Pipe Fittings – Elbow, Reducing Elbow, Miter bend, and Returns

Welcome to Hardhat Engineer. I am Varun Patel.

In this video, I am going to teach you about pipe fittings. In part one, I will teach you about the elbow, reducing elbow, miter bend, and returns that are 180-degree bends.

Please subscribe to my channel to get regular updates on new videos and also like and share this video with your friends. If you have any questions or want to know something different, please write in the comment below. If you are a first-time visitor, I have a free gift at the end of the video, so please do watch till finished.

What is pipe fitting? In oil and gas piping, pipe Fittings are a Piping component that helps change the flow direction, such as elbows and tee. Changes the size of the pipe such as reducers, reducing tees. Connect two components together, such as couplings, and stop the flows such as Caps.

Elbow:

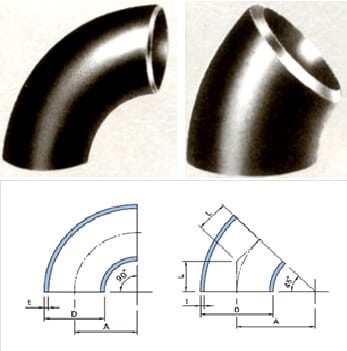

The elbow is used more than any other pipe fittings. It provides flexibility to change the pipe direction. Elbow is mainly available in two standard types, 90° and 45°. However, you can manufacture the elbow in any other degree or cut the standard elbow to any degree as required during the construction.

Elbows are available in two radius types, Short radius (1D) and Long Radius (1.5D).

A Long Radius elbow has a radius equivalent to 1.5 times the diameter of the pipe, and a Short Radius elbow is having a radius equivalent to the Diameter of the pipe.

- Long Radius A=1.5D

- Short Radius A=1D

Ok, now tell me which type of elbow you will use if you want to transport fluids to long distances with minimum pressure loss. And piping that has frequent directional changes? Well, in both cases, a long radius elbow is used as pressure loss is much less in a long radius than in a short radius elbow. A short radius elbow is used where space is really constrained, and pressure loss is not a problem. When you use a short radius elbow in piping, you may need to install a larger pump or compressor to compensate pressure loss.

Pipe FIttings Quiz – Test yourself, Take This Quiz

Unlock New Skills with Our Best Selling Online Courses

Reducing Elbow:

The 90 reducing elbows are designed to change direction and reduce the flow length within a piping system. The reducing elbow eliminates one fitting and reduces the welding by more than one-third. Can you tell me which fits its elements? Yes, reducer, and that is why it reduces 2 cirseam weld joint and reduce the welding by 1/3. Also, the gradual reduction in diameter throughout the arc of the reducing elbow provides lower resistance to flow and reduces the effect of stream turbulence and potential internal erosion. These features prevent sizeable pressure drops in the line.

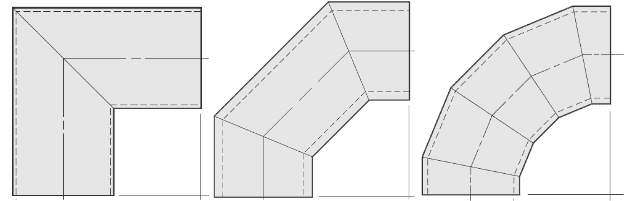

Miter bend:

Miter bends are not standard fittings they are fabricated from pipes. High skilled pipe fitter is required to fabricate this type of bend, and Usually, they are preferred for sizes 10” & above because large size elbow is expensive. The use of miter bend is restricted to the waterline. Miter bend can be fabricated in 2, 3, & 5 pieces. Generally, you can see the use of miter bend in the fire water line and cooling water in old refinery & petrochemical plant. Nowadays, the use of miter bend is limited.

Returns/ bends:

Returning elbows or pipe bends are used to make a 180º direction change. These bends are also available in short & long patterns similar to the short radius and long radius elbow. Bends are mainly used in heating coils and heat exchangers.

Please subscribe to my channel to get regular updates on new videos and also like and share my video with your friends. If you want to request a video, please write in the comment below. And don’t forget to check the free piping component guide by visiting my website. See you soon, goodbye, take care.

Subscribe to my Youtube channel: https://goo.gl/9OktFA

Are You Piping Components Master?