What is Latrolet?

Latrolet is a type of self-reinforced branch fitting developed by a Company called Bonney Forge. Latrolet that is used for taking branch which is not at 90 degrees to run pipe. Latrolet comes in 45°or any other special degree as required by the purchaser. End connections of a Latrolet can be butt welded, socket welded, or threaded.

Latrolet® is a Registered Trademark of Bonney Forge.

Latrolet Dimensions

Class 3000 Threaded and Socket Weld

| Class 3000 Threaded and Socket Weld | ||||

|---|---|---|---|---|

| Size | A | B | C | E |

| 1/4 | 39.69 | 59.53 | 36.51 | 39.69 |

| 3/8 | 39.69 | 59.53 | 36.51 | 39.69 |

| 1/2 | 39.69 | 59.53 | 36.51 | 39.69 |

| 3/4 | 47.63 | 69.85 | 44.45 | 48.42 |

| 1 | 55.56 | 82.55 | 53.98 | 55.56 |

| 1 1/4 | 63.50 | 97.63 | 66.68 | 74.61 |

| 1 1/2 | 69.85 | 107.16 | 76.99 | 66.68 |

| 2 | 85.73 | 138.11 | 104.78 | 80.17 |

Flange and Olet Quiz – Test yourself, Take This Quiz

Unlock New Skills with Our Best Selling Online Courses

Class 6000 Threaded and Socket Weld

| Class 6000 Threaded and Socket Weld | ||||

|---|---|---|---|---|

| Size | A | B | C | E |

| 1/4 | 39.69 | 59.53 | 36.51 | 39.69 |

| 3/8 | 39.69 | 59.53 | 36.51 | 39.69 |

| 1/2 | 47.63 | 69.85 | 44.45 | 48.42 |

| 3/4 | 55.56 | 82.55 | 53.98 | 55.56 |

| 1 | 63.50 | 92.87 | 66.68 | 62.71 |

| 1 1/4 | 69.85 | 107.16 | 76.99 | 66.68 |

| 1 1/2 | 85.73 | 138.11 | 104.78 | 80.17 |

| 2 | 85.73 | 138.11 | 104.78 | 80.17 |

Standard & XS Butt Weld

| Standard & XS Butt Weld | ||||

|---|---|---|---|---|

| Size | A | B | C | E |

| 1/4 | 33.34 | 53.18 | 36.51 | 39.69 |

| 3/8 | 33.34 | 53.18 | 36.51 | 39.69 |

| 1/2 | 34.93 | 54.77 | 36.51 | 39.69 |

| 3/4 | 42.86 | 64.29 | 44.45 | 48.42 |

| 1 | 50.01 | 76.20 | 53.98 | 55.56 |

| 1 1/4 | 57.94 | 91.28 | 66.68 | 62.71 |

| 1 1/2 | 62.71 | 100.81 | 76.99 | 66.68 |

| 2 | 80.96 | 133.35 | 104.78 | 86.52 |

| 2 1/2 | 80.17 | 131.76 | 104.78 | 80.17 |

| 3 | 96.84 | 158.75 | 126.21 | 96.04 |

| 4 | 120.65 | 198.44 | 163.51 | 115.89 |

Sch. 160 and XXS Butt Weld

| Sch. 160 and XXS Butt Weld | |||

|---|---|---|---|

| Size | A | B | C |

| 1/4 | 39.69 | 58.74 | 36.51 |

| 3/8 | 39.69 | 58.74 | 36.51 |

| 1/2 | 46.04 | 69.85 | 44.45 |

| 3/4 | 53.98 | 82.55 | 53.98 |

| 1 | 63.50 | 96.84 | 66.68 |

| 1 1/4 | 69.85 | 107.95 | 76.20 |

| 1 1/2 | 85.73 | 136.53 | 104.78 |

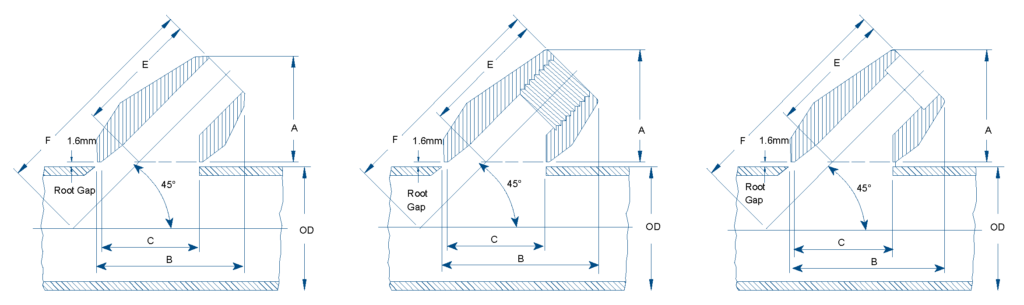

F= E + √(B² – A²) + Root Gap

Before starting your project, you can request the manufacturer for the product dimension to incorporate it into your piping ISO drawings.

Are You Piping Components Master?