Welcome to Hardhatengineer.com. I am Varun Patel. In this video, you will learn about the most common questions regarding piping that you may face during the interview.

- What is the insulation gasket kit and where do you use it?

- What is the insulation joint?

- What is the minimum distance to be maintained between two welds in a pipe?

- What are the different types of insulation used in piping?

- What is the difference between GRE and GRP Pipe?

- What is the difference between the post-heating of weld and PWHT?

So please watch this video till the end. And don’t forget to subscribe to my channel because that way you will get regular updates on a new video. You can subscribe right now by just clicking the subscribe button on your screen. So let’s start with the first question.

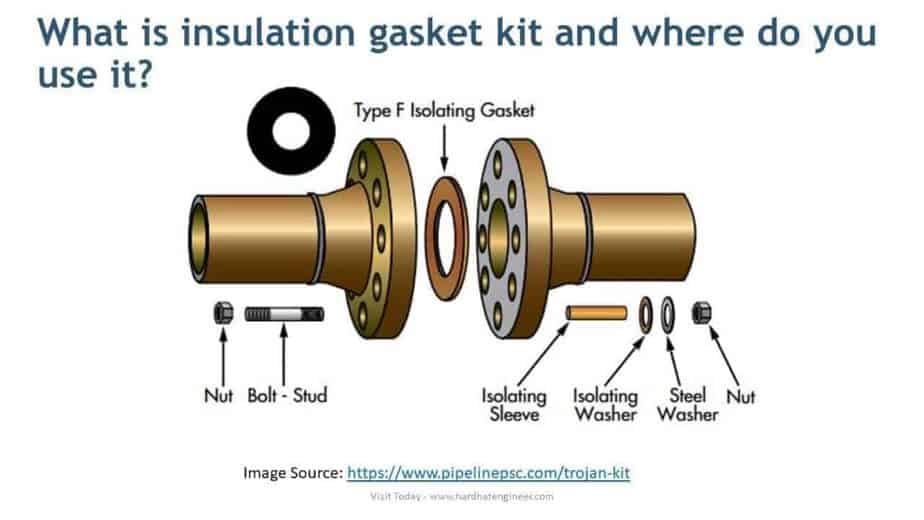

What is the insulation gasket kit and where do you use it?

The insulation gasket kit is a specially designed gasket package that use to prevent galvanic corrosion of flange face in a piping system when the material of connecting flanges is different.

Here, in the image, you can see the complete kit of insulation gasket. Basically, it prevents direct metal-to-metal contact between two different flange materials.

What is the insulation joint?

The insulation joint is used to break the current flow of an underground pipeline that is equipped with cathodic protection. To protect the underground pipeline from corrosion, cathodic protection is used. An external current is supplied to the pipeline.

However, if this current flow continues when the line goes above-ground, it will damage the paint that was applied to protect the above-ground pipeline. To avoid this situation, an insulation joint is used.

It is designed in such a way that it will break the flow of current. Here in the image, you can see the configuration of the insulation joint.

Piping Component Quiz – Test yourself, Take This Quiz

Unlock New Skills with Our Best Selling Online Courses

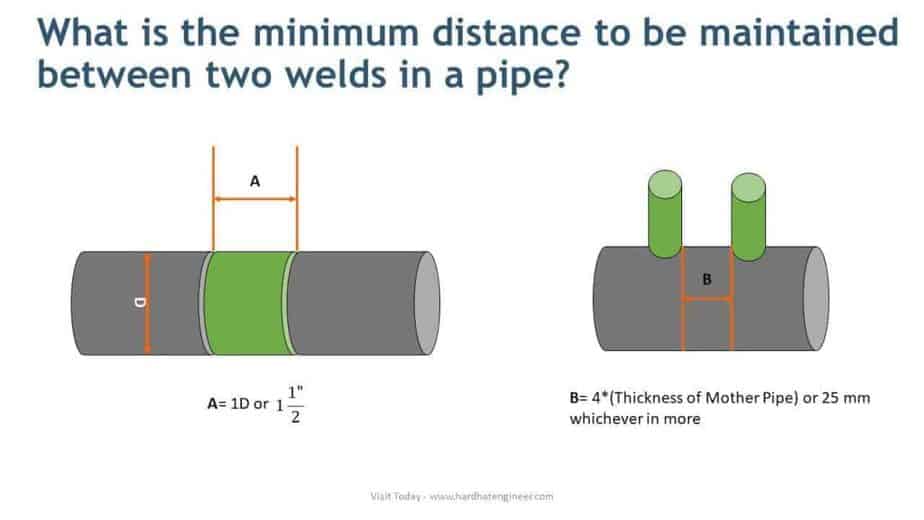

What is the minimum distance to be maintained between two welds in a pipe?

No, American code and standard mandate the minimum distance between two welds in a pipeline. But most company specifications will give you a minimum distance to maintain between two nearby welds. This is to avoid the overlapping of heat-affected zones.

The thumb rule is that the minimum distance between adjacent butt welds is 1D. If not, it is never closer than 1-1/2″. This is supposed to prevent the overlap of heat-affected zones. You can see what I am trying to explain in the image.

Here, A and B are two weld joints. The minimum distance between these two joints should be the one-time diameter of the pipe. So, if your pipe is 4” NPS, the distance should be 4”. If this is not possible, it should not be less than 1½”.

The minimum spacing of circumferential welds between centerlines shall not be less than four times the pipe wall thickness or 25 mm, whichever is greater. Here, you can see the example.

If you have branch welding on a pipe, then the distance between two adjacent branches or nearest girth weld should be four times the pipe wall thickness or 25 mm, whichever is greater. Please note that these are thumb rules and vary from company to company.

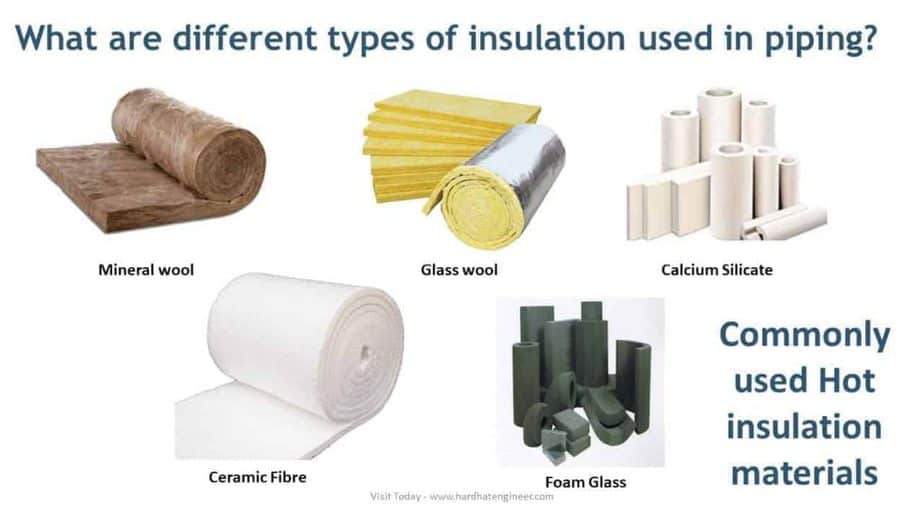

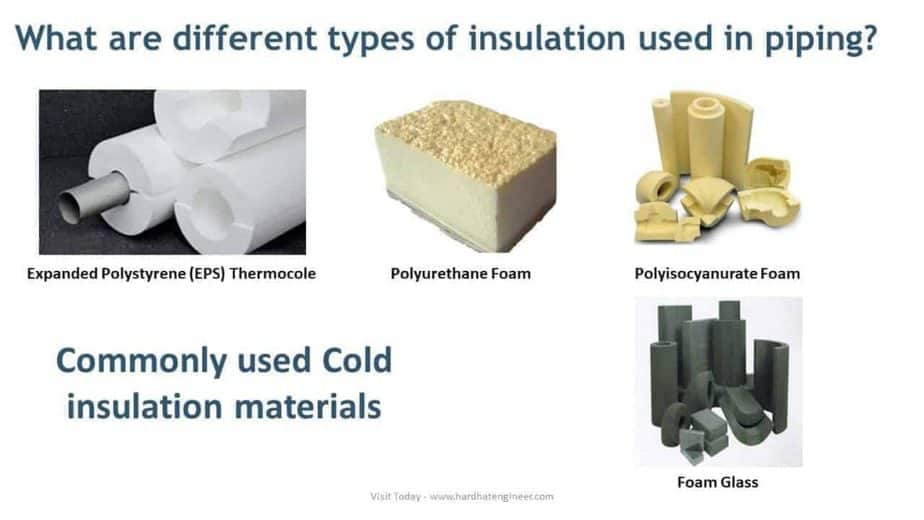

What are the different types of insulation used in piping?

You know that two types of insulations are used in the plant for the conservation of heat. First is cold insulation with a cryogenic system that prevents heating of the system and hot insulation that is used to protect against heat loss to maintain the temperature of the system.

Commonly used hot insulation materials are:

- Mineral wool

- Glass wool

- Calcium Silicate

- Ceramic Fibre

- Foam Glass

Commonly used Cold insulation materials are:

- Expanded Polystyrene (EPS) Thermocole

- Polyurethane Foam (PUF)

- Polyisocyanurate Foam (PIR)

- Foam Glass

What is the difference between GRE and GRP Pipe?

- GRP is Glassfibre reinforced plastic. GRE is Glassfibre reinforced epoxy.

- GRE/GRP pipes are used in seawater and sewage transport applications. These pipes offer excellent corrosion resistance property over all other types of pipes.

- The main difference between GRE and GRP is the resin used for bonding the glass fiber. GRP pipe used Isophthalic Resin, whereas GRE pipe used Epoxy Resin.

- GRE pipes are also used for industrial applications, as they can withstand higher temperatures than GRP pipes. GRE pipes are used in the offshore platform and water treatment plant to handle salty water.

What is the difference between the post-heating of weld and PWHT?

You can easily answer this question if you know what post-heating and PWHT are.

In post-heating, you raise the temperature of the weld joint to a predetermined temperature range (usually 250° C to 350° C) for a minimum period (usually 3 hours) before the weld cools down to room temperature. Post heating is performed immediately before the weld gets cold when welding is completed or terminated any time in between.

Post-heating is also known as Dehydrogenation as it removes entrapped hydrogen from the weld. Post-heating is done to avoid delayed cracking in the weld.

PWHT, known as post-weld heat treatment,, is performed on the completed weld to relieve the stress from the weld joint. This will soften the heat-affected zone and reduce the hardness of the weld.

Now you can answer the difference between post-heating and PWHT. Post-heating is used to avoid delayed cracking, and PWHT is used to relieve the stress from the joint.

This is the end of the video and also the end of the Piping Interview Question series. I hope you have enjoyed the videos in the series. Please do share and like these videos with your friends. Don’t forget to visit my website, hardhatengineer.com, to learn more about piping. See you soon — goodbye, take care.

Are You Piping Components Master?