762 | 6.35 | 6.35 | 7.92 | 7.92 | 12.7 | 15.88 | 9.53 | 12.7 | |||||||||||

| 800 | 813 | 7.92 | 12.7 | 15.88 | 17.48 | 9.53 | 12.7 | |||||||||||||

| 850 | 864 | 7.92 | 12.7 | 15.88 | 17.48 | 9.53 | 12.7 | |||||||||||||

| 900 | 914 | 7.92 | 12.7 | 15.88 | 19.05 | 9.53 | 12.7 | |||||||||||||

| 950 | 965 | 9.53 | 12.7 | |||||||||||||||||

| 1000 | 1016 | 9.53 | 12.7 | |||||||||||||||||

| 1050 | 1067 | 9.53 | 12.7 | |||||||||||||||||

| 1100 | 1118 | 9.53 | 12.7 | |||||||||||||||||

| 1150 | 1168 | 9.53 | 12.7 | |||||||||||||||||

| 1200 | 1219 | 9.53 | 12.7 | |||||||||||||||||

| DN in mm | OD | 5 | 5s | 10 | 10s | 20 | 30 | 40 | 40s | Std | 60 | 80 | 80s | XS | 100 | 120 | 140 | 160 | XXS | DN in mm |

| ASME B36.10M-2015: Welded and Seamless Wrought Steel Pipe | ||||||||||||||||||||

| ASME B36.19M-2004: Stainless Steel Pipe (For 5S,10S,40S and 80S) | ||||||||||||||||||||

Nominal Pipe Size OD

| Nominal Pipe Size in Inch | Nominal Pipe Size OD in Inch | DN in mm | Nominal Pipe Size OD in mm |

|---|---|---|---|

| 1/8 | 0.405 | 6 | 10.3 |

| 1/4 | 0.54 | 8 | 13.7 |

| 3/8 | 0.675 | 10 | 17.1 |

| 1/2 | 0.84 | 15 | 21.3 |

| 3/4 | 1.05 | 20 | 26.7 |

| 1 | 1.315 | 25 | 33.4 |

| 1.25 | 1.66 | 32 | 42.2 |

| 1.5 | 1.9 | 40 | 48.3 |

| 2 | 2.375 | 50 | 60.3 |

| 2.5 | 2.875 | 65 | 73 |

| 3 | 3.5 | 80 | 88.9 |

| 3.5 | 4 | 90 | 101.6 |

| 4 | 4.5 | 100 | 114.3 |

| 5 | 5.563 | 125 | 141.3 |

| 6 | 6.625 | 150 | 168.3 |

| 8 | 8.625 | 200 | 219.1 |

| 10 | 10.75 | 250 | 273.1 |

| 12 | 12.75 | 300 | 323.8 |

| 14 | 14 | 350 | 355.6 |

| 16 | 16 | 400 | 406.4 |

| 18 | 18 | 450 | 457 |

| 20 | 20 | 500 | 508 |

| 22 | 22 | 550 | 559 |

| 24 | 24 | 600 | 610 |

| 26 | 26 | 650 | 660 |

| 28 | 28 | 700 | 711 |

| 30 | 30 | 750 | 762 |

| 32 | 32 | 800 | 813 |

| 34 | 34 | 850 | 864 |

| 36 | 36 | 900 | 914 |

| 38 | 38 | 950 | 965 |

| 40 | 40 | 1000 | 1016 |

| 42 | 42 | 1050 | 1067 |

| 44 | 44 | 1100 | 1118 |

| 46 | 46 | 1150 | 1168 |

| 48 | 48 | 1200 | 1219 |

Using the formula given below, you can calculate the Pipe Inside Diameter (ID) with the help of the Outside Diameter (OD) and Thickness of the pipe.

Pipe ID = [Pipe O.D. – (2×Pipe wall thickness)]

Dimension Tolerance for Carbon Steel and Stainless Steel Pipe

Common dimension tolerances are listed in ASTM A530. However, each product has its own requirements, and when given in that specification, that will govern above and over the A530.

| Description | Size | Over | Under |

|---|---|---|---|

| Weight | NPS 12 (DN 300) and under | 10% | 3.50% |

| Weight | NPS 14 (DN 350) and above (Note-1) | 10% | 5% |

| Wall Thickness | |||

| Seamless and Welded Pipe | 1⁄8 to 2 ½, incl., all t/D ratios (Note-2) | 20.00% | 12.50% |

| 3 to 18 incl., t/D up to 5 % incl. | 22.50% | 12.50% | |

| 3 to 18 incl., t/D > 5 % | 15.00% | 12.50% | |

| 20 and larger, welded, all t/D ratios (Note-3) | 17.50% | 12.50% | |

| 20 and larger, seamless, t/D up to 5 % incl. | 22.50% | 12.50% | |

| 20 and larger, seamless, t/D > 5 % | 15.00% | 12.50% | |

| Forged and Bored Pipe | 1/8 in.(3.2mm) | Nil | |

| Cast Pipe | 1/6 in.(1.6mm) | Nil | |

| Inside Diameter for Cast Pipe | Nil | 1⁄16 in. (1.6 mm) | |

| Outside Diameter (Note-4) | |||

| DiameterOutside | 1⁄8 to 11⁄2, incl | 1⁄64 in. (0.4mm) | 1/32 in. (0.8mm) |

| Over 1 ½ to 4, incl | 1/32 in. (0.8mm) | 1/32 in. (0.8mm) | |

| Over 4 to 8, inc | 1/16 in. (1.6mm) | 1/32 in. (0.8mm) | |

| Over 8 to 18, incl | 3/32 in. (2.4mm) | 1/32 in. (0.8mm) | |

| Over 18 to 26, incl | 1/8 in. (3.2mm) | 1/32 in. (0.8mm) | |

| Over 26 to 34, incl | 5/32 in. (4.0mm) | 1/32 in. (0.8mm) | |

| Over 34 | 3/8 in. (4.8mm) | 1/32 in. (0.8mm) | |

| As per ASTM A530/A530M-12 and ASTM A999/A999M-15 | |||

- Note-1: Pipes of NPS 4 (DN 100) and smaller may be weighed in lots; pipes in sizes larger than NPS 4 (DN 100) shall be weighed separately.

- Note-2: t = Nominal wall thickness. D = Outside diameter.

- Note-3: For welded pipe, the weld area shall not be limited by the over tolerance.

- Note-4: For thin-wall pipe, the ovality in any one cross-section shall not exceed 1.5 % of the specified outside diameter.

Are You Piping Components Master?