Welcome to Hardhatengineer.com. I am Varun Patel. In this video, you will learn about the most common questions regarding piping that you may face during the interview.

You will learn about these questions;

- When is Low strength carbon steel bolting used?

- When are carbon steel materials used, and when will alloy steel materials be used?

- When are Galvanized Pipe used?

- From which size onwards is a pipe’s Nominal Bore equal to the Outside Diameter of the Pipe?

- What should be the radius of a long radius and short radius elbow?

- When are the long radius and short radius elbows used?

- Normally where do we use Eccentric reducers and Concentric reducers?

- From which side of the pipe will you take a branch connection?

- Why do we provide High Point Vent (HPV) and Low Point Drain (LPD) in piping?

- What is Jacketed Piping?

So please watch this video till the end. And don’t forget to subscribe to my channel; that way, you will get regular updates on new videos. You can subscribe right now by just clicking the subscribe button on your screen. So let’s start with the first question.

When is Low strength carbon steel bolting used?

There are two types of flange bolting material available. The first is low strength, and the second is high strength bolting. A flange that is used in low pressure-temperature and non-metallic flanges is connected with low strength bolting. Normally low strength bolting shall not be used above 200 degrees Centigrade or below – 28-degree Centigrade.

When carbon steel materials shell used, and when will alloy steel material shall be used?

Service fluid, pressure, and temperature will decide the type of material that can be used in a given process condition. Carbon steel materials are used for temperatures up to 425-degree Centigrade. Alloy steel materials are used for temperatures above 426 degrees Centigrade. If a fluid is highly corrosive, then stainless steel is used.

When are Galvanized Pipe used?

Carbon steel pipes are galvanized to protect them from general corrosion. You will find a galvanized pipe in services, such as potable water, instrument air, and plant air.

From which size onwards is a pipe’s Nominal Bore equal to the Outside Diameter of the Pipe?

If you have seen my earlier video on pipe size, you can answer this question easily. 14-inch onward pipe outside diameter is the same as its size. Below that, you will see that the outside diameter is more than the pipe size.

Here, I want to highlight one thing: pipe OD is fixed by standard, so if the thickness of the same size pipe change, it will reduce or increase the pipe’s internal diameter.

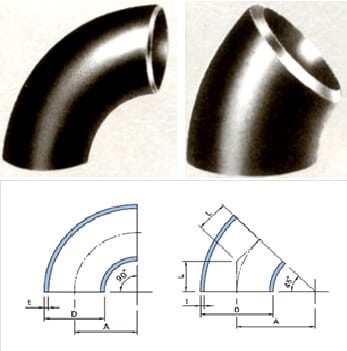

What should be the radius of a long radius and short radius elbow?

Pipe elbows are available in two different radiuses. A Long Radius elbow has a radius equivalent to 1.5 times the diameter of the pipe, and a Short Radius elbow is having a radius equivalent to the Diameter of the pipe. Here, you can see the same in the image.

- Long Radius A=1.5D

- Short Radius A=1D

Pipe FIttings Quiz – Test yourself, Take This Quiz

When are the long radius and short radius elbow used?

When fluids are transported to long distances or go through frequent directional changes, short radius elbows are not recommended because of their greater friction loss, which may require the installation of a larger pump or compressor.

So, when space is really constrained, such as piping inside the ship short radius elbow is used. In refinery and similar process plants, you will see that only a long radius elbow is used in piping.

Normally where do we use Eccentric reducers and Concentric reducers?

Eccentric reducer is used in a horizontal line where the bottom elevation of a pipe is to be maintained on a pipe rack. A concentric reducer is used in a vertical line where the center of the pipeline is to be maintained.

Here I want to highlight that the Concentric reducer is not used in the pump suction line. Because air pockets may form if a concentric reducer is used at pump suction, which results in cavitation

and causes damage to the Pump. To avoid this problem, an Eccentric Reducer with flat side up (FSU) is used in Pump Suction.

From which side of pipe will you take a branch connection?

When fluid is Gas, Air, Steam, and Cryogenic Service branch connections are provided from the Topside of the branch.

When Fluid is Liquid, a branch connection is provided from the Bottom Side. However, this is a preferred option, not mandatory. You will see lots of branches for liquid fluid is also given from the topside to meet the pipe rack condition.

Why do we provide High Point Vent (HPV) and Low Point Drain (LPD) in piping?

A high point vent is provided in the line to remove Air either during Hydro-test or during the start-up of the liquid line.

Low Point Drain is provided in the line for draining water after conducting Hydro-test or to empty the line during shut down.

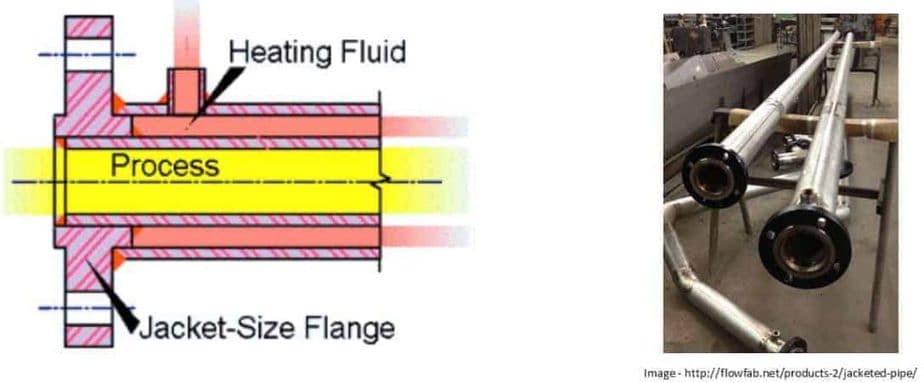

What is Jacketed Piping?

As the name suggests, in the jacketed piping, the main process line has a jacket of another pipe. In simple language, you can say that pipe inside the pipe. Jacketing is used when pipelines carry viscous fluid and require extremely uniform heat distribution.

In the image below, you can see that the outer cover has an inlet and outlet connection. Steam or hot oil is supplied in the jacket to keep the core pipeline hot. The pipelines that carry liquid sulfur inside the sulfur recovery unit of the refinery are steam jacketed. These lines are also hot insulated to prevent heat loss.

This is the end of the video. I hope that you have learned from this video. In the next video, I will explain to you a few more important questions related to piping. So keep on checking my youtube channel for new videos.

Visit my website hardhatengineer.com for free study materials, and don’t forget to subscribe to my channel to get regular updates on new videos. Please like and share my video with your friends. If you want to request a video, please write in the comment. See you soon; goodbye, take care.

Are You Piping Components Master?