In this article, you will learn about the different types of inspection certificates as per EN10204 standards. These certificates play a crucial role in ensuring the quality and compliance of steel products used in industries like Oil and Gas.

What is EN 10204, and why is it so Important?

When it comes to ensuring the quality and compliance of metallic products used in Oil and Gas industries, an inspection of materials plays a vital role.

Depending on the purchase order requirements, these certificates provide crucial information about the inspection and testing processes that steel product has undergone.

The most recognized standard for types of inspection certificates is European standard EN 10204. It is a specification for “Metallic products – Types of inspection documents.” and specifies the requirements for inspection documents.

What are the Most Commonly Used Types of Certificates?

There are four different types of inspection certificates.

- Type 2.1 – Certificate of Declaration

- Type 2.2 – Non-Specific Inspection

- Type 3.1 – Specific Inspection

- Type 3.2 – Specific Inspection by Third Party

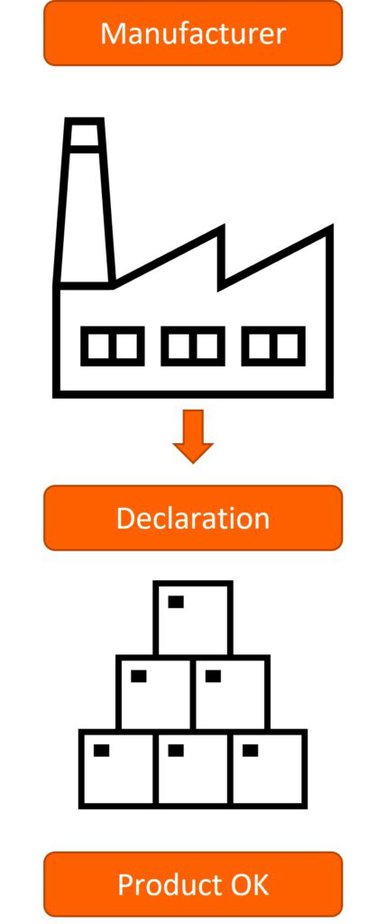

What is an EN 10204 2.1 Mill Test Certificate?

The first type is the Type 2.1 certificate. This certificate serves as a statement of compliance with the order. The manufacturer declares that the products supplied the requirements but does not provide any test results.

It is basically a declaration from the manufacturer or supplier that the products supplied have been produced according to the agreed-upon specifications, and you can trust us.

Piping Component Quiz – Test yourself, Take This Quiz

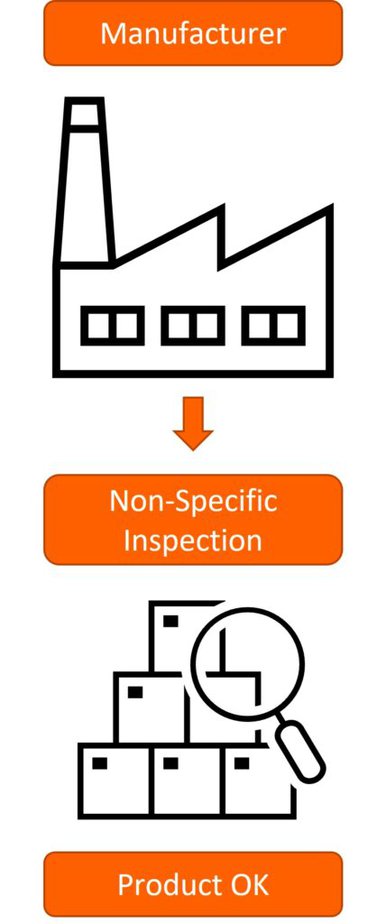

What is an EN 10204 2.2 Material Certificate Type?

Moving on to the next, we have the Type 2.2 certificate type. It also includes a statement of compliance issued by the manufacturer with the order, but it goes a step further.

It provides test results based on non-specific inspections carried out by the manufacturer. These tests are typically basic and do not cover all aspects of the product’s conformity. But What is a non-specific inspection?

Well, Non-specific inspection refers to an inspection process conducted by a manufacturer based on their own established procedures.

The purpose of this inspection is to determine whether products, which are defined by a specific product specification and manufactured using the same process, meet the requirements of the purchase order or not.

In simpler words, the manufacturer examines the products they have produced to ensure that they conform to the specifications outlined in the purchase order. This inspection is carried out using the manufacturer’s internal procedures rather than relying on any external or standardized criteria.

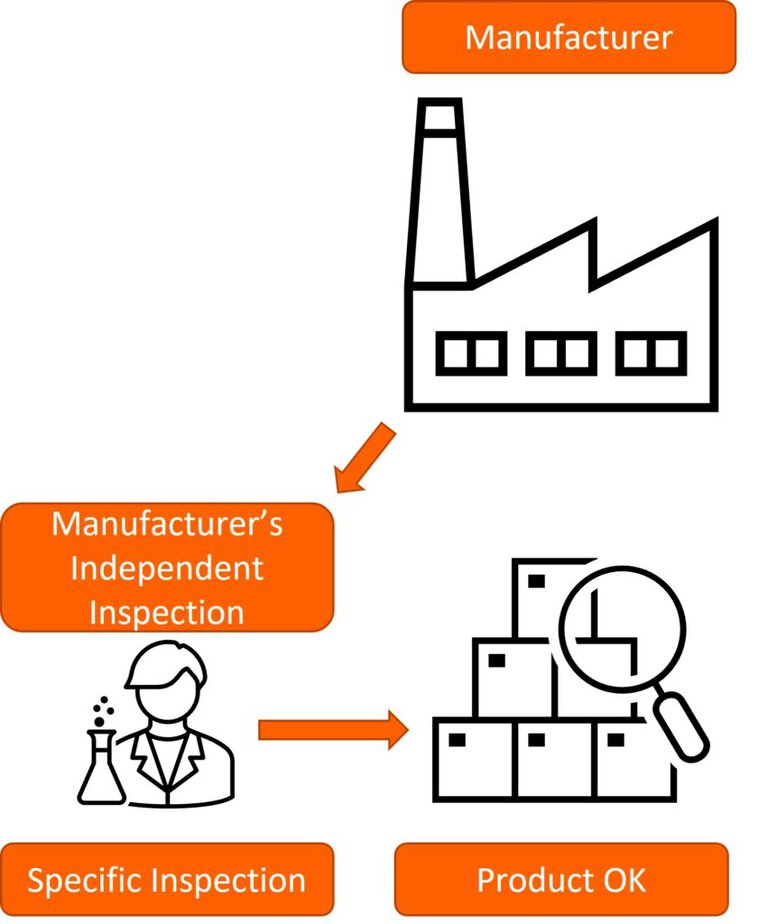

What is an EN 10204 3.1 Material Certificate?

Now, let’s talk about the Type 3.1 certificate. This is a more comprehensive type of inspection certificate that ensures a higher level of quality assurance.

It is issued by the manufacturer’s authorized inspection representative, who is independent of the manufacturing department and confirms that the products have been tested according to specific standards.

It means that all the tests and inspections are carried out and witnessed by a separate Inspection department and not by the production department.

The results of these tests must comply with the requirements stated in the material standards. The EN 10204 Type 3.1 inspection certificate may also include additional test results, providing more detailed information about the product’s conformity.

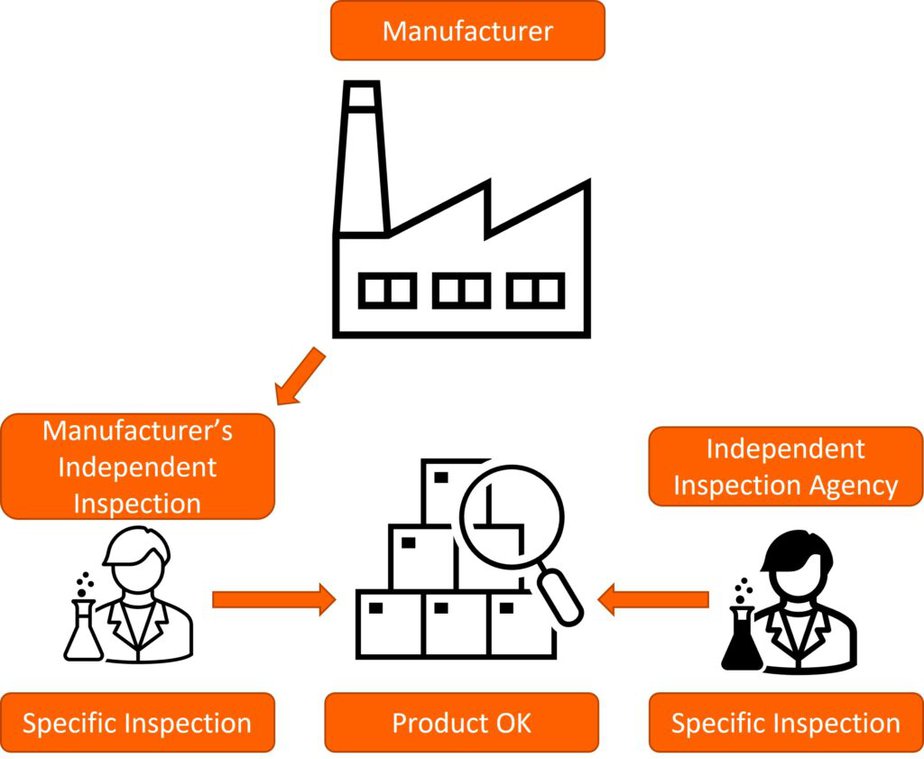

What is an EN 10204 3.2 Material Certificate?

Finally, we have the Type 3.2 inspection certificate, which offers the highest level of assurance. This certificate involves independent verification by a third-party inspection authority. This third party may be the purchaser’s authorized person or by inspector of independent inspection agencies.

To certify the material with a Type 3.2 certificate, in addition to the manufacturer’s inspection department, the third party performs and witnesses its own inspections and tests.

The Type 3.2 certificate includes test reports and statements of compliance from both the manufacturer and the third-party authority. This independent verification adds an extra layer of confidence in the product’s quality and conformity.

Please note that in the case of 3.1 and 3.2 material test certificates, inspection and testing are carried out based on the specific inspection requirements stated in the material standard, such as ASME, ASTM, or API, and not the manufacturer’s own standard.

Are You Piping Components Master?

Summary

These certificates provide crucial information about the inspection and testing processes that a product has undergone. It also ensures transparency and traceability in various industries.

Manufacturers and customers can choose the appropriate type of certificate based on their specific requirements to establish trust and meet regulatory standards.

I hope you now have a clear understanding of all 4 types of mill test certificates as per EN 10204 standards. Check this article If you want to learn how to review material test certificates in detail.