A Butterfly valve is a quarter-turn rotary motion valve that is used to stop, regulate, and start the flow. Butterfly valves are a quick open type. A 90° rotation of the handle can completely close or open the valve. Normally, they are used in systems where a positive shut-off is not required. In this article, you will learn about the following types of Valve.

- Wafer Type

- Lug Style Type

- Flanged Type

- Butt Welded Ends Types

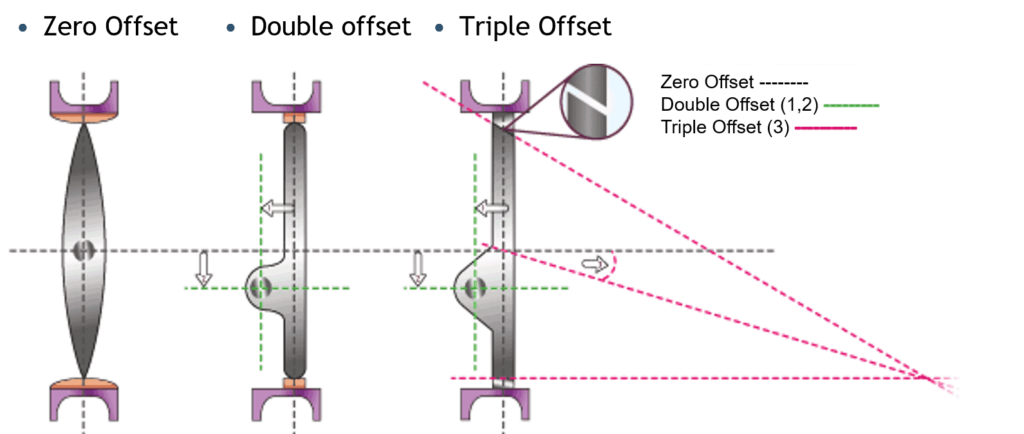

- Zero offset

- Double Offset

- Triple Offset

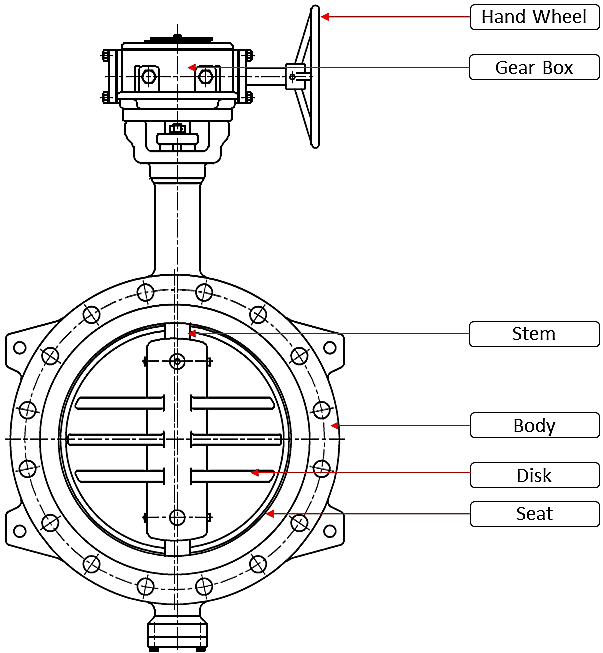

Large Butterfly valves are usually equipped with a gearbox-type actuator, where the handwheel is connected to the stem via a gearbox. This will reduce the force and, at the same time, the operation’s speed. This type of valve should be installed in the open position.

If the valve is closed during installation, the rubber seat will wedge against the valve disc, making it difficult to open.

Unlock New Skills with Our Best Selling Online Courses

Types of Butterfly Valves Based on Body Construction

Butterfly valves are available in the following types based on the type of ends of the body.

- Both Flanged Ends

- Wafer Type Ends

- Lug Type Ends

- Butt Welded Types Ends

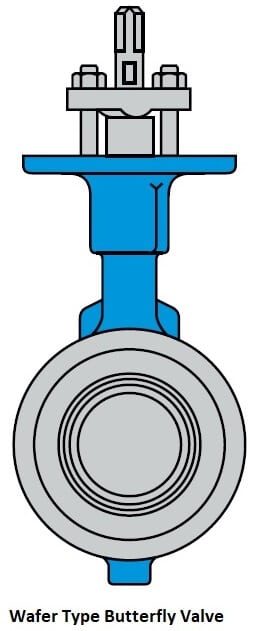

Wafer Types

The wafer body is placed between pipe flanges, and the flange bolts surround the valve body. A wafer-type butterfly valve is easy to install, but it cannot be used as an isolation valve.

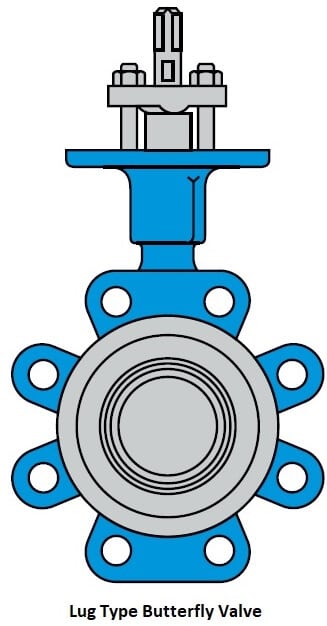

Lug Style

The lug body has protruding lugs in the periphery of a body that provides passage to bolt holes that match with those in the flanges.

Valve Quiz – Test yourself, Take This Quiz

Unlock New Skills with Our Best Selling Online Courses

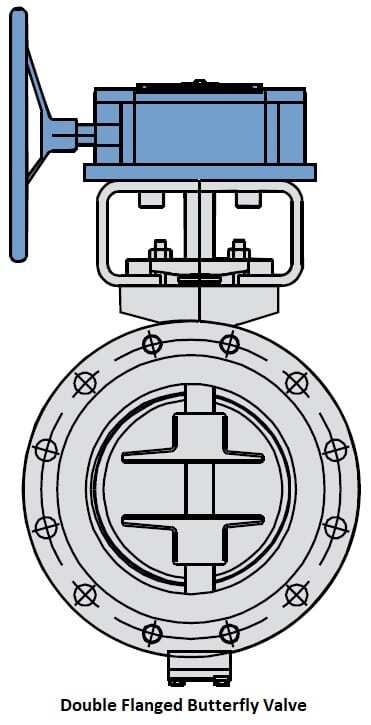

Flanged Type

In this type, the body has a flange that matches with pipe flange dimension.

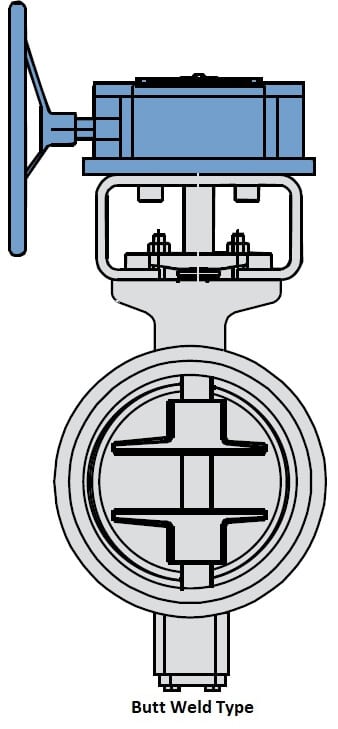

Butt Welded Ends Types

These types of ends are used in high-pressure services and it directly welded to the pipe.

Zero offset Butterfly Valve

A zero offset design is used for the valve that is used in low-pressure and temperature services. In this design, the disc and shaft axis is concentric with the valve body. In the open position, the disc divides the flow into two equal halves, with the disc in the middle and parallel to the flow.

This type of valve has a resilient seat. Sealing is achieved when the disc deforms the soft seat. There is friction between the disk and seat during the full operating cycle, which is the disadvantage of a zero offset valve.

Double Offset Butterfly Valve

In Double Offset, the disk is offset from the valve center line and also from the valve body center line. You can see this in the image where one and two are written. This creates a cam action during operation that lifts the seat out of the seal.

Double offset makes opening and closing smooth as friction is applicable only during the first few degrees of opening and final few degrees of closing, approx 10 degrees of opening and closing.

Unlock New Skills with Our Best Selling Online Courses

Triple Offset Butterfly Valve

In the Triple Offset design, the third offset is created by the geometrical design of the seating surface. The seat is machined into an offset conical profile resulting in a right-angled cone. You can see this in the third image with a small enlargement of the seating angle.

This ensures frictionless stroking throughout its operating cycle. Contact is only made at the final point of closure with the 90° angle acting as a mechanical stop; the Metal seated valve uses a triple offset design.

Butterfly Valve Body Parts

The typical butterfly valve has a short circular body, a round disk, shaft, and metal or soft seats. You can see the parts in the above image. Check the video below for the functioning of the valve.

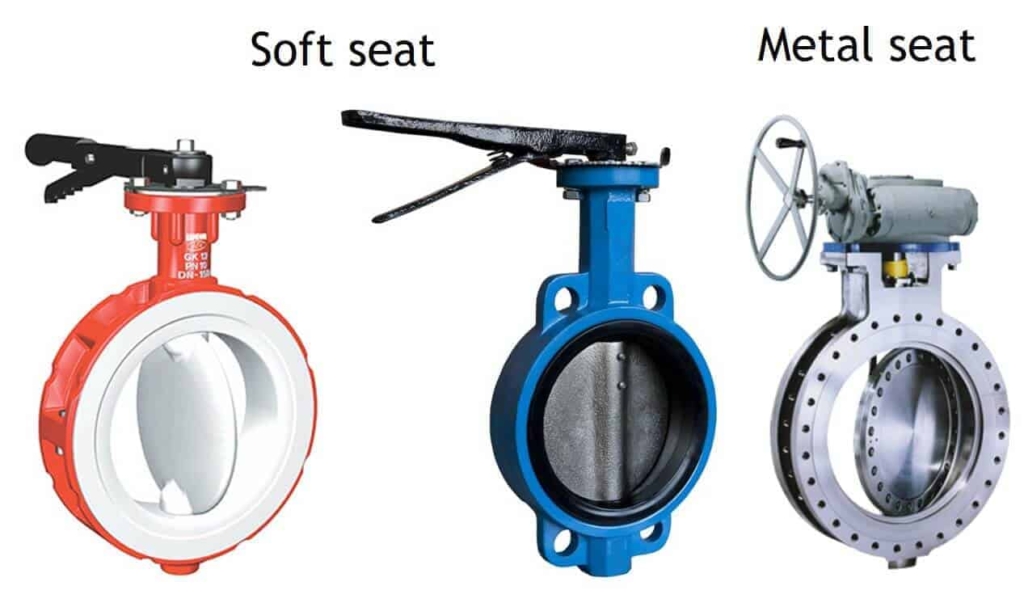

Seat Types

Butterfly valves can be metal-to-metal seated, soft seated, or with a fully lined body and disc. The first image is of a soft, seated, fully lined body and disc valve. The second is a soft seat with a metal disk, and the third is metal to metal seat type valve.

The disk of the butterfly valve can be concentric or eccentric with the valve body. Here I have shown three different arrangements of the disk with respect to the center of the valve body.

Applications

- A Butterfly valve is used in many different fluid services and performs well in slurry applications. They can be used in liquids, steam, cryogenics, cooling water, air, gasses, firefighting & Vacuum services.

- Butterfly Valve is used in all types of industries, even in High-pressure and temperature services.

Advantages

- Butterfly Valve is suitable for large valve applications due to its compact, lightweight design that requires considerably less space as compared to other valves.

- Due to a quick operation, it needs less time to open or close

- The maintenance costs are usually low compared to other valve types

- A pressure drop across a butterfly valve is small

- Valve with Non-metallic seating can be used in chemical or corrosive media.

Disadvantages

- Throttling is limited to low differential pressure services and that too with a 30- to 80-degree disc opening.

- There is a chance for cavitation and choking as the disk is always in the flow Turbulence flow can affect the disc movement.

Click here to learn about Other Types of Valve

Unlock New Skills with Our Best Selling Online Courses