Before you start learning about carbon steel, there is a term called killed carbon steel that you must know.

Fully Killed Carbon Steel Vs. Semi-killed Steel Material

During steel manufacturing, oxygen is forcibly injected into it to ledel. The oxygen combines with excess carbon and is released as a gas. Excess oxygen is, however, unavoidably left in the molten steel.

This results in the formation of oxide inclusions in the steel, or porosity, which appear upon solidification. The process of removing oxygen is known as deoxidizing. Deoxidation is achieved by adding silicon, aluminum, or other deoxidizing agents to the molten steel. The degree of deoxidation creates three different types of steel.

Killed Carbon Steel is completely deoxidized steel; no free Oxygen is left in the steel. Resulting in uniform composition and superior toughness as compared to other types.

Semi-Killed Carbon Steel is Partially deoxidized, and some free Oxygen is still left in the steel. Properties of semi-killed steel in between fully killed and rimmed steel.

Steel produced without deoxidization is known as rimmed steel, which is brittle and has poor elongation.

Only fully killed steel is used in process piping.

Cast Iron Vs. Cast Steel

There is a difference between Cast iron and Cast Steel. Let’s talk about cast iron.

Cast Iron

- Ferrous metal that contains more than or equal to 2% of Carbon by weight is cast iron.

- It is a hard and brittle material, so not useful for process piping

- However, Ductile iron pipes are widely used in water distribution networks because of their good corrosion-resistant property

- Another example of the use of cast iron is Manhole covers for the drainage

- There are other types of cast iron that are also used for different industrial purposes other than piping. Such as Grey cast iron (ASTM A48), White cast iron, Malleable iron (ASTM A47), A74, and A746.

Cast Steel

- Cast Steel is a ferrous metal that contains less than < 2% Carbon by weight.

- Cast steel is used in various casting materials used in process industries. It is used in the manufacturing of valve bodies and cast fittings.

- ASTM A216 Gr WCB and A352 Gr LCB/C is an example of cast steel grades.

Piping Component Quiz – Test yourself, Take This Quiz

Unlock New Skills with Our Best Selling Online Courses

Carbon Steel (CS)

CS also fits under the definition of cast steel, but the main difference is in the manufacturing method. It is manufactured by rolling, forging, and drawing methods.

- It is extensively used piping material in the process industry

- Iron is the main element in this type, with other elements in a non-significant amount.

- Please keep in mind that it is a type of alloy steel.

The other elements present in CS are metallic and non-metallic in nature.

- Metallic alloying elements present in CS are

- Manganese, Nickel, Chromium, Molybdenum, Vanadium, Aluminum, Copper, Silicon, etc.

- Non- Metallic alloying elements present in CS are

- Carbon, Phosphorus, Sulfur, etc.

- When added to the calculated amount, these alloying elements have different effects on the metal; some of these elements will greatly improve the material property.

Classification of carbon steel

- Based on carbon %, steel can further classify as

- Low carbon steel: in which Carbon is in the range from- 0.05% to 0.25%

- Medium Carbon Steel: in which Carbon is in the range from- 0.25% to 0.5%

- High Carbon Steel is in the range from- 0.5% to less than 2%

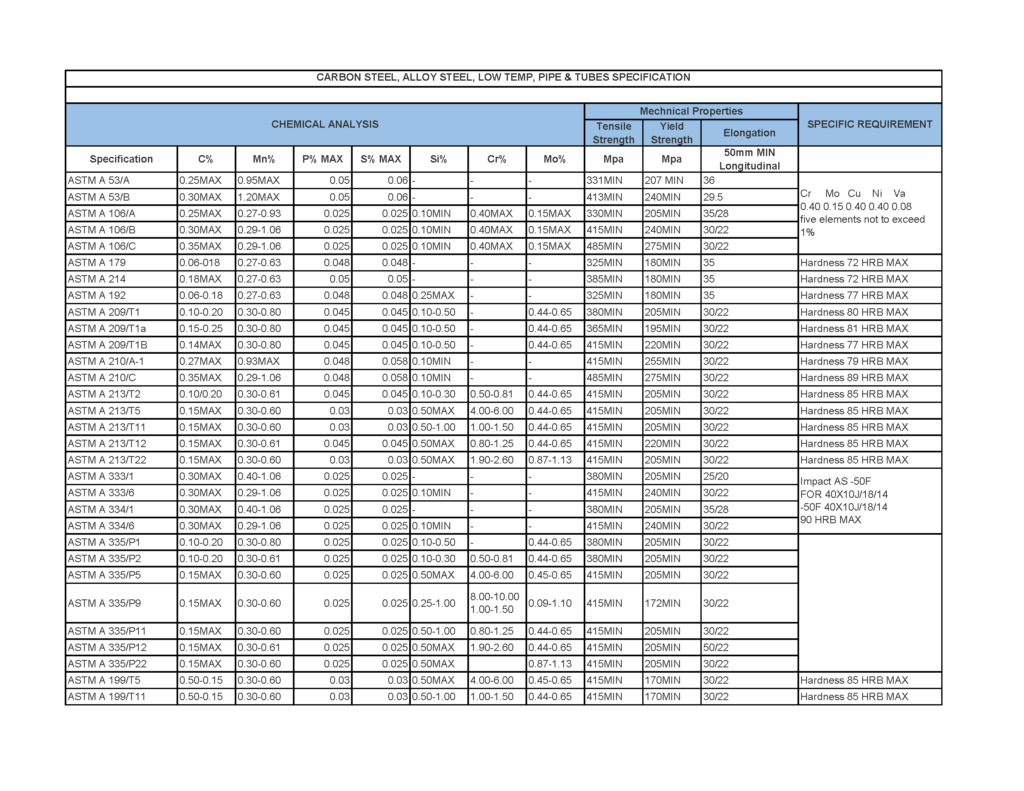

Here you can see some of the commonly used CS material grades in Process piping.

- For Pipes: ASTM A53 Gr A/B, A106 Gr A/B/C, API 5L Gr B

- For Wrought products: ASTM A234 Gr.WPA/B, A420 Gr.WPL6

- For Forged product: ASTM A105, A350 Gr LF1/LF2, A181

- ASTM A53 Pipe, Steel, Black and Hot-Dipped, Zinc-Coated, Welded, and Seamless

- ASTM A106 Seamless Carbon Steel Pipe for High-Temperature Service

- ASTM A134 Pipe, Steel, Electric-Fusion (Arc)-Welded (Sizes NPS 16 and Over)

- ASTM A135 Electric-Resistance-Welded Steel Pipe

- ASTM A139 Electric-Fusion (Arc)-Welded Steel Pipe (NPS 4 and Over)

- ASTM A182 Forged or Rolled Alloy-Steel Pipe Flanges, Forged Fittings, and Valves and Parts for High-Temperature Service

- ASTM A252 Welded and Seamless Steel Pipe Piles

- ASTM A333 Seamless and Welded Steel Pipe for Low-Temperature Service

- ASTM A335 Seamless Ferritic Alloy-Steel Pipe for High-Temperature Service

- ASTM A369 Carbon and Ferritic Alloy Steel Forged and Bored Pipe for High-Temperature Service

- ASTM A381 Standard Specification for Metal-Arc-Welded Steel Pipe for Use with High-Pressure Transmission Systems

- ASTM A426 Centrifugally Cast Ferritic Alloy Steel Pipe for High-Temperature Service

- ASTM A523 Plain End Seamless and Electric-Resistance-Welded Steel Pipe for High-Pressure Pipe-Type Cable Circuits

- ASTM A524 Seamless Carbon Steel Pipe for Atmospheric and Lower Temperatures

- ASTM A530 General Requirements for Specialized Carbon and Alloy Steel Pipe

- ASTM A691 Carbon and Alloy Steel Pipe, Electric-Fusion-Welded for High-Pressure Service at High Temperatures

- ASTM A694 Carbon and Alloy Steel Forgings for Pipe Flanges, Fittings, Valves, and Parts for High-Pressure Transmission Service

- ASTM A714 High-Strength Low-Alloy Welded and Seamless Steel Pipe

- ASTM A733 Welded and Seamless Carbon Steel and Austenitic Stainless Steel Pipe Nipples

- ASTM A865 Threaded Couplings, Steel, Black or Zinc-Coated (Galvanized) Welded or Seamless, for Use in Steel Pipe Joints

- ASTM A984 Steel Line Pipe, Black, Plain-End, Electric-Resistance-Welded

- ASTM A1005 Steel Line Pipe, Black, Plain End, Longitudinal and Helical Seam, Double Submerged-Arc Welded

- ASTM A1006 Steel Line Pipe, Black, Plain End, Laser Beam Welded

Are You Piping Components Master?