Welcome to the hardhatengineer short video. In this video, you will learn about the difference between weldolet and Threadolet.

Please do like and share this video, and don’t forget to subscribe.

Let’s start with the video.

Both weldolate and threadolet are self-reinforced branch fittings developed by a Company called Bonney Forge.

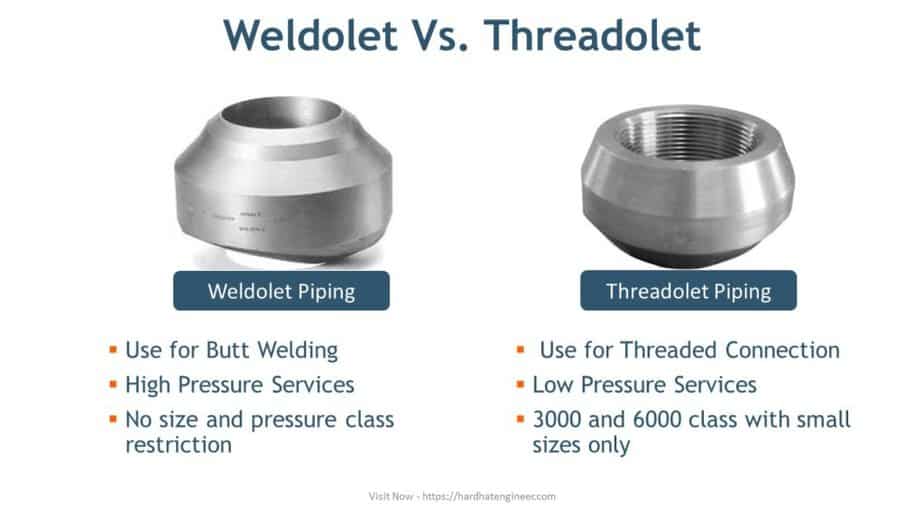

Here in the image, you can see both weldolate and threadolet.

Let’s see the difference between weldolate and threadolet.

| Weldolet | Threadolet |

| Use for Butt Welding | Use for Threaded Connection |

| High Pressure Services | Low Pressure Services |

| No size and pressure class restriction | 3000 and 6000 class with small sizes only |

Flange and Olet Quiz – Test yourself, Take This Quiz

Unlock New Skills with Our Best Selling Online Courses

The first difference is the use of these two. When threaded branch connections are required from the pipe header, threadolet is used, and when you need a butt weld connection to the pipe branch, weldolate is used.

The second difference is a use case. Threadolet is used for small size piping with a low-pressure application. There is no such restriction in the case of weldolate, which can also be used for high-pressure applications.

The third difference is available seizes. Weldolate can be manufactured using any size to suit the requirement. Threadolet is mostly available in 3000 and 6000 pressure classes with limited size as uses are limited to small tapings.

This is the end of the video. See you soon with the next short video. Goodbye and take care.

Are You Piping Components Master?