Non-metallic materials are used in non-critical services such as water and drainage, where operating pressure and temperature are less than process lines. In this lecture, I will give you an overview of these materials.

Commonly used non-metallic piping materials are

- PVC / CPVC

- HDPE

- GRE/GRP

- And Cement pipes

These non-metallic materials offer some great advantages over metallic piping but also have some limitations. They are resistant to chemical attacks but poor in strength.

PVC / CPVC Pipes

- PVC – is Polyvinyl Chloride and

- CPVC – Chlorinated Polyvinyl Chloride (that has higher strength at elevated temperatures than PVC)

- PVC and CPVC are tough and exceptionally resistant to chemical attack

- PVC and CPVC require protection from ultraviolet exposure if installed outdoor and start softening when subjected to high temperatures.

- PVC/CPVC Pipes are made by an Extrusion process

- And Fittings, flanges, and valves are manufactured by the injection molding method.

- PVC has many applications in industries, and it’s also used in home water piping.

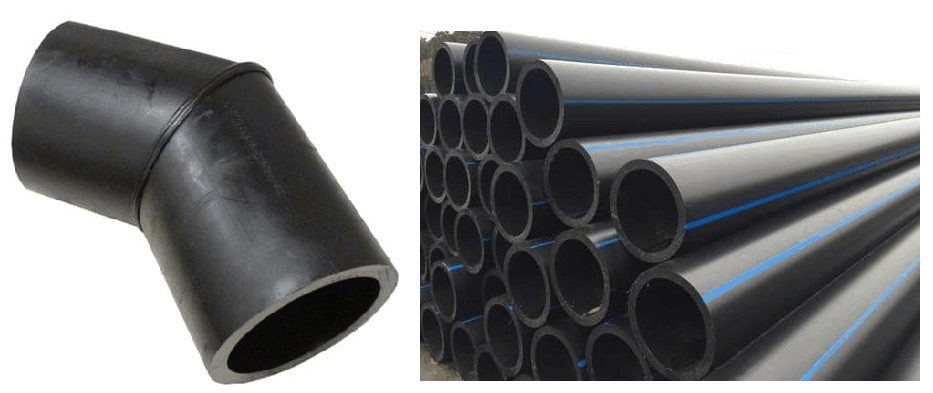

PE/HDPE Pipes

- High-Density Polyethylene has many desirable qualities over LDPE and PVC,

- It has improved tensile strength

- Improved low-temperature brittleness

- Higher softening point

- Higher chemical resistance

- HDPE pipes are manufactured by the extrusion process

- It is widely used in water distribution and low-pressure natural gas services

- It also used as lined material with carbon steel pipe

Piping Component Quiz – Test yourself, Take This Quiz

Unlock New Skills with Our Best Selling Online Courses

GRE/GRP Pipes

GRE/GRP pipes are gaining popularity in seawater and sewage transport applications. These pipes offer excellent corrosion resistance properties over all other types of pipes. The main difference between the GRE and GRP is the resin used for bonding the glass fiber.

GRP pipe uses Isophthalic Resin, whereas GRE pipe uses Epoxy Resin.

- GRP is Glassfibre reinforced plastic, is used in

- Water supply application, Wastewater / Sewerage collection, and seawater transport application

- GRE that is Glassfibre reinforced epoxy

- Pipes are used for industrial applications as they can withstand higher temperatures than GRP pipes.

- GRE pipes are used in the offshore platform and water treatment plant to handle salty water.

- Due to excellent chemical and corrosion resistance, it is also used as a lining material in sewage effluent tanks.

- GRP/GRE pipes are manufactured using the filament winding process.

Cement Pipes

Cement Pipes are not used for any process application. However, it is used in a processing facility for various other purposes.

- Cement pipes are manufactured from reinforced or non-reinforced concrete

- They mainly used in stormwater and gravity services

- They also used in culverts and irrigation application

Are You Piping Components Master?