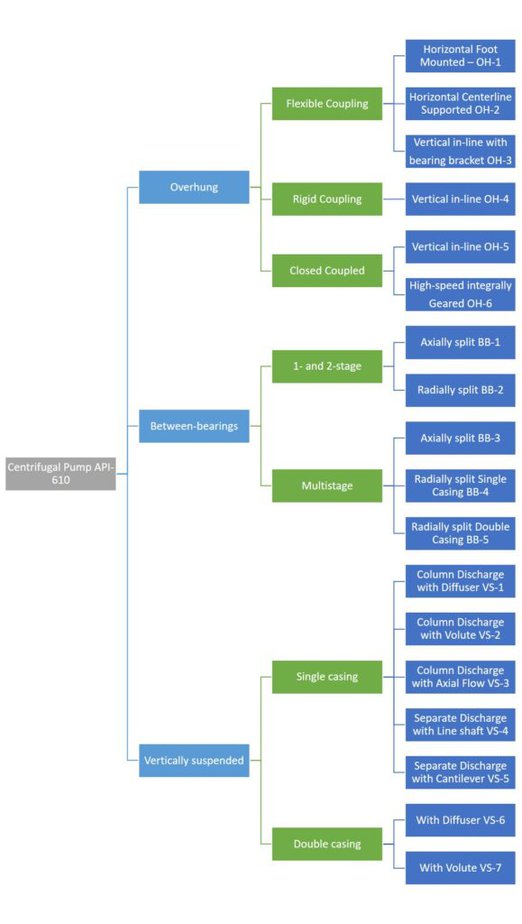

API 610 is the standard for the centrifugal pump used in petroleum industries. It has categorized the pump based on the construction. The chart given below lists the classification of pumps based on API 610. Overhung, Between Bearing, and Vertically Suspended are three main categories of API 610 Centrifugal Pump types.

OH1 Type Pump

The image shown here is OH1 (Overhung) type API 610 Centrifugal pump types. This is a single-stage overhung with a foot-mounted base plate design. It is a horizontal pump with a flexible coupling. You can see in the image that the leg supports it at the opposite end of the suction.

All API Pump Image Sources – Ruhrpumpen

OH2 Type Pump

This type of pump is centerline supported. You can see that there is no leg support at the bearing end as compared to the OH1 type in the image below. It is also single stage end suction pump with single bearing housing. During operation, this bearing housing helps to absorb the force imposed on the pump shaft. It also ensures the proper position of the impeller during the operation.

OH3 Type Pump

OH3 pump is flexibly coupled single-stage and in-line pump with overhung impeller. It has a separate bearing bracket. It comes with integral bearing housing, which helps in absorbing pump load. The motor is directly mounted on the pump. The image below shows the OH3 type of pump.

OH4 Type Pump

The only difference between OH3 and OH4 is the use of a rigid coupling method in OH4 compared to flexible coupling in OH3.

Centrifugal Pump Quiz – Test yourself, Take This Quiz

Unlock New Skills with Our Best Selling Online Courses

OH5 Type Pump

OH5 type pump is a closed coupled pump. The impeller of the pump is directly attached to a driver on the same shaft. It is a vertical, in-line, and single-stage pump.

OH6 Type Pump

OH6 is a high-speed pump as it uses speed increasing gearbox. The impeller is mounted directly on the gear shaft. The gearbox is connected with a driver by a flexible coupling. It is a single-stage overhung pump that can be installed both vertically and horizontally.

Image Source – Sundyne

BB1 Type Pump

The second category of API 610 centrifugal pump is between bearing pump.

BB1 (Between Bearing) is a horizontally installed one or two-stage pump. The casing of this pump is an axially split type.

BB2 Type Pump

The difference between BB1 and BB2 is the way the casing is split. In BB2, the casing is radially split type.

BB3 Type Pump

A multistage between bearing pumps with Axially Split cashing design is designated as an API BB3 Type pump. This pump used flexible coupling to connect the drive.

BB4 Type Pump

In this API pump design, each stage of the pump is like a ring and connected through tie rode around them. If you see the image, it will be clear why this pump is also called a ring section pump. Each stage is a radially split design and installed on the shaft supported by bearings at both ends.

Unlock New Skills with Our Best Selling Online Courses

BB5 Type Pump

BB5 type pump is known as Barrel Pump due to its barrel-like design. It is used in high-pressure services. It is a multistage, double casing, a radially split design that uses flexible coupling.

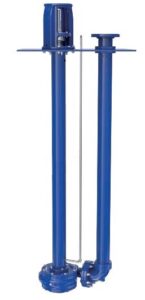

VS1 Type Pump

VS1 type pump is a single casing vertically suspended type design. It is used as a wet pit or diffuser pump. The column of a pump is used as a discharge from the pump.

VS2 Type Pump

VS2 type pump uses volute casing design as compared to VS1. Other factors are similar to the VS1 type pump.

VS3 Type Pump

VS3 type pump is axial flow, and single casing vertically suspended type design. Pump column over which pump assembly is mounted, used as discharge from the pump.

VS4 Type Pump

This type of pump has a separate discharge column. It has a volute casing design. The vertically suspended shaft can be supported through intermediate bearings.

VS5 Type Pump

VS5 also has a separate discharge column. The difference is in the vertically suspended shaft. In the case of VS5, there will be no intermediate bearings. The pump shaft is a cantilever and supported by a top bearing.

VS6 Type Pump

VS6 pump has a double casing. It is also known as a can pump due to this design. It is a vertically suspended pump with discharge through the pump column. This design is used to increase NPSH in some cases by installing a pump underground.

VS7 Type Pump

The last API 610 centrifugal pump type is VS7. VS7 type pump uses volute casing design as compared to VS6. Other factors are similar to VS6.

Learn more about different types of centrifugal pump.

Reference for Images

- Flowserve – https://www.flowserve.com/en/products/pumps

- Ruhrpumpen – https://www.ruhrpumpen.com/en/products

- Sundyne – https://www.delta-p.no/products/api-610-pumps/

Are You Piping Components Master?