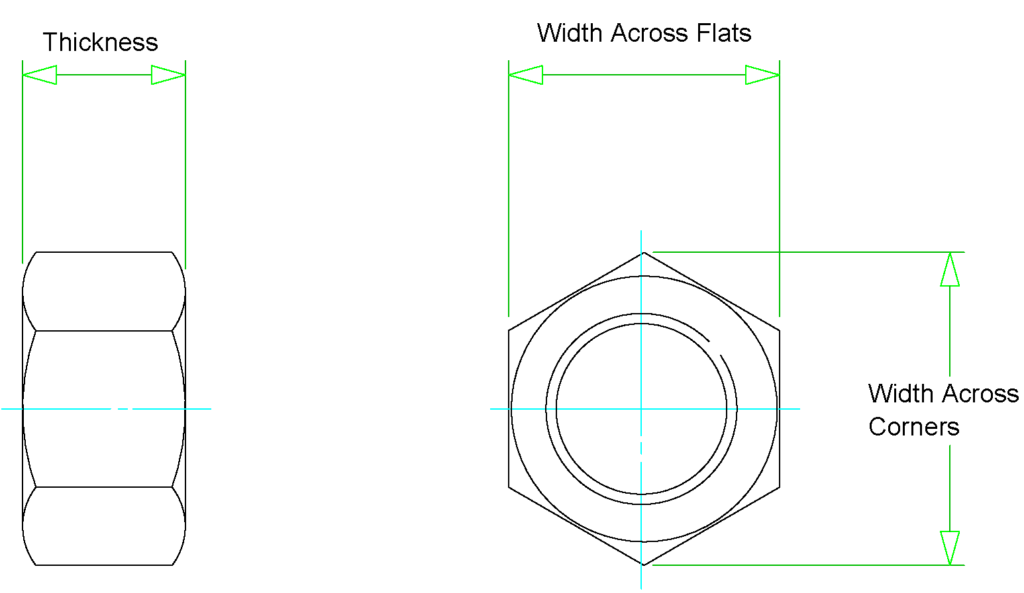

Hexagonal Heavy-series nuts used with stud bolt. Heavy hex nut dimensions in inches are covered in ASME B18.2.2 Square and Hex Nuts; however, the dimensions in matrix unit are covered in ASME B18.2.4.6M Heavy Hex Nuts. I have listed the Heavy hex nut dimensions as per ISO and UNC.

ISO Heavy hex nut dimensions

| ISO Nut NB | Across Corners | MAX Thickness | MIN Thickness | MAX Across Flats | MIN Across Flats |

|---|---|---|---|---|---|

| M 8 | 14.38 | 6.8 | 6.44 | 13 | 12.73 |

| M 10 | 17.77 | 8.4 | 8.04 | 16 | 15.73 |

| M 12 | 20.03 | 10.8 | 10.37 | 18 | 17.73 |

| M 14 | 23.35 | 12.8 | 12.1 | 21 | 20.67 |

| M 16 | 26.75 | 14.8 | 14.1 | 24 | 23.67 |

| M 18 | 29.56 | 15.8 | 15.1 | 27 | 26.16 |

| M 20 | 32.95 | 18 | 16.9 | 30 | 29.16 |

| M 22 | 37.29 | 19.4 | 18.1 | 34 | 33 |

| M 24 | 39.55 | 21.5 | 20.2 | 36 | 35 |

| M 27 | 45.2 | 23.8 | 22.5 | 41 | 40 |

| M 30 | 50.85 | 26.6 | 24.3 | 46 | 45 |

| M 33 | 55.37 | 28.7 | 27.4 | 50 | 49 |

| M 36 | 60.79 | 31 | 29.4 | 55 | 53.8 |

| M 39 | 66.44 | 33.4 | 31.8 | 60 | 58.8 |

| M 42 | 71.3 | 34 | 32.4 | 65 | 63.1 |

| M 45 | 76.95 | 36 | 34.4 | 70 | 68.1 |

| M 48 | 82.6 | 38 | 39.4 | 75 | 73.1 |

| M 52 | 88.25 | 42 | 40.4 | 80 | 78.1 |

| M 56 | 93.56 | 45 | 43.4 | 85 | 82.8 |

| M 60 | 99.21 | 48 | 46.4 | 90 | 87.8 |

| M 64 | 104.86 | 51 | 49.1 | 95 | 92.8 |

| M 68 | 110.51 | 54 | 52.1 | 100 | 97.8 |

| M 72 x 6 | 116.16 | 58 | 56.1 | 105 | 102.8 |

| M 76 x 6 | 121.81 | 61 | 59.1 | 110 | 107.8 |

| M 80 x 6 | 127.46 | 64 | 62.1 | 115 | 112.8 |

Flange and Olet Quiz – Test yourself, Take This Quiz

Unlock New Skills with Our Best Selling Online Courses

UNC Heavy hex nut dimensions

| UNC Nut N/B | Max Across Corners | Min Across Corners | Max Thickness | Min Thickness | Max Across Flats | Max Across Flats |

|---|---|---|---|---|---|---|

| 3/8 | 20.2 | 19.4 | 9.6 | 8.7 | 17.5 | 17 |

| 7/16 | 22 | 21.1 | 11.2 | 10.2 | 19 | 18.5 |

| 1/2 | 25.6 | 24.6 | 12.8 | 11.8 | 22.2 | 21.6 |

| 9/16 | 27.5 | 26.3 | 14.4 | 13.4 | 23.8 | 23.1 |

| 5/8 | 31.2 | 29.8 | 16 | 14.9 | 27 | 26.2 |

| 3/4 | 36.7 | 35.1 | 19.3 | 18 | 31.8 | 30.8 |

| 7/8 | 42.2 | 40.4 | 22.5 | 21.2 | 36.5 | 35.4 |

| 1 | 47.7 | 45.6 | 25.7 | 24.3 | 41.3 | 40 |

| 1 1/8 | 53.2 | 50.8 | 28.9 | 27.4 | 46 | 44.6 |

| 1 1/4 | 58.6 | 56.1 | 31.8 | 30.1 | 50.8 | 49.2 |

| 1 3/8 | 64.2 | 61.4 | 35 | 33.3 | 55.6 | 53.8 |

| 1 1/2 | 69.6 | 66.6 | 38.2 | 36.4 | 60.3 | 58.4 |

| 1 5/8 | 75.2 | 71.8 | 41.5 | 39.5 | 65.1 | 63 |

| 1 3/4 | 80.6 | 77.1 | 44.7 | 42.6 | 69.9 | 67.6 |

| 1 7/8 | 86.2 | 82.3 | 47.9 | 45.8 | 74.6 | 72.2 |

| 2 | 91.6 | 87.6 | 51.1 | 48.9 | 79.4 | 76.8 |

| 2 1/4 | 102.6 | 98.1 | 57.2 | 54.7 | 88.9 | 86.1 |

| 2 1/2 | 113.6 | 108.6 | 63.6 | 61 | 98.4 | 95.2 |

| 2 3/4 | 124.6 | 119.1 | 70.1 | 67.2 | 108 | 104.4 |

| 3 | 135.6 | 129.6 | 76.5 | 73.5 | 117.5 | 113.7 |

Are You Piping Components Master?