With the increase in technological advances, lined and clad materials are getting popular in Process industries. By combining two materials, we can get the advantage of the two materials at a low cost. In this lecture, I will teach you about lined & clad materials used in piping.

Lined Pipe

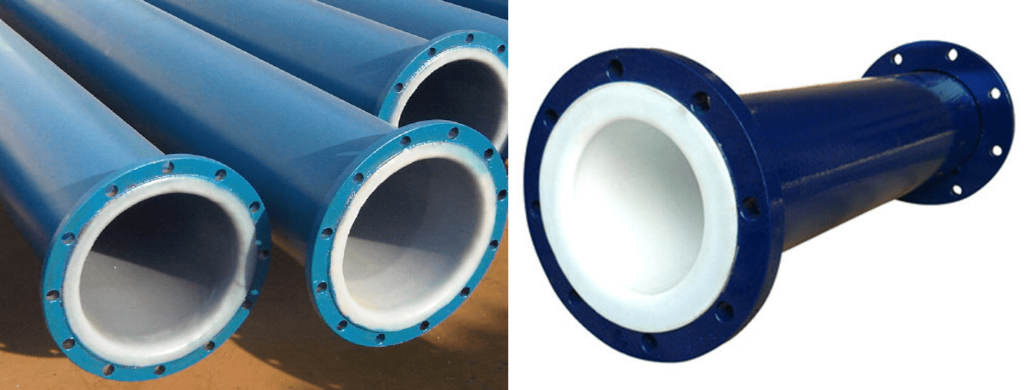

The lined pipe has a Mechanical bonding between pipe and line material.

- By applying a lined material to a carbon steel pipe, we can get the benefit of anti-corrosion property of lined material and the strength of carbon steel.

- Commonly used lined materials are

- PTFE

- Rubber

- Glass

- FRP (Fiber reinforced plastic)

You can see the images of the lined pipe.

Image – PTFE India

Advantages of Lined Pipe

- A lined pipe can withstand tough chemical environments

- And Also offer an abrasion-resistant property with hard-lined material

- It is a cost-effective solution for non-critical services

Disadvantages of Lined Pipe

- Lined Pipe has a limitation of non-metal such as it cannot be used in high temperature and pressure services.

- The lined pipe is manufactured in small length pipe spools hence, large no of flange joints in line, which increases maintenance costs and chances of leakages.

Clad Pipe

A clad pipe has a Metallurgical bond between pipe and cladding material

- The cladding is done by an explosive bonding process or by welding clad material on a pipe

- High-strength carbon steel materials are cladded with high corrosion-resistant metal to achieve cost benefits

- Here you can see the clad pipe

Image – Butting.com

Piping Component Quiz – Test yourself, Take This Quiz

Unlock New Skills with Our Best Selling Online Courses

Advantages of Clad Pipe

Clad carbon steel can withstand tough chemical environments.

- A clad pipe can be used in high temperature and pressure services

- It is cost-effective for critical services as carbon steel can be used with a cladding of exotic materials.

Disadvantages of Clad pipe

- Fabrication of clad material is difficult, a special skill required for welding.

- Clad pipes are costly compared to lined pipe

Summary – Difference Between Lined and Clad Pipes

| Lined Pipe Vs Clad Pipe | |

|---|---|

| Lined Pipe | Clad Pipe |

| Use Non-metallic Material for lining | Use Metallic Material for cladding |

| Mechanical bonding with adhesive | Metallurgical bonding with welding or explosion bonding |

| Preferred in low pressure and temperature application | Use in all high pressure and temperature application as well |

| Fabrication is easy as mostly bolted joints | Fabrication is complicated due to dissimilar welding. |

| Less costly | Costly |

Are You Piping Components Master?