Inward material Inspection is an essential part of the fabrication process for piping and equipment used in Oil and Gas facilities. It serves as a quality control measure to ensure that the materials used in the process plant meet the required specifications and standards.

In this article, you will learn what inward material inspection is. what you should check during the inspection, and how to prepare the Inward Material Inspection Report (IMIR).

Table of Contents

What is Inward Material Inspection?

Inward Material Inspection is the process of inspecting all raw materials, such as pipes, plates, flanges, fittings, and any other materials at the site store or warehouse before being issued for fabrication. It is a routine practice and integral to the project quality management system.

The inspection department confirms that the correct material has been received in the ordered quantity and with the proper documentation. In other words, it is like checking the delivery of your online order before using the product.

Please note that inward material inspection is not a product quality inspection but a product verification inspection. It is a two-part process, where you check the documentation in the first part and physically verify the materials in the second part.

How to Do Inward Material Inspection?

Inward Material Inspection consists of two parts:

Documentation Verification

Before conducting the physical inspection of materials, it is crucial to ensure that all the required documents are in place. These documents provide vital information about the materials and their compliance with relevant standards. Some of the key documents to check include:

- Inspection Release Note (IRN): This note confirms that the materials have undergone inspection and are approved for use.

- Packing List: It provides a detailed list of the materials contained in the shipment.

- Inspection and Test Reports: These reports, such as Material Test Certificates (MTC) and dimension reports, provide information about the material’s properties and test results.

- Compliance Certificate: This certificate indicates that the materials meet the required compliance standards.

- Manufacturing Record Book (MRB): It contains a comprehensive record of the materials’ manufacturing processes.

- Installation Manual: This manual guides the proper installation of specific equipment or components.

It’s worth mentioning that not all documents may be applicable to every situation. Some documents, such as MRB and the Installation Manual, are only required for equipment and tag items, not for bulk materials such as piping, electrical, and instrument.

Unlock New Skills with Our Best Selling Online Courses

Physical Material Verification

The physical verification of materials is conducted in the field to establish their identification before they are issued for fabrication. During this stage, several aspects need to be assessed:

- Overall Material Quality: Check for any signs of rusting, paint damage, or other quality issues.

- Packaging Condition: Ensure that the packaging is intact and suitable for protecting the materials during transportation.

- Quantity Received: Verify that the received quantity matches the ordered quantity.

- Transit Damage: Inspect for any dents, breakages, or other damages that may have occurred during transit.

It is essential to record all observations and findings during the physical verification process. Positive Material Identification (PMI) is carried out for alloy and stainless steel materials to ensure their composition meets the required specifications. As indicated in the Material Test Certificate (MTC), the material’s marking plays a critical role in the inspection process.

Once all the requirements are met, an Inward Material Inspection Report (IMIR) is prepared, and the materials are marked with a unique identification (ID) to ensure traceability throughout the fabrication process. This unique ID differs from the original marking that comes with the product. It serves as a shorter, easily maintainable marking during fabrication and installation.

How to Prepare Inward Material Inspection Report (IMIR)?

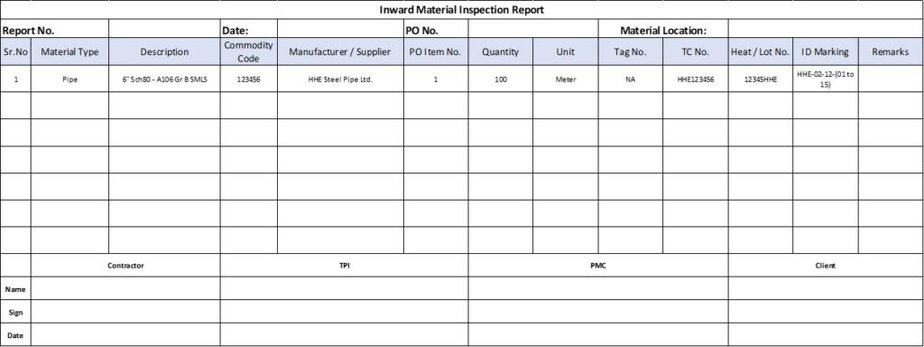

The Inward Material Inspection Report is a comprehensive record of the inspection findings and the first step for the material traceability system. It includes the following information:

- Report Number: A unique identifier for the inspection report.

- Purchase Order Number: The number associated with the purchase order for the materials.

- Inspection Date: The date when the inspection was conducted.

- Material Location: The designated location of the materials.

- Material Type: The type of material being inspected (e.g., pipe, elbow, tee, valve).

- Description: Technical details about the product, including applicable material standards, specifications, size, thickness, schedule number, and material grade.

- Supplier Name: The name of the manufacturer or supplier from whom the materials were procured.

- Commodity Codes: Short codes used to identify specific material types in the drawings, aiding proper material identification.

- PO Item Number: The serial number of the material in the purchase order.

- Quantity Unit: The unit of quantity used for the specific type of material (e.g., meters, numbers, kilograms).

- Tags: For assembled items such as valves, filters, or instrument items, tags are listed in the IMIR report.

- MTC and Heat Numbers: The Material Test Certificate (MTC) and Heat Numbers are recorded to confirm appropriate testing and quality standards. Heat Numbers provide unique identification for a specific batch or lot of material during its manufacturing process.

- Unique ID: A marking assigned to each item to ensure traceability throughout the fabrication and installation processes. It is a shorter version that can be easily maintained during the fabrication. Each company has a different method of giving ID to the material.

- Remarks: Here, you can add any observation about the material.

The IMIR report helps maintain a clear record of the inspection process and serves as a reference for future use.

Usually, this marking transfer is done during the cutout marking inspection.

Piping Component Quiz – Test yourself, Take This Quiz

Conclusion

Inward Material Inspection is a crucial step in the fabrication process of piping and equipment used in Oil and Gas facilities. By verifying the received materials against documentation and conducting physical inspections, it ensures the adherence to required specifications and standards. Preparing an Inward Material Inspection Report (IMIR) provides a detailed record of the inspection findings and ensures traceability throughout the fabrication process.

Maintaining quality and traceability throughout the fabrication process is vital to ensure the integrity and safety of oil and gas facilities. By conducting thorough inward material inspections, companies can mitigate risks and ensure the successful completion of their projects.

You can check our comprehensive online courses to enhance your knowledge and skills in the oil and gas industry. These courses offer practical insights and expertise from industry professionals, enabling individuals to advance their careers in this field.