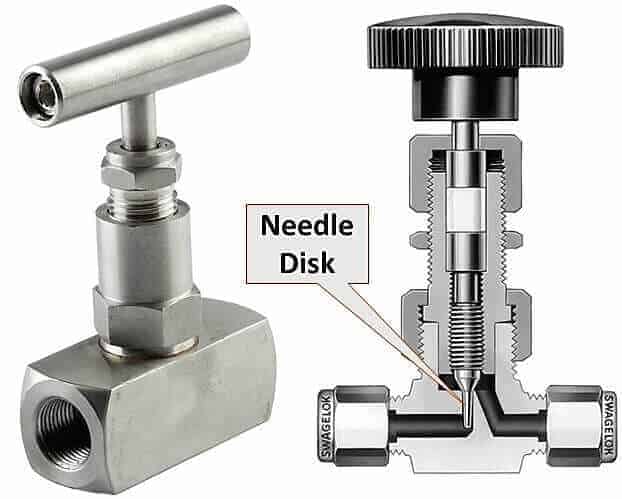

A needle valve is a manual valve used where continuous flow throttling is required for regulation. Needle valves are similar to the globe valve in design, with the biggest difference being the sharp needle-like disk.

Needle valves are designed to give very accurate flow control in small diameter piping systems. They get their name from their sharp-pointed conical disc and matching seat.

Image – Swagelok

Unlock New Skills with Our Best Selling Online Courses

Fluid flowing through the valve turns 90 degrees and passes through an orifice. Due to needle shape disk, a certain portion of the disk will pass through the seat opening before the disk comes in contact with the seat, which has to match the tapered design as a disk. This arrangement permits a very gradual increase or decrease in the size of the opening.

The needle valve has a forged and machined body. This body can be of forged carbon steel or stainless steel, depending on the requirements of the services. A seat can be a soft, metal, or composite, same as a globe valve. Normally needle valves are used in smaller sizes and are provided with either screwed or socket weld end.

All the aspects of a needle valve are the same as a global valve except its size and pointed needle-like disk. You can refer to a globe valve for more detail.

Valve Quiz – Test yourself, Take This Quiz

Unlock New Skills with Our Best Selling Online Courses

Needle Valve Application

- All field analog instruments are fitted with a needle valve to control flow entry, where sudden surges of fluid under pressure can damage the instruments.

- Needle valves can be used in situations where the flow must stop gradually and in the application where precise adjustments of flow are required or where a small flow rate is desired, such as sample points in the piping.

- Needle valves can be used as both on/off and throttle valves

- Used in all industries for controlling and metering fluid applications such as steam, air, gas, oil, water, or other non-viscous liquids.

Click here to learn about Other Types of Valve.

Unlock New Skills with Our Best Selling Online Courses