Welcome to Hardhatengineer.com. I am Varun Patel. In this video, you will learn about the most common questions regarding piping that you may face during the interview.

You will learn about these questions;

- What is the difference between a machine bolt and a stud bolt?

- What is the thumb rule to calculate spanner size for a given bolt?

- What is steam tracing?

- Which piping items will you drop down before conducting Flushing and Hydrotest?

- Why do we provide a Dampener in the Piping of the Reciprocating Pump?

- Why do we provide a Full Bore Valve in connecting the pipeline of the Launcher / Receiver?

- What should be the relative hardness between the RTJ gasket and flange groove?

- Why do we provide Drip Leg in Steam Line?

- What is the normal upstream and downstream straight length of the orifice flowmeter?

- What do you mean by Composite Flange?

So please watch this video till the end. And don’t forget to subscribe to my channel; that way, you will get regular updates on a new videos. You can subscribe right now by just clicking the subscribe button on your screen. So let’s start with the first question.

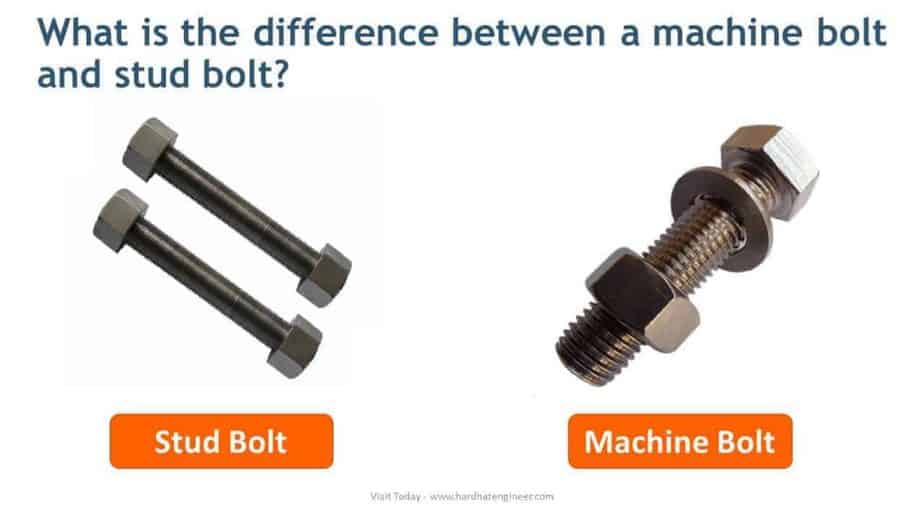

What is the difference between a machine bolt and a stud bolt?

This is sometimes confusing, especially for newcomers. Bolt and stud are very frequently used in the flange joint. So some people use these terms interchangeably, but that is not correct. A machine bolt has a head on one side and a nut on the other, but a stud bolt has a thread on the full body and nuts on both sides.

In the image, you can see the machine bolt and stud. Normally in piping, machine bolts are used with non-metallic piping such as GRE/GRP and HDPE. For metallic piping, stud bolts are used.

What is the thumb rule to calculate spanner size for a given bolt?

A standard chart is available that shows the size of a given bolt and the corresponding spanner size. Here you can see the same. But if this chart is not available, in that case, you can use the thumb rule to get the spanner size. Approx spanner size is 1.5 times the diameter of Bolt.

| Wrench Sizes (in.) | ||

|---|---|---|

| Diameter of the Bolt | Hex Nut | Heavy Hex Nut |

| 1/4 | 7/16 | |

| 5/16 | 1/2 | |

| 3/8 | 9/16 | |

| 7/16 | 5/8 | |

| 1/2 | 3/4 | 7/8 |

| 9/16 | 13/16 | |

| 5/8 | 15/16 | 1 1/16 |

| 3/4 | 1 1/8 | 1 1/4 |

| 7/8 | 1 5/16 | 1 7/16 |

| 1 | 1 1/2 | 1 5/8 |

| 1 1/8 | 1 11/16 | 1 13/16 |

| 1 1/4 | 1 7/8 | 2 |

| 1 3/8 | 2 1/16 | 2 3/16 |

| 1 1/2 | 2 1/4 | 2 3/8 |

| 1 3/4 | 2 5/8 | 2 3/4 |

| 2 | 3 | 3 1/8 |

| 2 1/4 | 3 3/8 | 3 1/2 |

| 2 1/2 | 3 3/4 | 3 7/8 |

| 2 3/4 | 4 1/8 | 4 1/4 |

| 3 | 4 1/2 | 4 5/8 |

Piping Component Quiz – Test yourself, Take This Quiz

Unlock New Skills with Our Best Selling Online Courses

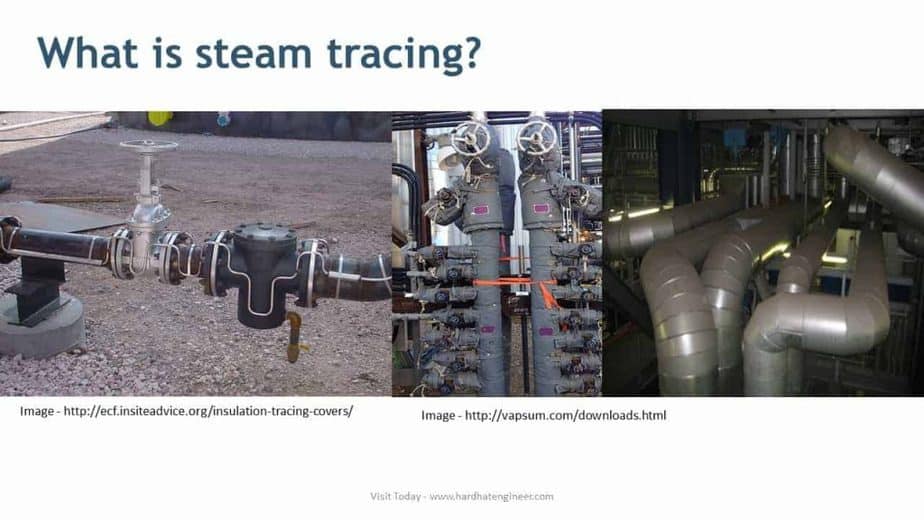

What is steam tracing?

As the name suggests, it is a tracing of steam provided to the process line. In a process plant, certain fluid such as fuel oil and intermediate feed pipeline that carries viscous fluids needs constant heating to maintain the flow in the line; otherwise, this fluid gets thicker and can jam the line.

To prevent this, constant heating of the line is required. In the image below, you can see that small tubes are attached to the main process pipeline. These tubes are known as a tracing line, and the steam that is passed through it continues to keep the main process line hot.

Once tracing is done, the pipeline is insulated to preserve the heat loss, as seen in the last image.

Which piping items will you drop down before conducting Flushing and Hydrotest?

When you perform a hydro test or do line flushing, debris such as pipe rust, welding slag, and sand will move, and it may get stuck inside the instrument and valve. This will create a problem in their function.

So any item that may get impacted by this type of debris must need to be dropped while performing flushing and hydro test. Items like Control valves, Orifice plates, Rotameters, safety valves, and Thermowells are dropped or replaced with temporary spools before a hydro test.

Why do we provide a Dampener in the Piping of the Reciprocating Pump?

To answer this question, you should know the functioning of the reciprocating pump. Unlike a centrifugal pump, fluid gets compressed in a fixed volume in a reciprocating pump. Here you can see how it works.

Now, this plus-like effect will create in the pipeline. This will damage the line. To prevent this dampener is installed with a pump that acts as a buffer and absorbs the high-pressure pulse, and releases the pressure when it is low. This way, constant pressure is maintained in the line.

Why do we provide a Full Bore Valve in connecting the pipeline of the Launcher / Receiver?

There are two types of valves available. Here is the image; you can see them both. The first is reduce bore, and the second is full bore. The main difference you can see in the image. It is basically an internal diameter of the valve. In the case of a full bore valve, the diameter of the valve passage is the same as a pipe.

Now launcher and receiver are used to launch the pig. Pigging is an activity that is used to clean the line and also to inspect the line with the help of an intelligent pig. Here you can see the pig. You must use a full bore valve to pass this pig through a pipeline without getting stuck at the valve.

What should be the relative hardness between the RTJ gasket and flange groove?

In the image, you can see the RTJ flange and gasket. Now the material of the gasket should be soft enough to set inside the flange serration to prevent leakage, and at the same time, it should not damage the flange face when you tighten the flange.

The slightly soft gasket material is used to achieve this, then flange material. The hardness of the gasket will be 20-50 BHN less than the hardness of the flange. This will make ensure the smooth setting of a gasket in the flange face.

Why do we provide Drip Leg in Steam Line?

There is a chance of steam condensation inside the steam line. If you don’t remove this condensate from the line, it will create a water hammer inside the line and damage the piping system.

To avoid this, you must continuously remove the condensate from the system. A drip leg is provided to remove condensate when there is a rise in the pipe along the flow direction. Here is the image; you can see the drip leg.

What is the normal upstream and downstream straight length of the orifice flowmeter?

An orifice flowmeter is used to measure the flow of the pipeline. To get an accurate result, a steady flow is necessary. Any piping component will create some amount of turbulence in the line.

To avoid this, a straight pipe is preferred in upstream and downstream of the orifice meter. The minimum straight length preferring in upstream is 15 times the diameter of the pipe, and in downstream, it is five times the diameter of the pipe.

What do you mean by Composite Flange?

The flange that is made up of more than one material is called a Composite flange. See the image of the lap flange. Lap Flange has two components: a stub end and a loose backing flange.

The stub end is butt-welded to the pipe, and the Backing flange freely moves over the pipe. To save cost, a backing flange can be of a different material than stub material and generally of carbon steel.

This is the end of the video. I hope that you have learned from this video. In the next video, I will explain to you a few more important questions related to piping. So keep on checking my youtube channel for a new videos.

Visit my website hardhatengineer.com for free study materials, and don’t forget to subscribe to my channel to get regular updates on new videos. Please like and share my video with your friends. If you want to request a video, please write in the comment. See you soon. Goodbye, take care.

Are You Piping Components Master?