To fully understand pipe class and piping specification, you must know the basics of piping.

Pipe covers a very large part of any process plant. If you look at the Oil Exploration platform, Refinery, and Petrochemical complex, one thing that catches your attention is a complex network of piping. Piping is used to transport various process materials from one piece of equipment to another. But why?

A process Plant is a place where a series of activities are performed in particular order to convert raw material into a useful product. Interconnected pipe and pipe components are used to transport raw material, intermediated product, and final product to the desired location.

What is Pipe?

The pipe is a straight pressure-tight cylindrical hollow used in the piping system to transport liquid, gas, and sometimes solids.

Classification of Pipes (Types of Pipe Used in Oil and Gas)

Different types of pipes are used in various design conditions, considering technical and commercial parameters. For small & medium size requirements, seamless pipes are more popular whereas, for larger diameters, welded pipes are more economical.

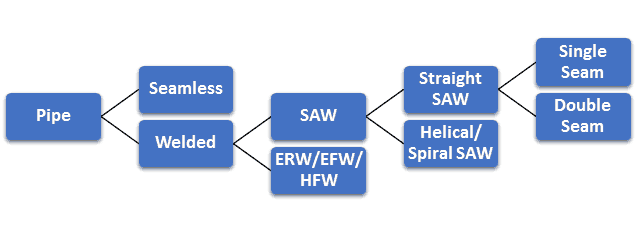

Based on the way pipe manufacturing, Pipes are mainly classified into two categories seamless and welded. Welded pipes are further classified based on the method of welding. There are two ways to weld pipe 1st with filler metal and 2nd is without filler metal.

The submerged Arc Welding process is with filler metal welding, whereas ERW/EFW and HFW are no filler welding methods to weld the pipe. SAW pipes are further classified as straight seam and spiral seam pipes. Straight seam pipes are also known as L-SAW or long seam SAW pipes. Medium diameter straight SAW pipe has a single seam, whereas a large-diameter pipe has a two-weld seam.

Check the image below for easy understanding.

What is Pipe Class?

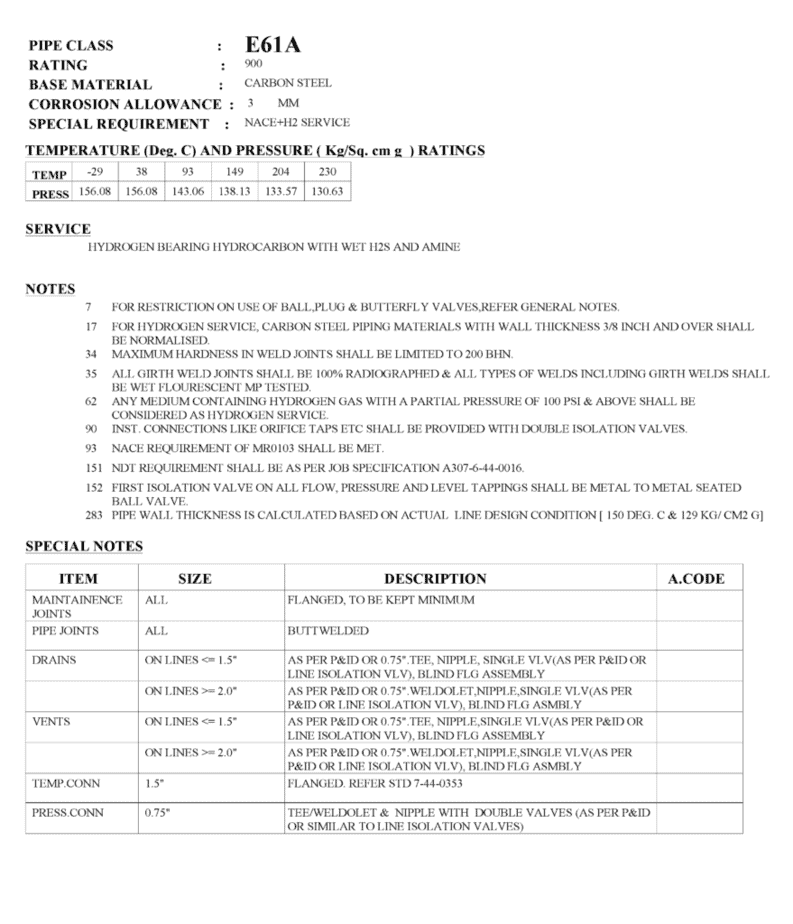

Piping class or Pipe Class is a document that specifies the type of the components such as a type of pipe, schedule, material, flange ratings, branch types, valve types and valve trim material, gasket, and all the other components specific requirements to be used for different fluids under different operating conditions in a plant.

Pipe class is developed considering Operating Pressure, temperature, and corrosive environment. Different material specifications are segregated into separate “Piping Class”. The pipe class is part of the Piping specification.

Shortcode is used to cover all the information applicable to the given pipe class. This pipe class is also included in the line number so that field construction engineers can easily identify the material required.

Piping Component Quiz – Test yourself, Take This Quiz

Unlock New Skills with Our Best Selling Online Courses

Check the link for an example of a piping class specification.

You can watch this video, where I have explained the above Pipe class in more detail.

What are the piping Specifications?

Piping Specifications are technical documents that are generated by private companies to address additional requirements applicable to a specific product or application.

Piping Specs provides specific/additional requirements for the materials, components, or services that are beyond the code and standard requirements. For Example, if you want an A106 Gr B pipe with Maximum carbon of 0.23% against standard requirements of 0.3% Max, you must be specified this requirement in your purchase specification.

Why did Specification require?

- It allows a purchaser to include special requirements as per design and service conditions.

- It also allows customization of the product.

- Please note requirements in the specification is Must meet requirements.

Normally, oil & gas facilities generate their own specification during the FEED stage, which is front-end engineering and design, or sometimes uses readily available specifications from well-established companies such as Shell, Bechtel, EIL, and chevron.

What are Piping Components?

Piping Components are mechanical elements suitable for joining or assembling into a pressure-tight fluid-containing piping system. Components include pipes, tubes, fittings, flanges, gaskets, bolt-nuts, valves, expansion joints, hose pipes, traps, strainers, separators, control valves, safety valves, blind flanges, spectacle blinds, drip rings, etc.

What is the Piping System?

Piping System can define as when piping components are joined together to perform some specific activities such as convey, distribute, mix, separate, discharge, meter, control, or stop the fluid flows is known as a piping system.

If you want to become an expert in piping components, you can buy my full course that covers all details related to piping components.

Pipe Dimension

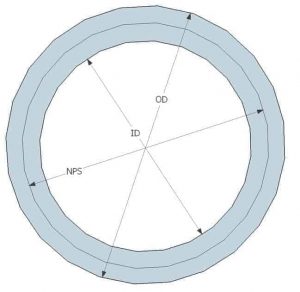

Pipe dimensions are given in size and schedule numbers. Three different terms are commonly used to define the size of the pipes.

- NPS – Nominal Pipe Size

- NB – Nominal Bore

- DN – Diameter Nominal

You can check the complete guide on Pipe Size and Schedule (Click on the link) for an in-depth understanding.

Dimensions of the pipes are covered in the following Standard

- ASME B36.10 – Welded and Seamless Wrought Steel Pipe (Carbon & Alloy Steel)

- ASME B36.19 – Stainless Steel Pipe

What are Small Bore Pipe and Large Bore Pipe?

In the project, you will come across the terms such as small Bore & big bore or large bore pipe.

Small Bore Pipe

Pipe Size up to 2” are considered small bore pipe. However, some companies consider up to 2.5″ pipe as small bore.

Large Bore Pipe (Big Bore Pipe)

Pipe Size above 2″ are considered large bore or big bore pipe

Pipe Length

The length of the pipe is mentioned in either meter or feet. During production, pipes are not manufactured in the same lengths, and during the construction of the process plants, you require varying lengths of pipes. To address this issue standard has defined pipe lengths in single random and double random categories.

Unlock New Skills with Our Best Selling Online Courses

Single random pipes

Single random pipes come in 4

Double random pipes

Double random pipes have a minimum average length of 10.7 m and a minimum length of 4.8 m, with 5 % of lengths between 4.8 m to 10.7 m

Pipe End Types

The pipes come in the following end types;

- Plain Ends

- Beveled Ends

- Threaded Ends

- Socket & Spigot Ends

Flanged Ends- Buttress Ends

Plain Ends

Plain

Advantages

- Easier Alignment than butt welding

- No weld metal intrusion into a bore

Disadvantages

- The 1/16″(1.5 mm) recess pockets liquid

- Use not permitted by code if Severe Erosion or Crevice Corrosion is anticipated.

Unlock New Skills with Our Best Selling Online Courses

Beveled Ends

Beveled end pipes are used when butt-type weld fittings are used.

Advantages

- The most practical way of joining big-bore piping

- Reliable leak-proof joint

- Joint can be radiographed

Disadvantages

- Weld intrusion will affect the flow

- End preparation is necessary

Threaded Ends

Advantages

- Easily made at the site

- It can be used where welding is not permitted due to fire hazard

Disadvantages

- Joint may leak when not properly sealed

- Use is not permitted by code if severe erosion, crevice corrosion, shock, or vibration are anticipated.

- The strength of the pipe is reduced as threads reduce the wall thickness

- Seal welding may be required

- The code specifies that seal welding shall not be considered to contribute to the strength of joints.

Are You Piping Components Master?

Socket & Spigot Ends

Socket & Spigot End pipes are generally used in the Ductile iron pipeline and non-metallic piping pipelines such as PVC, and GRE/GRP.

Advantages

- It can be easily made at the site.

- Can accept misalignment up to 10° at pipe joints.

Disadvantages

- Suitable for low-pressure applications.

- Special configuration at the pipe ends is required.

Flanged End

Flanged end pipes are used where the bolted connection is required.

Advantages

- Can be easily made at the site

- It can be used where welding is not permitted due to material properties or fire hazards.

- Dismantling is very easy

Disadvantages

- It is a point of potential leakage

- It cannot be used when piping is subjected to high bending moment.

Buttress Ends

Buttress Ends are used in glass piping and are joined by bolting with the use of backing flanges. This joint connection is not capable of holding high pressure.

Unlock New Skills with Our Best Selling Online Courses

Don’t forget to subscribe.