In this blog, you will learn about What is the difference between 3.1 and 3.2 Material test certificates? Before that let me explain about what is material test certificate.

The main difference between 3.1 and 3.2 Material test certificates is level inspection performed on the material before issuing the cetificate. Let’s learn the same in detail.

What is a Material Test Certificate (MTC)?

A material test certificate MTC, also known as a mill certificate, is an official document provided by the manufacturer or supplier to the purchaser that validates the properties and characteristics of the material being used.

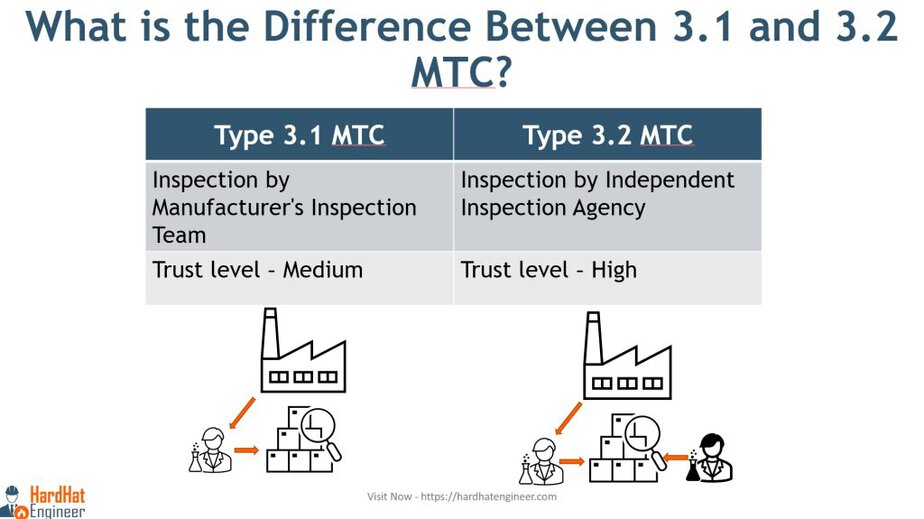

Here, in the table, you can see when Type 3.1 MTC is being issued and when Tyep3.2.

| Type 3.1 MTC | Type 3.2 MTC |

| Inspection by Manufacturer’s Inspection Team | Inspection by Independent Inspection Agency |

| Trust level – Medium | Trust level – High |

Type 3.1 Material Test Certificate

The 3.1 material test certificate is issued by the manufacturer and states that the material has been tested in accordance with specific standards. It confirms the chemical composition, mechanical properties, and other essential parameters.

However, the inspection and testing process are carried out by the manufacturer’s Inspection department, which is not part of the manufacturing department. So, here trust level is not that high as everything is in-house business.

Type 3.2 Material Test Certificate

For critical applications, we have to be 100% sure about our material. This issue is solved by the Type 3.2 certificate.

The 3.2 material test certificate takes the level of assurance to a higher degree. This certificate involves the intervention of an independent third-party inspection agency. This third party may be the purchaser’s authorized person or independent inspection agencies. They conduct additional checks, verifications, and tests to ensure that the material meets the specified requirements.

The third-party inspector reviews the manufacturing process, performs random sampling, and may even witness specific tests. This comprehensive evaluation guarantees a higher level of confidence in the quality and integrity of the material being certified.

I hope you found this video helpful in understanding the difference between the 3.1 and 3.2 material test certificates. If you enjoyed this video, make sure to hit the like button and subscribe to my channel for more informative videos like this one.